As solar sites become more challenging, optimal land grading is becoming a critical focus for project economics. Brett Beattie of Castillo Engineering looks at some of the key areas that can make multimillion-dollar differences to project engineering costs.

Civil design rarely makes headlines in the solar industry. But for utility-scale developers and EPCs, it can make the difference between a viable project and one that stalls out on budget or timeline. Grading, in particular, can vary wildly between sites; it’s one of the largest variable costs in utility-scale construction, and one of the least standardised. A 200MW AC project’s earthwork can vary from 10,000 cubic yards (CY) to over 500,000CY, with earthwork costs ranging from US$50,000 to US$2.5 million.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

Unlike modules or trackers, there’s no catalogue for “how much dirt should be moved and where”, so faulty assumptions can send ripple effects across permitting, scheduling, equipment rentals and erosion risk. This challenge is compounded by shifting project conditions:

- Interconnection pressures are forcing developers to consider sloped or irregular sites

- Shortage of skilled labour, especially experienced utility-scale solar engineers

- Permitting requirements and timelines for erosion control and vegetation establishment

As a result, two engineering firms can provide dramatically different grading plans even for the same site, with earthwork estimates diverging by hundreds of thousands of cubic yards. This variance can result in multimillion-dollar cost differences and months of added labour – or, conversely, an underestimated opportunity for optimising costs and timelines.

Grading plays an outsized role in utility-scale solar project economics, but it’s often overlooked until costs or schedules start slipping. Traditional approaches can miss opportunities to reduce earthwork, simplify construction, and manage erosion risk. Fortunately, two recent utility-scale projects show that with the right tools and engineering practices, teams can save millions of dollars, accelerate delivery and improve long-term site performance.

What drives grading costs: volume and method

Grading decisions are often locked in early, during preliminary site layout or when the 60% civil plan set is issued for permitting. If those designs aren’t aligned with actual field conditions or constructability constraints, project teams can end up with unnecessary rework, cost overruns, or extended construction timelines. Even modest inefficiencies in earthwork design can have outsized impacts on both budget and risk in a sector that depends on tight coordination between engineering, procurement and construction.

Grading volume: US$650,000 and 20 days saved in Decatur County, GA

Volume and method are the two most significant contributors to grading costs and timelines. Volume is dictated by how much cut and fill is required to bring the site within tracker and piling tolerances. This isn’t a fixed value; for the same site, different engineering teams can produce vastly different estimates depending on design assumptions, tooling, and priorities. Even small changes in topography handling can drastically alter the volume of material moved. That’s especially true on uneven terrain, where natural slopes intersect with tracker tolerances and substation elevations.

For instance, one recent project in Decatur County, Georgia had an initial 60% civil plan set projecting a combined 320,000Cy of cut for the first two phases. A redesign, balancing sub-areas to avoid unnecessary haul distances, reduced the total to 190,000Cy. This reduction of nearly 50% led to US$650,000 in savings and shortened the grading schedule by over 20 days.

Grading method: US$950,000 and 57 days saved in Waco, TX

Grading methods matter as much as volume. Earthwork can either be internal (cut material is redistributed onsite) or external (off-site import or export of soil). The cost difference is substantial: internal movement typically costs US$4-5 per cubic yard, while external hauling can exceed US$15-30 per cubic yard, including transportation, staging and permitting costs.

Heavy equipment costs amplify these effects, since a single bulldozer costs US$4,000-5,000 per day including fuel, labour and maintenance. Haul distance, road quality and traffic restrictions, such as local daily limits, further compound cost and scheduling. As a result, a design that balances cut and fill can be exponentially more efficient than relying heavily on soil import or export.

