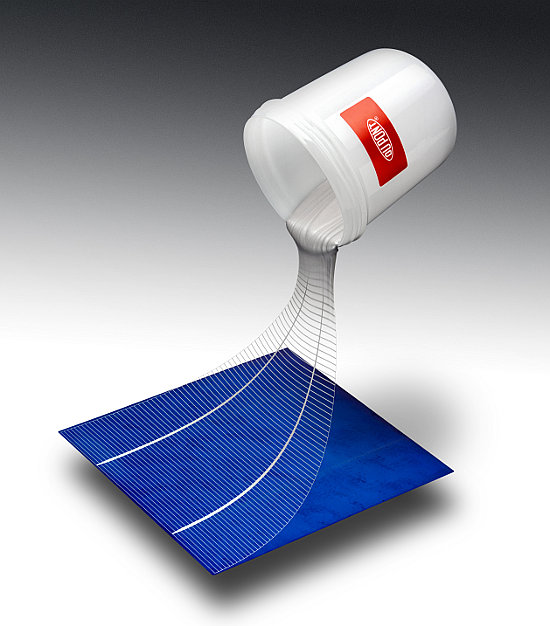

DuPont Photovoltaic Solutions is a well-known supplier of specialty materials to the solar energy industry, especially with its ‘Solamet’ photovoltaic metallization pastes that improve cell efficiencies and the ‘Tedlar’ PVF film-based backsheet materials for modules.

The company returns as a key sponsor and supporting partner of PV CellTech in Penang, Malaysia and will be active in presenting and moderating at the event. Indeed, it would be amiss not to mention that Dr. Homer Antoniadis from DuPont Photovoltaic Solutions is on the PV CellTech technical advisory board since its inception.

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

Having served the PV industry for around 40 years, DuPont is a pioneer in metallization pastes and serves the industry on a global basis. This poses unique challenges as well as opportunities for the company not least in meeting customer requirements across all solar cell architectures and the growing regions of the world where solar cell development and production are taking place.

DuPont therefore has to remain technology agnostic rather than focusing on picking niche markets or staying blinkered to the mainstream volume markets. However, being in such as position does provide insight into the evolving technology trends.

Mike Barker (Pictured), R&D Manager – Asia Pacific, DuPont Photovoltaic Solutions will be presenting on new metallization paste developments and roadmaps for solar cells, highlighting the evolution of cell technology & its impact on metallization paste development.

Ahead of PV CellTech 2017, PV Tech talked to Dr. Daniel LeCloux, R&D Director & CTO, DuPont Photovoltaic Solutions who will also be attending the event and moderating one of the sessions.

What key trends in cell technology adoption are you seeing at the moment?

The move to higher efficiencies continues across the PV industry. There is still an important focus on mainstream P-type cells with LDE (Lightly Doped Emitter) that still have an important role to play for improving efficiencies and lowering cost.

P-type LDE is also benefiting from fine line and ultra fine line technology that can also be used on different cell technologies to boost efficiencies.

But for higher efficiencies this will be PERC (Passivated Emitter Rear Cell). PERC is probably going to be the most important technology over the coming years and keeping up with these developments is therefore important. PERC allows the industry to capture the higher efficiencies at lower cost and risk.

Although N-type mono-based technologies have costs significantly higher than [P-type] LDE, programs such as ‘Top Runner’ in China are pushing companies to innovate in higher cell efficiencies and provides opportunities.

PV manufacturing is becoming increasingly global and after several years of anticipation, countries such as India are finally expanding. What does this mean to DuPont?

Developments in India both upstream and downstream markets were great to see in 2016. Like other developing regions we put resources in the right places to support our customers. We expand our presence accordingly to help customers get the most out of their cell efficiencies. I firmly believe that we need to be in the customer fabs as we need to know what exactly their needs are and provide solutions to their processing problems on an individual basis.

This means that we develop long-term partnerships with our customers and the long-term commitment to R&D investments serves the PV industry.

To view the final PV CellTech agenda updates please click here and a final analysis of the event from Finlay Colville, you can click here. To register for the event, click here.