Solar project sites with meaningful terrain variance are becoming the norm. Nextracker’s latest innovation in single-axis tracking mitigates the cost and schedule risk associated with deploying projects on challenging terrain.

As ever-larger PV systems increase in frequency and global distribution, “easy” sites for development are fewer and farther between. Gone are the days when developers could target vast expanses of flat land as far as the eye could see. With these once-ubiquitous ideal sites for solar becoming more difficult to find, project developers are increasingly looking to site solar projects on land with undulating terrain.

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

Developing projects on sites with challenging terrain complicates project economics. Business-as-usual construction approaches require extensive cut-and-fill grading or additional foundation steel, both of which are costly. Moreover, extensive site grading invariably incurs unnecessary risks and unwelcome headaches for developers, EPCs and owners.

As a leader in the global energy transition, Nextracker is committed to eliminating project development barriers and maximising profits for long-term owners, developers, financiers, and other stakeholders. To this end, we worked in partnership with a leading EPC to develop a terrain-following single-axis tracker solution that mitigates risks associated with undulating terrain and improves project-level economics. The result of this multi-year collaboration is NX Horizon-XTR.

About NX Horizon-XTR

Sharing core technologies with NX Horizon, the XTR variant is a step forward for Nextracker’s independent-row single-axis tracker product line. A time-tested and field-proven tracker solution, NX Horizon supports more than 50GW of solar generating capacity globally, making it the number one smart tracker in the world.

The capability that makes NX Horizon-XTR unique is that it breaks free of long-standing straight-line tracker row constraints. Every other single-axis tracker product from a major manufacturer requires that the torque tube extend north and south along a single plane. In this paradigm, a laser level represents the ideal of perfection for the tracker torque tube.

This long-standing tracker architecture is well-suited for flat and relatively flat sites. It is considerably less cost-efficient at the system level for sites with challenging terrain. Project developers need more flexible tools at their disposal to open new markets or develop cost-effective sites in highly-saturated mature markets. That tool is NX Horizon-XTR.

Instead of traveling in parallel with a laser, NX Horizon-XTR’s torque tube can parallel the arc of the natural landscape. The product design permits some torque tube angle change at each foundation location. Applied cumulatively across a series of foundations, NX Horizon-XTR can effectively follow undulating terrain in a north-south direction.

NX Horizon-XTR’s slope-adaptive architecture allows the installer to use a constant pier reveal relative to the natural grade. This trait results in a terrain-following tracker installation. On sites with undulating slopes, this terrain-adaptive approach is considerably more cost-effective than business-as-usual approaches. Viewed holistically at the system level, it reduces costs for owners and developers and eliminates headaches for EPCs.

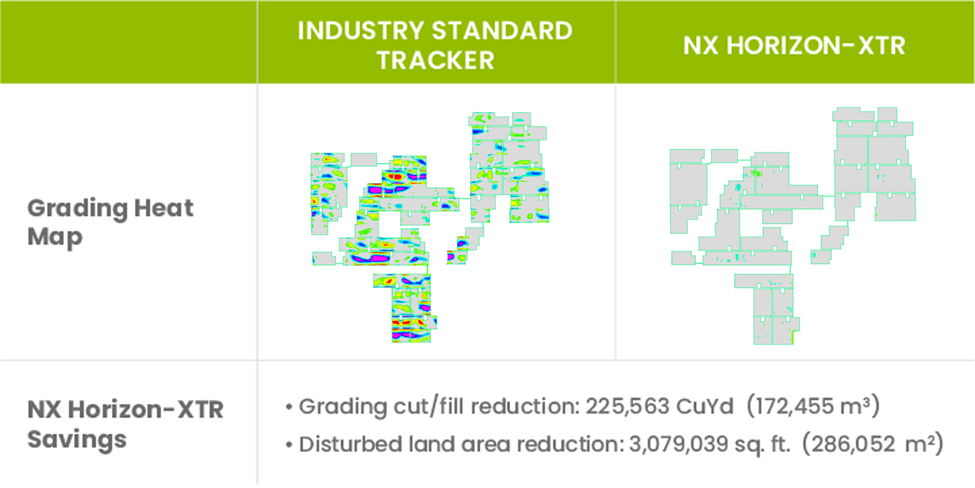

Grading and earthworks benefits

In a competitive market, developers are under constant pressure to squeeze out attractive project returns. These results are difficult to achieve on projects with undulating terrain, which represent a majority of development opportunities globally. On today’s terrain-challenged sites, grading costs to cut and fill can make or break a project.

