US cell and module manufacturer SEG Solar has commissioned the first phase of its newest cell manufacturing plant, in Indonesia, with an annual production capacity of 2GW.

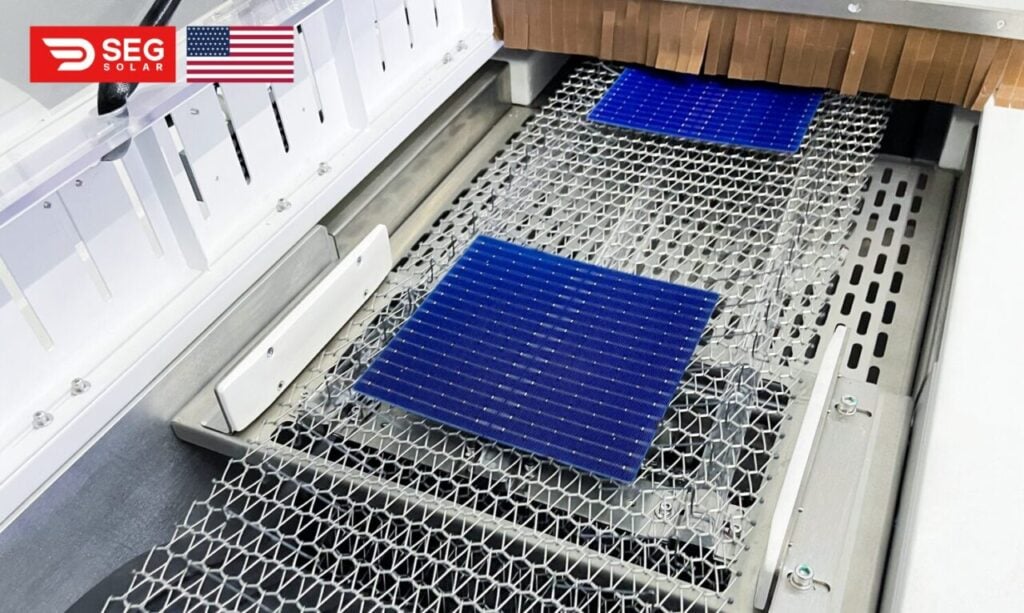

The company began construction at the facility in the Batang Regency last September, and the start of operations marks the first commercial production of SEG Solar’s “first high-efficiency n-type solar cell”. The cell boasts a conversion efficiency of 26.4% and the company says that the screen printing processes used at the facility allow cells to be produced 20% faster than the industry standard.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

This component of the facility consists of ten cell production lines, and is just the first phase to be commissioned. SEG Solar expects to expand the cell manufacturing capacity to an annual nameplate capacity of 5GW, and develop a “fully vertically integrated industrial chain”, adding silicon rods, wafers and modules to the facility’s output. The company expects to ship products from the Indonesian plant to local markets, and export products to Europe and the US.

The news is SEG Solar’s latest advancement in manufacturing, following the commissioning of a 2GW module manufacturing facility in Texas last year. The last few years have seen US manufacturers look to expand their facilities, particularly following the passage of the Inflation Reduction Act (IRA). Much of this new capacity has been in the module sector, with significantly less investment in more upstream parts of the supply chain, such as ingots, wafers and cells.

However, at last week’s Intersolar Europe event, Abigail Ross Hopper, president and CEO of the Solar Energy Industries Association (SEIA), spoke to PV Tech, and expressed confidence that the solar manufacturing industry has always been a global industry, and is one that the US ought to find its place within, rather than seek to dominate.

“We have about 50GW of modules and about 2GW of cells. It’s certainly our goal to have a robust supply chain, not just for modules but … for the balance of system,” Hopper told PV Tech. “Our position is that this is a global economy and that we will always be a part of the supply chain.”