Korean-owned solar manufacturer Hanwha Qcells has posted a “world record” efficiency reading for an industrial-sized perovskite-silicon tandem cell.

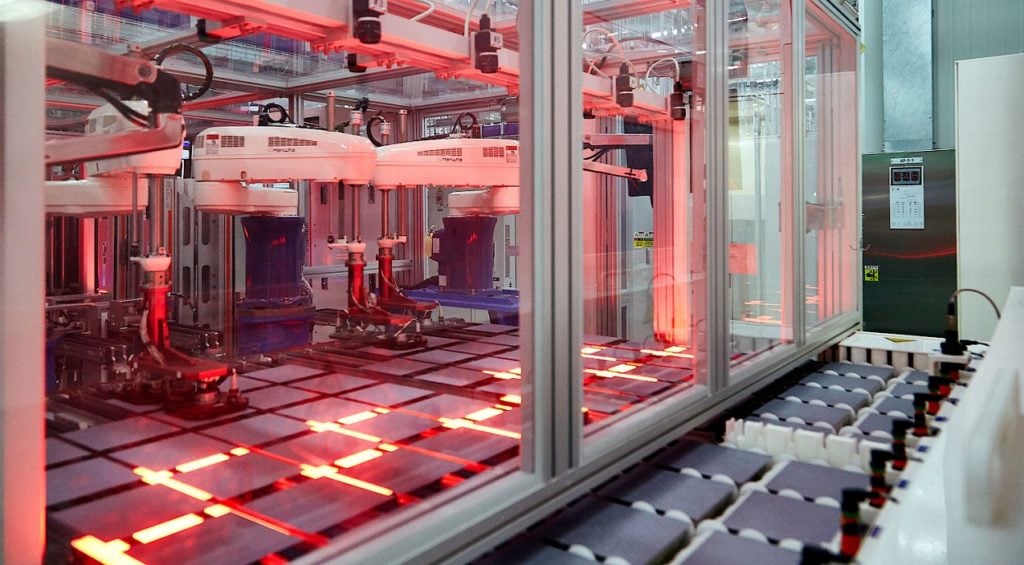

The 28.6% efficiency rating was certified by the CalLab at the Fraunhofer Institute for Solar Energy Systems (ISE). The cell – which is a full M10-sized product of roughly 330.56 cm2 – was produced at Qcells’ research and development (R&D) pilot line in Germany.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

The current industry standard for perovskite-silicon tandem configurations places a thin perovskite material layer directly on top of a silicon base cell, known as a “two-terminal tandem.” The perovskite—which can be fine-tuned to suit a manufacturer’s needs—can absorb more high-energy light than silicon and can boost cell conversion efficiency when paired with the bottom cell.

Some companies are pursuing “four-terminal” tandem configurations, where the silicon and perovskite cells are encapsulated separately and then layered.

Qcells’ two-terminal product used its proprietary Q.ANTUM cell technology as the bottom cell – a passivated emitter rear contact (PERC) silicon cell.

Robert Bauer, head of Qcells R&D in Germany, said the record-breaking cell was “based on our in-house developed perovskite technology as a top cell, and cost-efficient Q.ANTUM silicon technology as a bottom cell. The champion cell is a typical cell from our R&D pilot line in Germany and has been fabricated by exclusively using processes that are feasible for mass production. This result is laying the groundwork for future commercialisation of this exciting technology.”

Qcells said its German R&D centre in Bitterfeld-Wolfen is financially supported by the German government and the European Commission through the PEPPERONI perovskite research project. The company is one of the leaders of the PEPPERONI project, alongside research institute Helmholtz-Zentrum Berlin (HZB), which aims to pursue scalable research for the commercial manufacturing of perovskite tandem products.

Last week, six Fraunhofer institutes published research which said that perovskite-silicon tandems were the “prerequisite” technology to reach the next generation of solar cell and module technology. The five-year research project said perovskite was the leading technology for tandem cells, though it failed to find an alternative to the use of toxic lead in the cells’ production.

Perovskite-silicon tandem products have yet to be mass-produced because the material degrades at far higher rates than silicon when removed from controlled laboratory conditions. Earlier this year, British perovskite company Oxford PV shipped what it called the first commercial tandem modules from its manufacturing line in Brandenburg, Germany.

Earlier this week, we published the 41st edition of PV Tech Power, our downstream industry journal. The cover feature examined the “hope and hype” of perovskite solar technology, where we spoke with leading figures from the PEPPERONI project, Oxford PV and the US National Renewable Energy Laboratory (NREL) alongside sceptics of perovskite-silicon tandem technology.