LONGi Solar has introduced its next-generation series of large-area high-performance modules for utility-scale PV power plant markets globally. The new Hi-MO 5 Series offers up to 540Wp performance with gallium-doped, newly defined M10 (182mm x 182mm) wafers, half-cut monocrystalline PERC (Passivated Emitter Rear Cell) cells and 9BB (busbar) ‘Smart Soldering’ cell interconnect technology.

Problem

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

In the era of grid parity and project bidding, PV module performance is rapidly expanding to provide significant levelised cost of energy (LCOE) and balance of system (BOS) cost reductions. As a result, large-area wafers, coupled to innovations at the cell and module level, need to be compatible with PV inverters and tracker systems, notably for bifacial systems. However, the idea that the larger the module size, the better, is questionable for various real world and practical reasons.

Solution

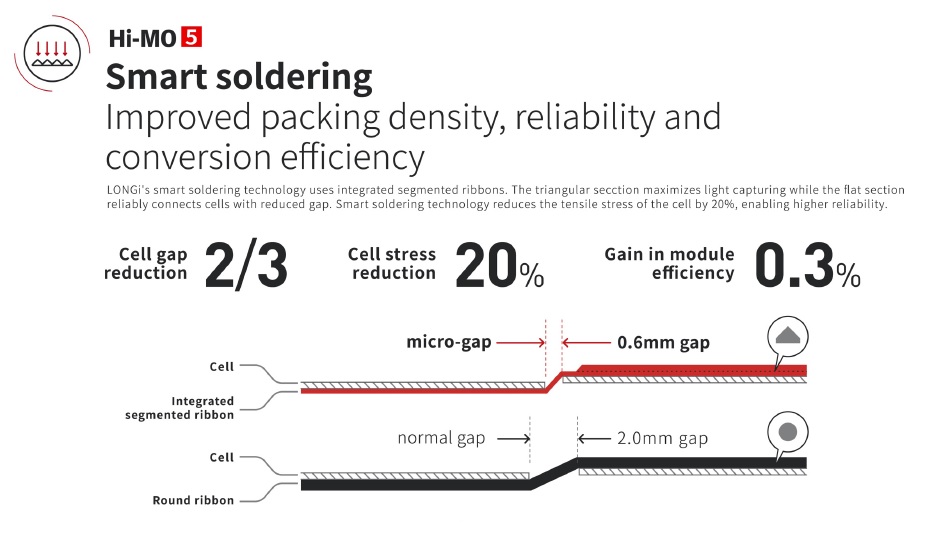

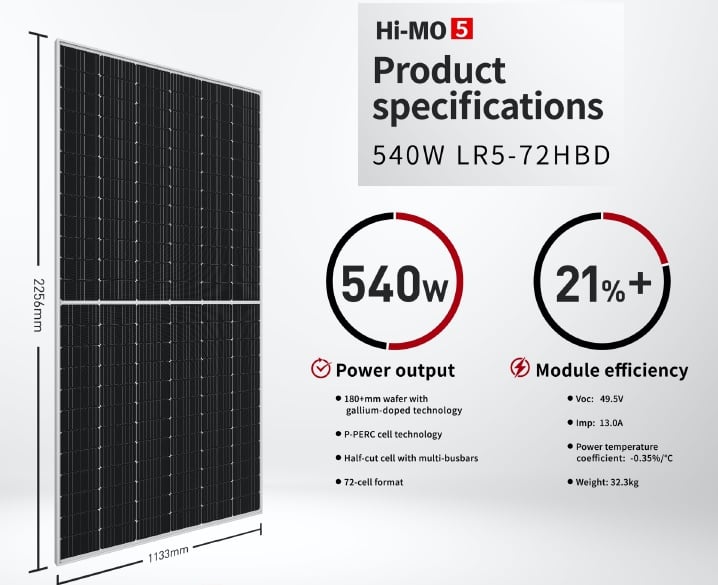

Hi-MO 5 modules deploy gallium-doped M10 (182mm) wafers, which provide better security against LID (Light Induced Degradation) with stable, long-term power generation. LONGi’s proprietary ‘Smart Soldering” technology uses integrated segmented ribbons. The triangular ribbon design maximises light trapping, while the flat section reliably connects cells with reduced spacing. As a result, the Smart Soldering technology reduces the tensile stress of the cell by around 20%, as the cell interconnect gap is reduced to approximately 0.6mm, compared to standard spacing of around 2.0mm. This leads to improved packing density, reliability, and conversion efficiency. Compared to LONGi’s existing Hi-MO 4 module series, the increase in module power can be attributed to the increase in the Isc (short circuit current), while the Voc (open circuit voltage) is unchanged at approximately 13A, enabling the module to operate correctly with the current range of advanced 15A PV inverters, negating potential power losses. The power in one string is significantly improved, resulting in a reduction in BOS cost. Overall, with front-side power up to 540W, 21.1% conversion efficiency and module size of 2,256mm ×1,133mm, Hi-MO 5 provides the best-in-class BOS and LCOE for large scale PV power plants, according to the company.

Applications

Hi-MO 5 (72-cell) is designed to provide the lowest LCOE for utility-scale PV power plants. Hi-MO 5 also has an option for a 66-cell type layout (up to 495W). The lower Voc and shorter module length broaden applications for this product option.

Platform

The Hi-MO 5 Series modules are constructed in a double glass with frame format and maintain the traditional 6 row design in the 72C layout. The module dimensions are proposed at 2,256mm x 1,133mm. The height of the shipping container limits the module width to about 1.13m. The length of the 72-cell Hi-MO 5, at about 2.25m, is also compatible with many racking systems available on the market from 1P to 2P designs. The dual glass bifacial module has increased load capacity and is qualified for 5400Pa static load on the frontside when there is no crossbeam used on the backside of the module, avoiding shading losses. With the gallium-doped cells, Hi-MO 5 offers increased attenuation and power performance and long-term reliability. The 1st year power warranty is an industry-leading 98% and linear annual attenuation is within 0.45%. Concurrently, Hi-MO 4 continues as a current product in LONGi’s portfolio. Hi-MO 4 is best suited for applications in residential, C&I rooftops and power plants. Hi-MO 4 and Hi-MO 5 will co-exist in LONGi’s product lineup.

Availability

Hi-MO 5 will be produced in volume and receive IEC/UL certification in September 2020. LONGi Solar’s production capacity for Hi-MO 5 will reach 12GW at the end of 2020. First shipments will be supplied to utility-scale PV power plants. Hi-MO 5 entered volume production on 8th September, 2020.