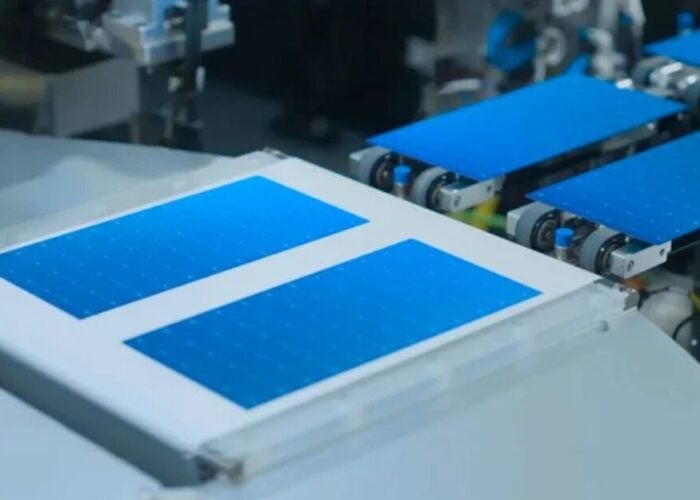

A significant leap forward in advanced screen-printing for solar cells has been touted by Applied Materials, which will be showcased at the European Photovoltaic Solar Energy Conference and Exhibition (EU PVSEC) in Hamburg, Germany from September 5-8. The new dual-lane ‘Baccini Pegaso’ screen-printer is said to enable novel, high-efficiency cell designs to be brought into mass production, effectively ‘future-proofing’ the platform due to its modular architecture. Early customer adoption includes Gintech Energy.

“The next wave of cost-per-watt reduction in the solar PV industry will be achieved through major changes in cell technology and manufacturing sophistication to simultaneously improve efficiency and factory output,” said Dr. Mark Pinto, executive vice president and general manager of Applied's Energy and Environmental Solutions Group. “We're honored that a technology leader such as Gintech Energy has chosen Applied's Baccini Pegaso technology to accelerate its cell efficiency roadmap.”

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

“The system is producing the highest efficiency cells with the lowest breaking ratio of any cell line in our facility, at high throughput and with consistently high yield,” said Dr. Wen-Whe Pan, president of Gintech Energy Corporation. “Our customers are also very pleased with the production samples we've produced using the Applied Pegaso system and we're looking forward to continuing our partnership with Applied into the future.”

Applied Materials told PV-Tech that a combination of advanced handling techniques and its new ‘Pegaso-XP’ dual print head almost eliminate wafer breakage, reducing breakage levels to below 0.1%, significantly below levels claimed by competitors. The soft handing techniques were claimed to deliver US$500,000 in wafer breakage savings annually.

The system's adaptive wafer-handling mechanism is based on planar motor technology, which offers increased speed and accuracy for the wafers being shuttled between two independent tracks. The dual print head incorporates a closed-loop optical vision metrology system that adjusts printing parameters ‘on-the-fly’ from wafer to wafer. The results are claimed to provide near micron-level accuracy and repeatability, which enables higher and repeatable cell efficiencies.

This is supported by fully integrated statistical process control (SPC) to optimise yield and cell efficiencies, Applied said.

Applied Materials is reported to be the market leader in screen printing with an estimated 75% market share.