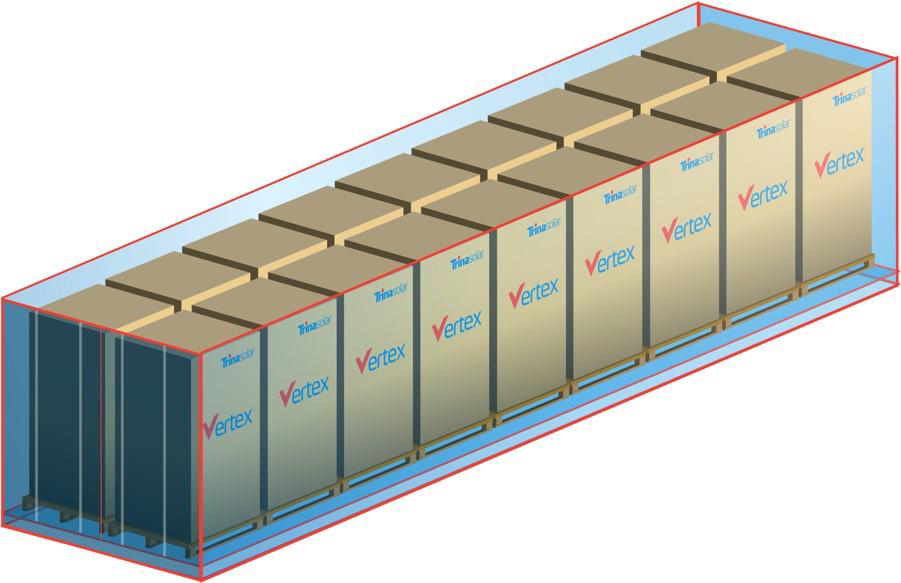

Trina Solar has revealed a new freight packing solution for its larger modules that it said will reduce the costs associated with shipping that have soared since the start of the pandemic.

The solution involves packing the modules vertically, rather than horizontally, to maximise space within the shipping container. It can be applied to its 600W+ Vertex modules, saving customers US$0.003c/W on a fully loaded container, said Trina Solar.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

Sky-high freight costs are part of the reason why the cost of modules has soared over the past year, with strong demand not being met with similar supply following the pandemic, resulting in a ten-fold increase in shipping costs in some cases.

Zhang Yingbin, Trina Solar head of product strategy and marketing, said the new solution can increase loading power by 10% and space utilisation by 5%, compared with conventional horizontal packing.

“At a time of rising shipping costs, this solution saves US$0.003c/W on maritime freight costs, assuming that a container is fully loaded with 558 modules and each module is 660W, calculated at the current mainstream price of US$10,000 per container,” said Yingbin, with Trina adding that the savings could vary with port freight price.

The vertical packing method passed the International Safe Transport Association (ISTA) 3E international packaging test and will help reduce the level of CO2 emitted from voyages, Trina Solar said.