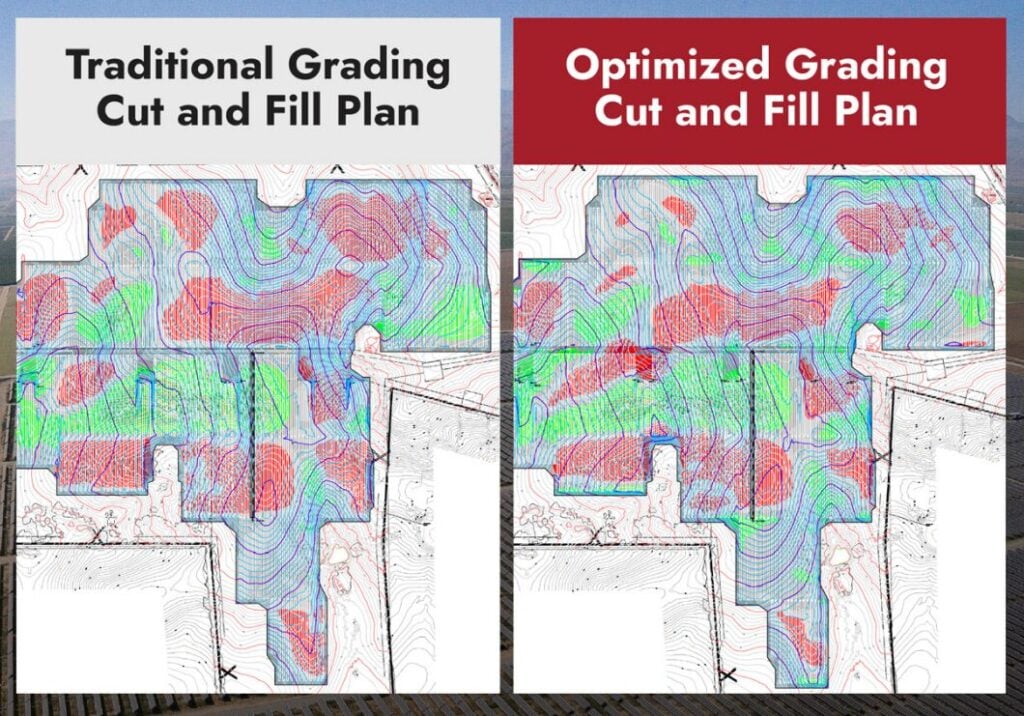

Conventional grading methods often rely on a rudimentary process of drawing straight lines between table ends in CAD or similar software, making it tedious to adjust designs for earthwork balancing. In contrast, a more advanced and systematic layout approach begins by assigning each tracker and pile a unique identifier within a logically grouped pattern.

This organised structure enables the collection of terrain data across the entire torque tube and allows each tracker to reference data from adjacent trackers. With these large, structured datasets, engineers can efficiently apply statistical analysis and optimisation algorithms to minimise earthwork. This approach achieves more refined per-tracker grading adjustments than traditional methods, while ensuring that all tracker design and client-specific requirements are met.

For one recent 545MW DC project near Waco, Texas, early civil plans estimated 650,000CY of array grading – the volume of 1.5 Walmart Supercenters. Based on internal earthwork rates of US$4-5 per

cubic yard, that figure carried an earthwork cost of over US$3 million. With typical equipment allowing only about 3,000CY of earthwork per day, this would have created a critical bottleneck of over 200 earthwork-focused workdays.

Realising this, the engineering team redesigned using the more strategic method outlined above. They applied a hierarchical identification system that categorised each tracker and pile in a clear, organised sequence. This allowed them to time-effectively smooth surface transitions, balance sub-areas to eliminate off-site haul charges and optimise the final grade for rapid pile installation. The new plan, remaining compliant with all specifications:

- Reduced the total volume by over 50%, to 193,000CY

- Eliminated off-site haul charges by balancing sub-areas

- Cut over US$950,000 from the budget

- Shortened the grading timeline by 57 days

The variability of grading costs is significant, and so is the opportunity. Creating an organised grouping scheme, labelling each tracker and foundation element with a distinct ID, and applying statistical analysis and algorithms to optimise earthwork can result in significant time and cost savings.