Earthwork costs have both CapEx and OpEx implications. Therefore, any reduction in site grading has a multiplier effect for developers and long-term owners. Viewed through this lens, NX Horizon-XTR is genuinely groundbreaking.

Already deployed across a 3GW portfolio, Nextracker’s early EPC partners report that NX Horizon-XTR reduces tracker-related grading on sites with undulating terrain by 30% to 90%. On challenging sites, terrain-following designs significantly reduce first costs relative to straight-line tracker row designs.

Key savings

Earthworks savings – 1,000 to 3,000 cubic yards/MW savings

Pier savings – 5,000 to 9,000 lbs/MW savings

Reseed, top dress, environmental savings – up to 5 acres/MW impact reduction

In addition to reducing grading costs during project installation, terrain following on undulating slopes also limits opportunities for soil erosion. Extensive cut and fill activities invariably result in degraded surface conditions relative to undisturbed native soils. Over the operational life of an asset, improved soil integrity reduces operations and maintenance costs.

“In my experience, there are some things that you cannot outengineer—and well-established topsoil is one of them,” explains Nick de Vries, senior vice president of technology and asset management for Silicon Ranch. “Earthwork is especially painful as it affects solar project economics three times. First, grading a site incurs significant costs. Second, reseeding the exposed dirt is costly. Third, additional costs accrue fixing the inevitable erosion and hydrology issues that result later from a lack of well-vegetated topsoil.”

“Earthwork is especially painful because it affects solar project economics three times.”

Project risk mitigation

Site grading reductions also mitigate risks associated with a variety of unpredictable project variables—such as environmental review and grading-related change orders and schedule delays—that span the project development timeline.

On the front end of a project, grading reductions limit environmental impacts and the likelihood of community objections, expediting permit review. Permit approval is a critical step for large-scale solar projects, as failure to pass the phase gate represents an existential threat to development.

During construction, grading reductions limit the cost and schedule overrun risk associated with earthwork activities. Earthwork is never a firm-fixed-price contract. Therefore, limiting opportunities for costly change orders is fundamental to delivering a project on budget.

Similarly, limiting cut and fill activities reduces the likelihood of schedule delays. Compared to other trades and scopes, site grading is one of the most challenging in terms of schedule and budget risk. The difficulties are partly due to the sheer magnitude of today’s large-scale solar sites and partly to weather risk.

To keep projects running on schedule, it is often crucial that site grading activities occur outside of the rainy season. This timeline is difficult to ensure if permitting takes longer than expected or the extent of the site grading is more widespread than anticipated. At best, it is difficult to grade sites efficiently after a rain; in worst-case scenarios, excessive rain and flooding can halt to all earthwork activities until the ground dries out.

After the commercial operation date, terrain-following benefits accrue to the long-term owner in the form of reduced O&M costs. These project cash flow improvements reflect the fact that terrain following plays a vital role in habitat conservation and intelligent land use.

“For Silicon Ranch, high-quality solar projects and being good stewards of the land go hand in hand,” says de Vries. “Conforming to the native ground contours with NX Horizon-XTR just makes sense. It is a smarter, more streamlined way to build solar on challenging terrain.”

Pier steel savings

Increased pier length is another business-as-usual approach to developing sites with terrain variance. The benefit of this approach is that the incremental cost for additional steel is modest compared to the cut-and-fill expenses associated with extensive site grading. However, this spend-money-to-save-money approach is far from cost efficient in absolute terms.

Given the scale of today’s solar farms, buying more steel than is structurally required is a losing proposition, especially in a competitive environment. Though the incremental cost to increase the length of a single pier is not onerous in and of itself, a 100MW solar farm requires approximately 25,000 individual foundation posts. The cumulative cost associated with a universal increase in pier length is non-negligible, especially in a market characterised by inflationary commodity costs.

