PV Cycle, a not-for-profit compliance and waste management programme solar PV technology in Europe, has achieved a record recycling rate of 96% for silicon-based PV modules.

Previous records stood at around 90%, a PV Cycle spokeswoman told PV Tech.

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

Now one of PV Cycle’s Europe-based recycling partners for silicon-PV modules is using a new process that combines mechanical and thermal treatment to recycle silicon flakes as well as recycling a combination of EVA laminate, silicon-based semiconductors and metals.

The spokeswoman said: “Previously there hadn’t been viable solutions for the further recycling of silicon flakes. The silicon flakes could be used for the production of new products or materials, but could not be further recycled in an environmentally and economically sound manner.”

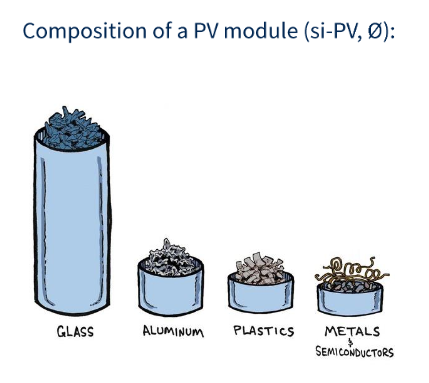

The overall recycling process for a PV module begins with the removal of the frame, junction box and cables. The module is then shredded followed by sorting via a laser-based selection or vibration procedure. The final step involves refining and micro recycling the materials such as the silicon flakes.

PV Cycle’s new process now brings recycling rates of the silicon-based modules up to 96%, meaning that it has surpassed industry and Waste Electronics and Electrical Equipment (WEEE) standards, the company claims.

The remaining 4% that is not recycled tends to be made of some residues from the glass recovery and EVA foils. These are sent for energy recovery, which is a form of waste-to-energy technology.

A PV Cycle statement said that all kinds of PV technologies are equally suitable for recycling including silicon, CdTe, CIGS and flexible modules. The organisation also listed various benefits including recovering raw materials and conserving natural resources. It said glass, aluminium, copper, plastics from the cables and junction box, certain semiconductors as well as silver can be recycled

While PV Cycle’s new record accounts for silicon-based modules, the current industry average for recycling non-silicon based modules stands at 97% although rates of up to 98% have been achieved by PV Cycle.