Solar PV modules based on 210mm cells produce the best levelised cost of energy (LCOE) and deliver improved balance of system (BOS) costs, according to an evaluation conducted by independent advisory DNV GL.

The evaluation, conducted under an invite from ‘Solar Module Super League’ (SMSL) member Trina Solar, concluded that modules featuring 210mm cells have a “prominent edge” over other products in delivering benefits to project developers.

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

As part of the study, DNV GL compared the performance of a Trina Solar 545W bifacial dual-glass Vertex module against those in 166mm, 450W and 182mm, 535W classes.

It used two typical solar sites for the assessment, one in Seville, Spain and the other in Texas, the US, with each site given a nominal, fixed capacity of 100MWac, the same DC/AC ratio design and the same system design metrics: single-row, 1P tracker lay-out with string inverters.

For the basis of the study, all trackers and inverters used in the modelling were mainstream products, and all costs associated with the projects were based on localised costs for a “consistent, comprehensive and objective” survey. The ground cover ratio was also fixed in order to ensure consistent shadowing for the bifacial module. The modelling also set out to make objective comparisons between the performance of the modules, highlighting any impact on costs and the LCOE performance of each.

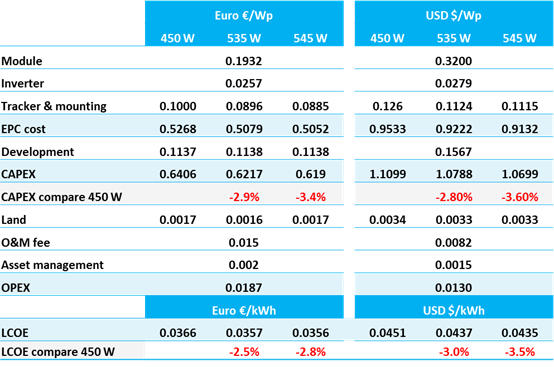

The modelling study found that on the site in Spain, Trina’s Vertex 210mm bifacial dual-glass module produced an initial investment saving of €0.02c per watt, reducing the LCOE of the site by around 3% compared to the 166mm bifacial dual-glass 450W version. Compared to the 182mm 535W module, while the initial investment savings remained similar, the LCOE improvement was reduced to 0.3%.

At the site in the US, compared to the 166mm bifacial dual-glass 450W module, Trina’s 210mm Vertex module produced an initial investment saving of US$0.04c per watt and reduced LCOE by around 3.9%. In comparison to the 182mm bifacial dual-glass 535W, again the savings were reduced, with initial investment falling by about US$0.01c per watt and the LCOE reduced by 0.5%.

“With the further optimisation and extension of the tracker length, the 545W Vertex 210mm-Module will save more in BOS cost and LCOE than the other two modules, giving it more edge,” DNV GL said.

A summary of the respective site and module performances can be seen below.

In addition, Trina Solar, DNV GL and inverter supplier Sungrow last month co-hosted a PV TechTalk webinar on the subject of site performance utilizing the 210mm Vertex series modules, assessing the impact trackers and inverters can deliver higher power per string and deliver better LCOE per project.

That webinar can be streamed on-demand here.

Trina Solar said members of its 600W+ Photovoltaic Open Innovation Ecological Alliance were collaborating on a design mindset that paired low voltage, high string power, modules, trackers and inverters in what is to be a “critical step” for the solar industry reaching more advantageous LCOEs.

Late last month, a consortium of solar module, cell and wafer manufacturers, of which Trina Solar was one, issued a call for further standardisation of wafer, cell and solar module designs, indicating a more uniform approach would deliver the “best possible scale” for the solar industry.