Scientists at the Fraunhofer Institute for Solar Energy Systems (ISE) have developed a new heterojunction technology (HJT) solar cell which uses “one-tenth” of the amount of silver as a standard cell.

The cell uses 1.4 milligrams of silver per watt peak of power output, Fraunhofer ISE said, which is “about one-tenth of the current standard in industrial production.” The new cell also achieved a higher conversion efficiency than reference cells with standard amounts of silver, the institute claimed.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

The development could be a significant step toward reducing silver consumption in the PV industry, which is a major challenge to the sustainable growth of solar PV deployments globally. For the last two years, the International Technology Roadmap for Photovoltaics (ITRPV) has highlighted silver reduction methods as a key trend in the industry (premium access).

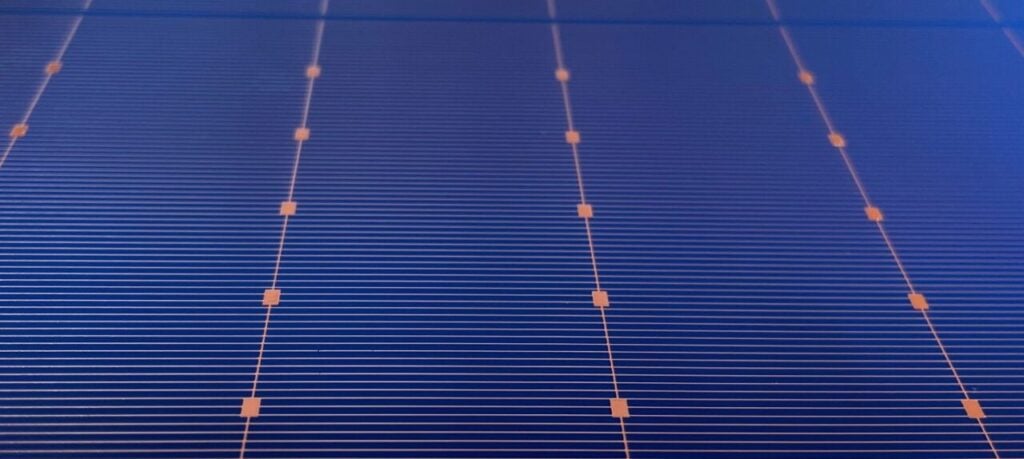

Fraunhofer’s scientists replaced silver with copper in their new HJT cell. The laboratory “strongly reduced” the silver content in the metallisation paste used on the front of the cell and “completely replaced silver with copper paste” on the rear, using screen printing to ensure “very fine electrical contacts.”

“Thanks to the balanced combination of silver-copper paste on the front side and pure copper paste on the rear side in conjunction with an optimised fine-line printing process, we were able to produce highly efficient silicon heterojunction solar cells with a minimal silver consumption of only 1.4 milligrams of silver per watt peak,” said Sebastian Pingel, research associate at Fraunhofer ISE.

“In our experiment, the solar cells even achieved a higher efficiency than the purely silver-metallised reference cells.”

The cell was developed as part of a project funded by the German Federal Ministry of Economics and Climate Protection, dubbed ‘HIT – High-quality innovative printing forms for the metallization of silicon heterojunction solar cells’. The project also included struggling Swiss solar manufacturer Meyer Burger as an industrial partner.

Fraunhofer ISE said: “To enable PV production on a multi-terawatt scale, solar cell and module manufacturers must significantly reduce their silver consumption.” According to the Silver Institute, solar PV manufacturing accounted for 32% of worldwide industrial silver consumption in 2024. N-type cells, which have become mainstream technology among the major Chinese solar manufacturers, have greater silver requirements than older tech, which suggests that the industry’s silver consumption will only increase unless manufacturers find ways to reduce their reliance on the metal.

PV Tech Premium examined the financial impact that exposure to silver prices can have on solar manufacturers