Plan earthwork with field execution in mind

A civil plan may satisfy tracker tolerances and structural codes but still lead to costly inefficiencies and long-term erosion if it doesn’t account for how construction crews work. This disconnect between theoretical design and practical constructability is one of the most consistent sources of budget overruns and delays in civil scope. That’s why modern civil engineering must prioritise constructability in addition to cost and compliance.

How grading design impacts vegetation establishment

The faster vegetation can be reestablished post-grading, the sooner developers can move forward with mechanical installation and permitting signoff. Accelerated earthwork enables earlier seeding, which improves erosion control compliance and site stability. Overgrading adds not only costs but also delays in seeding and vegetation establishment.

On certain sites, faster grading improves the likelihood of meeting stormwater permitting deadlines or seasonal vegetation establishment requirements. For one Georgia site, quick-turn plan adjustments to improve surface smoothness allowed crews to seed earlier and reduce exposed soil time during a critical rainy period, mitigating both risk and regulatory attention. This saved US$650,000 in costs and allowed the contractor to eliminate haul charges between sub-areas and reduce equipment downtime. With a 24 hour turnaround for design revisions (compared to the five-day industry standard), the grading team helped keep vegetation schedules and erosion mitigation measures on track.

How grading decisions reduce (or increase) stormwater costs and risk

Designs that overlook stormwater management often increase volume and pressure on drainage infrastructure. This increases the risk of long-term erosion, non-compliance with stormwater permits and delayed stabilisation efforts, particularly in regions with strict permitting timelines. In contrast, optimised grading features surface flow paths that manage stormwater runoff naturally. Taking advantage of natural site topography instead of working against it reduces earthwork, exposed soil and long-term project risk.

Even projects that avoid the above risks might still lose money due to their stormwater designs. In one recent 5.5-acre Central Texas substation project, the original design met all height, slope and drainage requirements but required over 15,000CY of import material to meet the final design elevations. Redesigning the pad with external drainage features reduced earthwork and eliminated the need for import fill, lowering costs by US$200,000 while meeting all original parameters.

Effective designs can often avoid over-grading, even in challenging terrain, by using tracking systems to optimise power production without needing perfectly flat ground. By adapting designs to the terrain instead of flattening it, trackers help projects conserve resources and minimise disruption [1]. Many major manufacturers (and some newer entrants) now offer products that support slope adaptability. These solutions vary in their degree of flexibility, so it’s key to understand each system’s design tolerances and real-world constructability. Selecting the right option will balance both engineering and installation considerations, achieving the lowest combined design and construction costs.

Designing a buildable plan

Modern earthmoving equipment is typically GPS-enabled and can adjust in real time to the engineer’s proposed surface. However, this technology has also revealed significant limitations in many current surface design standards. The cumulative effects of such adjustments can impact the final surface quality needed to install piles, so contractors prefer “buildable” plans that don’t need constant field corrections.

For instance, the Central Texas substation’s Engineer of Record analysed the final topography to match the proposed conditions with existing conditions. Designs aligned with construction best practices and workflows reduce delays caused by micro-adjustments and rework and support efficient pile installation with fewer manual corrections. Execution-focused grading supports both downstream and long-term project phases.

A field-first approach prioritises the operator and tailors designs to accommodate the large-scale machinery used in utility-scale projects. This focus significantly reduces file sizes and complexity, enables smoother operations and allows field teams to make real-time adjustments without compromising the final surface quality required for pile installation.

Tools for smarter, faster grading designs

Traditional grading design workflows often rely on static CAD files and slow iteration cycles, with calculations taking several days to complete and changes propagating manually across multiple views and datasets. This rigid process leaves little room for refinement and even less for field feedback. Combined with a chronic shortage of experienced utility-scale solar engineers, these delays can translate into extended schedules, stalled equipment and increased labour costs. To overcome this, some engineering teams invest in purpose-built tools to reflect real-world site conditions rather than theoretical topographic models.

