Since its founding in 2010, inverter manufacturer Growatt has been on an international trail that has seen it establish branches in 14 countries and regions including Germany, the US, the UK, Australia, Thailand, India and the Netherlands to serve global customers. Its overseas markets accounted for between 60 – 70% of its total business last year.

But it is at home where much of the company’s focus has been in the first six months of 2020, constructing a new factory – where the company is expected to move before the end of the year – and readying new product launches for various demographics.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

PV Tech interviewed Lisa Zhang, marketing director at Growatt, to get the insider track on the company’s strategy.

PV Tech: 2019 witnessed a lot of changes across the industry, what were Growatt’s highlights last year?

Lisa Zhang: Some growing overseas markets emerged in 2019. For example, the residential markets in Latin America, Europe and Australia, and we accelerated the process of building up our overseas marketing teams to expand our global footprint. We did very well in both the new overseas markets and the traditional ones in 2019. According to the IHS Markit and Wood Mackenzie inverter reports, Growatt was a global top 10 player, ranking third in single-phase inverter shipments, and listed among the top five in shipments of three-phase inverters.

PV Tech: How has COVID-19 impacted your overseas business? What steps have you taken to cope with the pandemic?

Lisa Zhang: This year we are growing steadily. The pandemic hasn’t drastically affected the distributed market. We’ve worked hard to ensure that, when manufacturing is restarted, our plant capacity can satisfy market demand. The factory was not running at full capacity in March, but in late April we were able to catch up. Growatt is a typical Shenzhen company, known for its efficiency!

What’s difficult about the overseas market is that we haven’t been able to meet our customers face-to-face, so we’ve resorted to various online initiatives such as training, demand surveys and service follow-up. Generally speaking, thanks to the varied channels and our overseas customer base, our overall operation hasn’t been affected too much, as most of our customers are well-established companies capable of mitigating risk.

Our factories are now operating at near full capacity to serve both the domestic and overseas markets. Despite the pandemic, H1 results have highlighted a continual increase in domestic shipments and tremendous progress in Poland, Brazil and Australia.

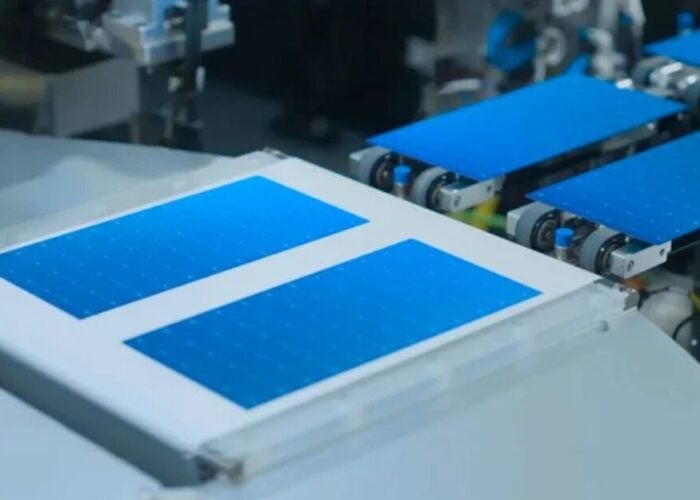

The ever-expanding global business is demanding higher and higher output and Growatt is building a new factory to handle this situation.

PV Tech: July marks the beginning of H2, 2020. What new products will Growatt be launching over the next six months to a year?

Lisa Zhang: Growatt is a company which, since its foundation, has been dedicated to innovation and R&D. We are always quick to pick up on the latest trends in distributed and large-scale projects, based on our observations of the market and technology. We’re planning to introduce the 750W-253kW Generation X inverters later this year to cater for such changes. Featuring improved performance, safety, smart control and appearance, the new inverter is smaller and lighter, with an optimized internal design. The residential inverter is aesthetically pleasing, with both this and the C&I inverter rich in functionality. The AFCI and SPD solutions help structure a safer and smarter system, and our various monitoring solutions, able to remotely monitor and control the system for O&M, make it smarter.

