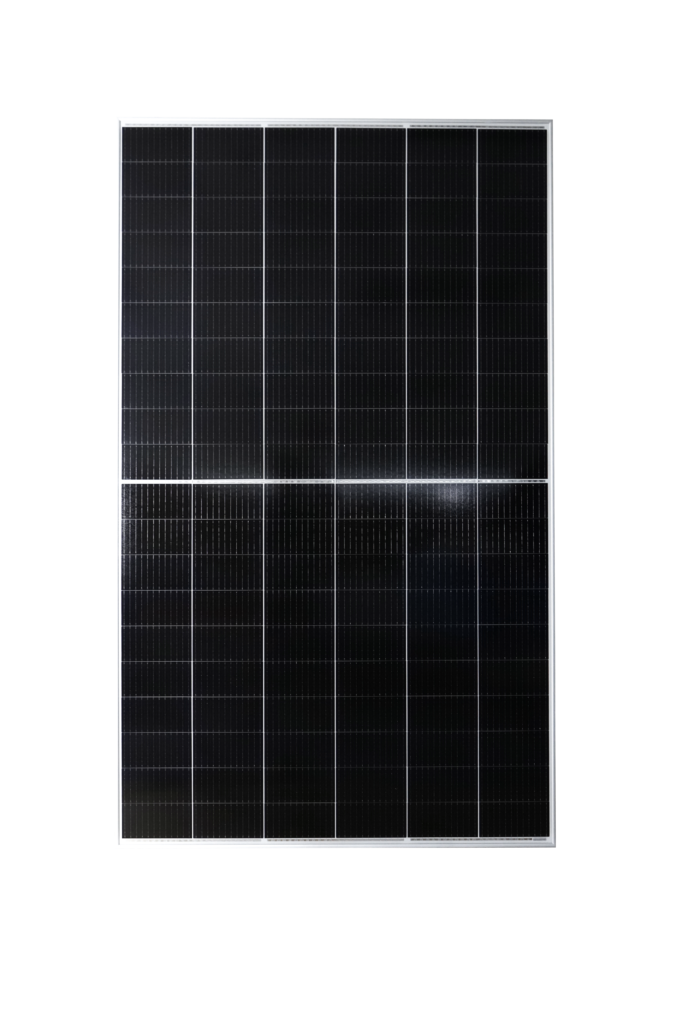

Suntech’s ‘Ultra X’ PV module series adopts large format 210mm monocrystalline wafers and 1/3 cut Passivated Emitter Rear Cell (PERC) technology, which increases the light receiving area by 80.5% compared with products of conventional formats, according to the company.

Problem

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

PV project developers and EPC’s are seeking optimisation of PV power plants that spans PV module shipping, installation, performance and high yield coupled to long lifetime expectations that can exceed 30-years.

Solution

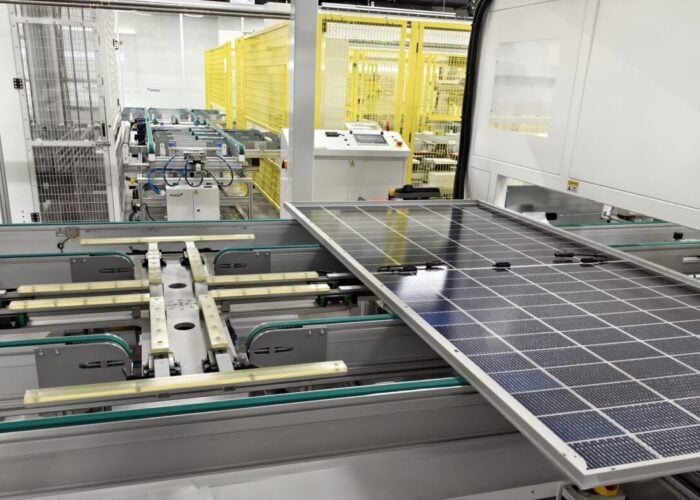

Suntech’s Ultra X product series uses a non-destructive cutting technology made it possible for effectively avoiding the damage of cutting surfaces, realising the optimal 1/3-cut design, effectively reducing the current loss and the risk of hot spots.

By virtue of the multi-busbar technology, the transverse propagation path of the current can be decreased by 50%, resistance loss can be reduced effectively, while realising the maximum power output and the reliability of the module.

Ensuring the reliability of the welding process between cells, Suntech’s upgraded high efficiency ribbon brings more second-time refection of oblique light, which increases the power generation by 1.57% when the highest power exceeds 600W+.

Fully compatible with mainstream system designs the module can match the terminals better and can save the EPC cost by more than 1.2%, save the cost of land by 4% and BOS by 2.7%, ultimately realising lower LCOE and higher return on investment of customers, according to the company.

Applications

Utility-scale PV power plants.

Platform

Suntech has a particularly optimised structure design and owns an exclusive patent. Compared to mainstream products of the same specification, the weight of the module is 26.9Kg, reduced by more than 1/5 suiting the transportation standard and reducing the labor cost of installation by 15%, according to Suntech. Module dimensions are 2172mm × 1303mm × 35 mm.

Availability

Currently available.