Solar manufacturer Qcells has partnered with Lumet, a specialist in solar cell metallisation technology, to reduce the cost of its cell production lines.

Under the deal, Lumet said that Qcells would be the “world’s first” PV manufacturer to deploy its fine-line metallisation technology. The company claims that this technology can increase efficiency and reduce the cost of solar cells by reducing the amount of silver.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

Metallisation is the most expensive part of solar cell production, in part due to the cost of silver. Earlier this month, researchers at the German PV testing institute Fraunhofer ISE published a paper looking into methods to reduce silver usage in solar cells. It forecast that the PV industry could account for “up to 90%” of global silver production by 2030.

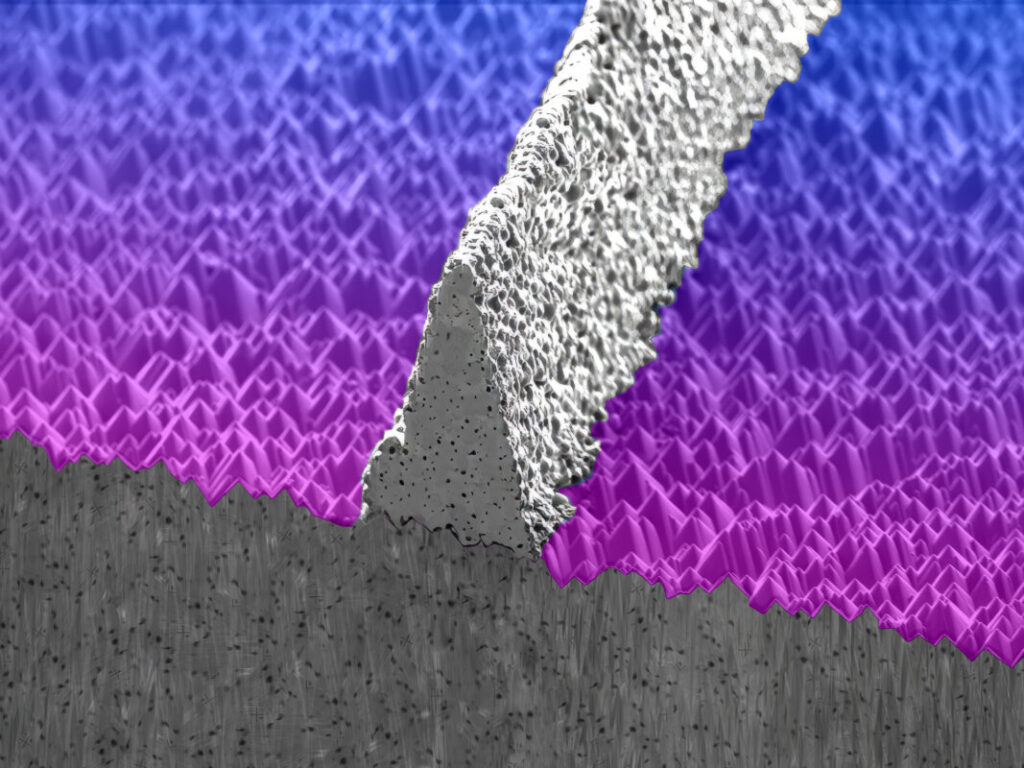

Lumet claims that its Fine Line metallisation process can enable cell manufacturers to “attain both higher cell efficiency and lower cost” by reducing the thickness of the silver fingers.

The traditional metallisation process—involving screen printing silver fingers onto the surface of the cell—has “plateaued” with finger widths of around 20 microns, Lumet said.

By contrast, its new process can produce silver fingers of sub-10 microns, which reduces the production cost by using less silver and increases cell efficiency by decreasing shading.

Last week, PV Tech Premium published a feature on rising global silver prices over the last year and their impacts on PV developers and manufacturers, particularly in China.

Danielle Merfeld, EVP and global chief technology officer at Qcells, said: “We see tremendous potential in the Lumet metallisation technology, which is a breakthrough on multiple fronts, setting records for finest lines, lowest cost, highest efficiency, highest speed and smallest footprint.”

“Moreover, with Qcells’ commitment to expanding our US-based manufacturing, the low CAPEX and high automation level of the Lumet systems are very attractive.”

Qcells has been building a US$2.5 billion vertically integrated manufacturing base in the US state of Georgia since Q1 2023. It is the most expansive facility planned by any silicon-based solar manufacturer on US soil to date, and in addition to its direct supply chain, Qcells has established a US solar encapsulant plant with its parent company Hanwha and signed domestic polysilicon and module recycling deals with REC Silicon and Solarcycle, respectively.

The manufacturer also has capacity across Asia.

Lumet is a subsidiary of Israeli technology company, the Landa Group. Its founder and chairman, Benny Landa, said: “We are delighted to partner with Qcells and look forward to collaboratively bringing Lumet technology to the mass production PV solar market. Not only is Qcells one of the world’s first solar pioneers, but it was also the first to reach gigawatt-scale production—and to this day, continues to be at the forefront of innovation, most recently with its introduction of LECO (Laser Enhanced Contact Optimization) technology.”