Green fuels developer InterContinental Energy has patented a green hydrogen production technology that it claims can reduce costs by 10-20%.

The technology will be used in a proposed 70GW solar PV, wind, and green hydrogen project in Western Australia.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

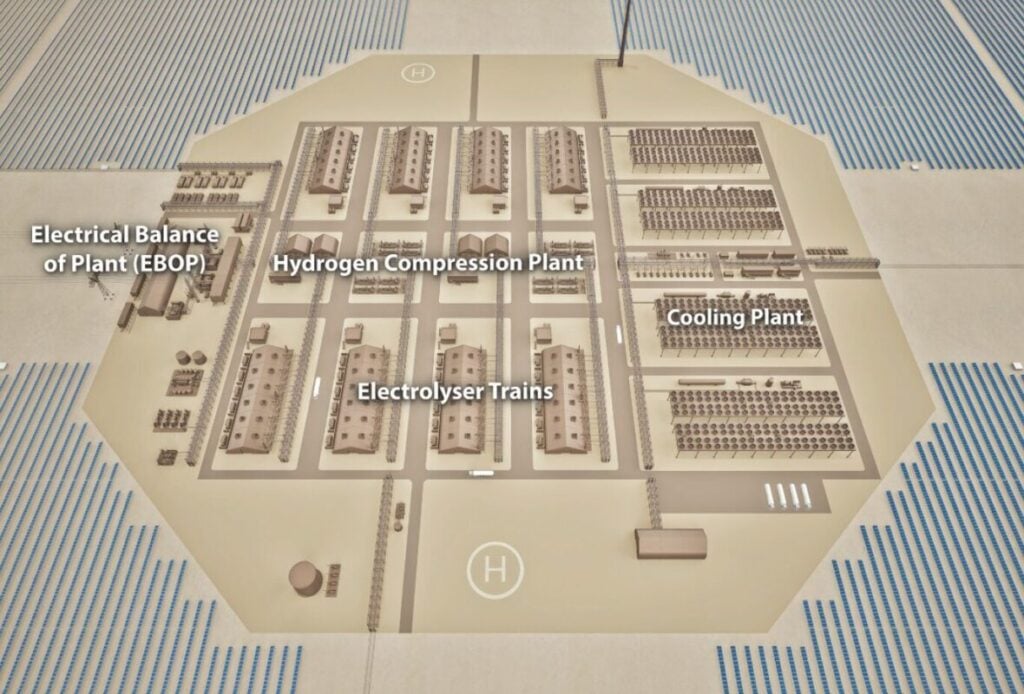

The newly patented P2(H2)Node system, designed in Australia over four years, aims to support the development of gigawatt-scale green hydrogen production projects globally.

According to the organisation, the P2(H2)Node standardised architecture will “streamline the green hydrogen industry by replacing bespoke projects with a uniform approach.”

It aims to reduce green hydrogen production costs by essentially stripping the need for expensive electricity transmission. Instead, the patented system co-locates giga-scale green hydrogen production facilities with variable renewable energy generation, namely solar PV and wind. Removing transportation costs helps bring down the overall cost of green hydrogen.

The company claims up to 10% less CAPEX through standardisation, modularity, reduced electrical infrastructure, and reduced storage requirements and up to 10% more efficiency through design optimisation and elimination of very high-voltage power equipment.

Alexander Tancock, CEO at InterContinental Energy, said the technology is a breakthrough for green hydrogen production globally.

“We are proud that our team in Perth has developed this globally significant technology. The P2(H2)Node architecture is a breakthrough in clean hydrogen production. By eliminating transmission losses and leveraging a modular approach, we are making green hydrogen cost-competitive at scale for the planet,” Tancock said.

“This technology comes at a time when Australia is poised to become a global leader in e-fuels and green iron.”

Green iron and broader green metals have been touted as a huge economic opportunity for Australia, particularly Western Australia. PV Tech Premium recently delved into the topic, featuring voices from Fortescue, Clean Energy Finance, and more.

P2(H2)Node to be used in 70GW renewables mega-project in Australia

Another key revelation from InterContinental Energy is that the P2(H2)Node system is set to be utilised within the Western Green Energy Hub (WGEH), a 70GW solar PV and wind project.

The AU$100 billion (US$65 billion) project is being pursued by project developers WGEH. The developer inked a collaboration agreement in September with Korea Electric Power Corporation (KEPCO) and submitted the project to Western Australia’s Environmental Protection Authority (EPA) in November 2024.

According to planning documents submitted as part of an EPBC Act application, the project will adopt a ‘nodal’ approach by clustering around 2-3GW of wind and solar PV, with a 1.5GW electrolyser and a data centre located at the centre of each node. In total, around 35 nodes will be constructed.

The developer also claims that the annual energy produced from the megaproject will be over 200TWh, which is similar in magnitude to Australia’s current generation. As such, WGEH believes the project could play an essential role in energy trading with international partners.

It is worth noting that the hub would be built in phases to produce up to 3.5 million tonnes of green hydrogen per year, which would be provided domestically and internationally by being converted into green ammonia.