‘Silicon Module Super League’ (SMSL) member GCL System Integrated Technology (GCL-SI) has officially started production at its joint venture (JV) solar cell plant with Vina Solar in Vietnam as well as an unmanned module assembly pilot project in China.

The new facility has a nameplate capacity of 600MW and includes 330MW of initial PERC (Passivated Emitter Rear Cell) capacity. The company had earlier announced that German-based PV systems supplier IBC Solar was being supplied 60MW of solar modules from Vietnam for projects in Europe with deliveries starting in September, 2017.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

GCL-SI also said recently that its use of diamond wire cutting of the polysilicon wafers wet chemical ‘Black Silicon’ texturing of PERC cells had achieved average conversion efficiencies of 20.3%. Modules using the wafer and cell technology were producing on average 290W. The target for the fourth quarter of 2017 was to reach average cell efficiencies of 20. 5%.

Shu Hua, president of GCL-SI said, “GCL's high-efficiency PERC production line in Vietnam, based on the localized management, will offer a strong support to the high-efficient cell supply and contribute to cost-down as well as voiding anti-dumping issues.”

Unmanned module assembly tests

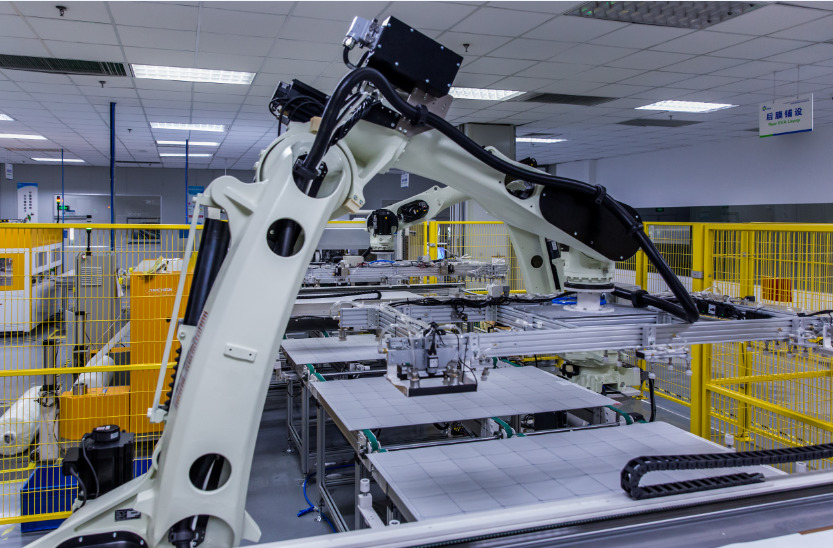

GCL-SI has also recently established a module assembly workshop that is completely unmanned to test intelligent fully automated manufacturing tools and software systems, which is expected to undertake tests for around two years.

The company noted that it is cooperating closely with Chinese domestic equipment manufacturers, and has independently developed and researched and developed a series of intelligent equipment and systems, which included high-speed automated tabbing machine a high-precision layout machine and robot palletizing system, In all, GCL-SI said that 26 separate systems so far developed were industry firsts.

A key aim of the tests is to achieve a 50% improvement in efficiency, a 60% reduction in online manpower and reduced processing costs by 30%. Product quality improvement targets were being set at a 21% overall improvement.

The intention is to implement the improvements across its volume manufacturing operations.