In the straight-line tracker paradigm, increasing pier length provides project stakeholders with a certain amount of tolerance for spanning low spots in the terrain. Installers can expose this additional steel length above grade, as needed, or bury the excess below ground. Embedding structural steel beyond the minimum-required depth not only wastes money but also increases the subsurface risks associated with pile rejection and removal.

Liberated from these cost inefficiencies, a terrain-following tracker embeds a constant amount of steel and exposes a constant amount of steel. This constant reveal allows for a foundation design that is truly right-sized relative to the site conditions. Engineering projects to these tighter design tolerances can reduce foundation pier length by as much as one meter (three feet) per pile—or 25,000 meters (75,000 feet) of pier steel per 100MW.

Energy optimisation

When implemented correctly, the net cost-benefit of terrain following is highly favourable. Though rolling with the native landscape will result in nonuniform tracker rows, Nextracker’s intelligently controlled independent-row tracking system is uniquely suited to capture the total yield of a solar asset. Combining NX Horizon-XTR with Nextracker’s TrueCapture software mitigates shade and mismatch losses while maximising energy production and economic performance.

Released by Nextracker in 2017, the TrueCapture system uses advanced sensors, weather forecasting and machine-learning technologies to continuously monitor and refine the control algorithm for each tracker row individually. In addition to increasing yield in diffuse-irradiance conditions, TrueCapture is particularly adept at mitigating shade and tracker terrain loss.

Some mismatch losses are inevitable in very large-scale solar farms. These systems cover thousands of acres, which invariably results in differences in terrain, temperatures, soiling, shade, cloud cover, and so forth. High-granularity tracking hardware coupled with high-speed, high-precision control capabilities mitigates these impacts as they happen, holistically optimising plant-level performance in the process. Best of all, new modelling tools and methodologies can capture the effect of terrain following.

“XTR has allowed us to win more projects by making us more competitive in our project bids.”

Deployed globally across more than 10GW of installed PV capacity, multiple top-tier independent engineers (IEs) have validated TrueCapture’s in-field gains and confirmed its bankability. Nextracker’s proprietary TrueSim modelling platform can estimate the yield benefit associated with TrueCapture. The list of IEs that now offer third-party TrueCapture production estimates includes Black & Veatch, DNV, ICF, Leidos, Luminate and RINA.

Making the grade

NX Horizon-XTR is a valuable addition to the industry’s collective toolkit. Civil engineers can use terrain following to retain native soils on project sites. Developers can use it to breathe new life into mothballed project sites. Owners can write terrain-following requirements into contracts, ensuring reductions in the long-term cost of ownership.

EPCs can use NX Horizon-XTR to eliminate headaches by working smarter rather than harder. Once installers place piles and brackets within the terrain-following tolerance, the subsequent alignment processes are repeatable, straightforward and well known. The construction sequence for NX Horizon-XTR is consistent with that for our standard NX Horizon solution.

Regardless of where you sit in the value chain, Nextracker has the project engineering team, design tools, technical documentation and field support to quickly get you up to speed with NX Horizon-XTR. Nextracker is not simply selling nuts and bolts and software. We also have in-house subject matter experts who guide clients along the way. While terrain-following tracking is a new discipline for many, our applications engineers have a 2GW-strong track record of proven success with NX Horizon-XTR.

Site evaluation is one of the many ways that Nextracker works closely with clients. Our standard work process includes a high-level introductory topographic study. While conducting this study, our applications engineers will proactively notify clients when site conditions favor NX Horizon-XTR. This collaboration ensures that project stakeholders are set up for success.

“XTR has allowed us to win more projects by making us more competitive in our project bids,” says Donny Gallagher, vice president of engineering at SOLV Energy. “NX Horizon-XTR’s ability to follow terrain can reduce earthwork, allowing otherwise infeasible sites to become economically viable solar projects. Less earthwork means lower upfront costs and improved scheduling. At the same time, our projects have less environmental impact. It’s a win-win scenario.”