Grading and pile optimisation software

Traditional layout methods use straight-line connections between table ends in CAD, which makes earthwork balancing difficult and time-consuming. Engineering teams can create proprietary grading and pile optimisation software for constructible, cost-effective solar earthwork plans, such as the one used to create the optimised design at the beginning of this article.

This more time-effective, structured approach assigns unique identifiers to each tracker and pile based on spatial logic, enabling full-length terrain mapping along the torque tube and data referencing between adjacent trackers. The streamlined dataset supports efficient grading optimisation through statistical models, reducing earthwork at the tracker level while meeting all technical and client requirements. Used for the Texas and Georgia utility-scale solar projects mentioned in this article, this software has resulted in grading plans that more closely reflect real-world buildability.

Engineering design optimisation software

Underlying this grading and pile optimisation capability is an internal design optimisation software that supports standardised engineering workflows across a growing portfolio. The engineering team uses this system to automate repetitive calculations, maintain consistency across phases and track performance against cost and constructability benchmarks. The software also acts as a portal that aggregates historical design inputs, ensuring that the engineering team has access to the same knowledge base and that lessons learned from one project scale effectively to the next.

Such a collective body of knowledge helps lean engineering teams, particularly those with experienced and junior utility-scale engineers, to scale both design quality and production rates. Given the limited supply of qualified civil engineers with utility-scale solar experience, this scalability is critical. By building smarter software systems around known construction pain points, engineering teams can scale their capacity to deliver timely, cost-efficient designs that work in the field.

Accurate drone surveys

Finally, drone-based site scans equipped with RTK/PPK GPS and high-resolution sensors now routinely produce vertical accuracy of 1-3cm, meeting survey-grade standards suitable for detailed grading analysis. Paired with the above grading tools, these scans allow real-time elevation anomaly detection and adjustment, significantly reducing rework by enabling more accurate and constructible designs.

The future of grading in utility-scale solar

Site constraints, skilled labour shortages and tight timelines are shaping how we must approach solar civil engineering. The most impactful civil engineering decisions go beyond numbers, taking into account what happens when boots hit the ground. As utility-scale projects grow in both ambition and complexity, grading design will play an even more central role in cost control and execution certainty.

Site selection trends are one major driver. Developers are running out of “A” land: flat, easily accessible parcels with minimal permitting friction. What’s left often includes uneven terrain, agricultural conversions, or second-use land such as former industrial sites or landfills. These parcels demand more from civil design, including tighter tolerances, better hydrological analysis, tracking systems and grading plans that flex with topographical realities rather than fight them.

Meanwhile, developers are vying for limited interconnection queue space. When construction must begin within narrow windows, engineering teams need to deliver right-first-time quality to avoid last-minute redesigns or change orders. Fortunately, advances in drone-based topographic surveys, real-time modelling and AI-informed design logic are making it possible to analyse more site variables in less time. Internally developed tools, like those used in some firms’ grading workflows, now run complex terrain calculations in hours rather than days. This allows teams to iterate quickly, test multiple approaches and hone in on constructible solutions before fieldwork begins.

As solar expands into new geographies and more demanding sites, grading is one of the last “black boxes” in project budgets where meaningful savings and certainty can still be unlocked. What was once a back-end concern is quickly becoming a front-end differentiator. The future belongs to those who treat grading not as an afterthought, but as a core part of how utility-scale solar is built.

As one civil superintendent told me, “the best grading plan is the one the crews don’t have to think about.” This alignment between paper and practice will define value-driven utility-scale solar engineering.

References

[1] Sander Varbla, Raido Puust, and Artu Ellmann, 2020, Survey Review 53 (381) pages 477-492

Author

Brett Beattie, director of civil engineering at Castillo Engineering, is a Licensed Civil PE with over a decade of engineering experience, specialising in optimising solar civil design and constructability for utility-scale projects across North America. Driven by Castillo’s mission to empower the clean energy transition through precision, transparency and technical excellence, Brett works closely with clients to ensure each project is designed to perform and last.