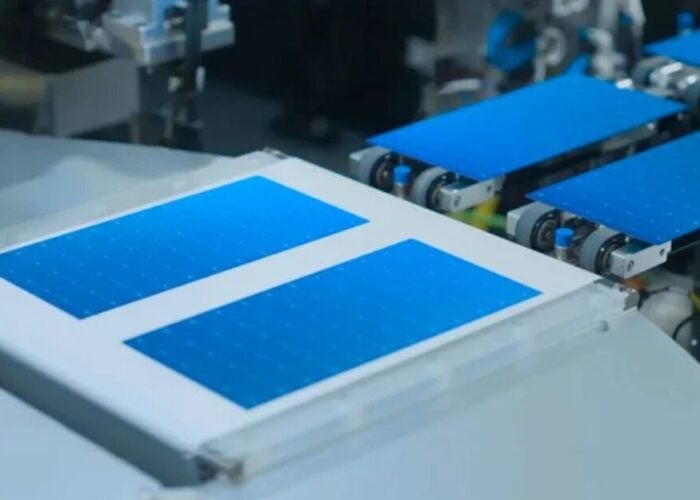

Product Briefing Outline: Vistrian have released version 5.0 of their ‘FactoryLOOK’ software platform. FactoryLOOK is a Manufacturing Intelligence System used by a number of companies including manufacturers of Solar, Semiconductor, Led, Data Storage, Networking, and Electronic assembly. The software allows for the immediate alerting and identifying of process anomalies and the ability to quickly identify factors affecting the development or manufacturing process and its variables.

Problem: There is an increased need for manufacturing intelligence solutions that allows users to collect and analyze real-time process data and interpret, aggregate, calculate and deliver a single dashboard view of relevant events, alerts and Key Performance Indicators (KPI’s) required for making timely manufacturing decisions.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

Solution: FactoryLOOK is used as a tool to integrate all processes and equipment data and to provide access to all users using a web browser. This includes the Facility, Environmental, Tooling, Test Equipment, Flat Files, Legacy systems (MES, ERP) and Operator interfaces. The tool set features provide analysis, alerts, dashboards and reports using the integral rules engine in real-time, thus providing the user with timely information to optimize operations and processes. The software integrates enhanced dashboards, a user configurable rules engine and the ability to be utilized in virtually any type of industry or process with modest configuration changes. FactoryLOOK 5.0 stores and archives ALL collected data for use in query analysis. Vistrian configures all elements of FactoryLOOK 5.0 without the need for 3rd party or internal IT department resources thus significantly reducing implementation cost.

Applications: Both high volume and pilot production environments to increase yields, reduce process and development time and increase process uptime through significantly increased visibility to the process and the variables that affect it. FactoryLOOK has also found a common application for the monitoring of offshore manufacturing sites and vendors.

Platform: When implemented in a manufacturing plant, each piece of monitored equipment is equipped with a Vistrian Spider. The Spider is an appliance that is equipped with a variety of data input interfaces including analog inputs, digital inputs, serial, USB, as well as Ethernet ports. Equipment and process data is thus accessible to the Spider. Data is then pre-processed by the Spider’s on-board CPU and then sent over the LAN to the FactoryLOOK server that is typically located in a server rack remotely. Powerful data analysis and charting technologies are then applied to the preprocessed data in order to provide usable and friendly charts and graphs to aid the user in managing the day-to-day running of the plant and to maximize the performance of the entire operation.

Availability: Currently available.