In addition, we will be launching a 1500V string inverter in H2 for large-scale PV projects, further cementing our advantages in this field.

In the future, PV storage will play an increasingly important role in the renewable sector. The storage solutions developed by Growatt are presenting more competitive products and a one-stop service for our customers. To complement the Smart Home energy management solution, our R&D team is also actively researching into the IOT, big data and AI technology for system innovation and upgrade.

PV Tech: The new factory under construction – how is that progressing and what is the planned capacity?

Lisa Zhang: We are looking to the future and that’s why we’ve decided to build the new factory in Huizhou city. It is all about enhancing and maintaining sustainable production. Boasting a complete supply chain, Guangdong province is a booming hub for electronic products. Building a new factory will facilitate our supply chain management and help guarantee product quality. It is a strategic move. We hope to greet our customers with a brand new look when this new factory is complete.

PV Tech: What is the planned capacity and floor space of the new factory?

Lisa Zhang: It covers an area of 200,000 square meters, incorporating an administrative office, staff dormitories, an entertainment venue, an exhibition hall, warehouses, a freight centre and advanced, integrated production lines. Its annual output is expected to be around 10GW and we plan to move in by the end of the year.

PV Tech: Going back to product strategy, your business scope covers residential, distributed C&I and storage. Which of these is the priority for Growatt?

Lisa Zhang: Traditionally, and in view of the current progress, our business can be divided into the following segments. The first one is inverters for the distributed residential and C&I markets. It is a mature business sector for Growatt and we’re very experienced with products in this category. We’ve come up with different solutions specific to different markets for upgrading and innovating products.

The second segment is residential storage and virtual power plant, where we’ve made an early start. Growatt has invested heavily to develop new products and deliver an integrated one-stop solution.

Up to now, we have done well in overseas storage markets, such as Australia and Italy. We are also exploring the German and Japanese markets. According to Wood Mackenzie, our share of the residential storage market put us in the top two globally last year.

The third segment is the ground-mount market. We plan to introduce the new 1500V series for ground-mount plants at SNEC this year. We will also promote it in Southeast Asia, America and Europe. Growatt has a proven track record in ground-mount plants, but this is not a big part of our business at the moment. We are looking to further expand in this area.

PV Tech: What’s your view on current progress and technology trends in the inverter industry?

Lisa Zhang: Firstly, as the importance of renewables is obvious to everyone, I am very optimistic about prospects for the PV industry. Additionally, with falling system costs, it is inevitable that PV will head towards grid parity where its advantages can be fully brought into play.

With increasing PV installations and the growing popularity of EV, we are convinced that PV storage will turn out to be another important trend.

The distributed PV sector will find wider applications. BIPV, the technology integrating PV and buildings for example, will become a trend-setter. Finally, let’s come to smart O&M. There is a lot of room left for developing such technology in the PV industry. How to reduce O&M costs by remote means and big data analysis? I think there is still a long way to go.

PV Tech: Are there any unique BIPV requirements for inverters?

Lisa Zhang: At present, it is typically about the module. Modules need to be installed on top of the building and the technical requirements are more stringent. There are still many standards and specifications to be spelled out within the industry. The inverter needs to be matched with the module, and the electrical specification needs to be adjusted accordingly once the module specification is fixed.

PV Tech: Is it possible that the integrated PV power project, inverters included, will become a brand new market sector, following the growth in BIPV?

Lisa Zhang: Only using the inverter as an electronic device in the PV industry is, in fact, quite limited. Taking UPS for example, they are also called inverters and can be used in many scenarios by IT and financial companies, data centers as well as steel and coal industries. PV is only one of such applications. If BIPV is to thrive in the future, the business scope will be further expanded just as the market size. We are quite looking forward to that.