Researchers at EPFL’s Photovoltaics Laboratory and the CSEM PV-center have reported a record tandem junction solar cell with conversion efficiencies of 25.2%, using a standard monocrystalline cell and an evaporation and spin-on process to fully coat the structure.

EPFL and CSEM claim the simple manufacturing technique could be directly integrated into existing production lines, and the cell conversion efficiency could eventually rise above 30%, according to new modelling.

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

In tandem cells, perovskite complements silicon cells as it converts blue and green light more efficiently, while silicon based cells are better at converting red and infra-red light.

“By combining the two materials, we can maximize the use of the solar spectrum and increase the amount of power generated. The calculations and work we have done show that a 30% efficiency should soon be possible,” say the study’s main authors Florent Sahli and Jérémie Werner, which was published in the technical journal, Nature.

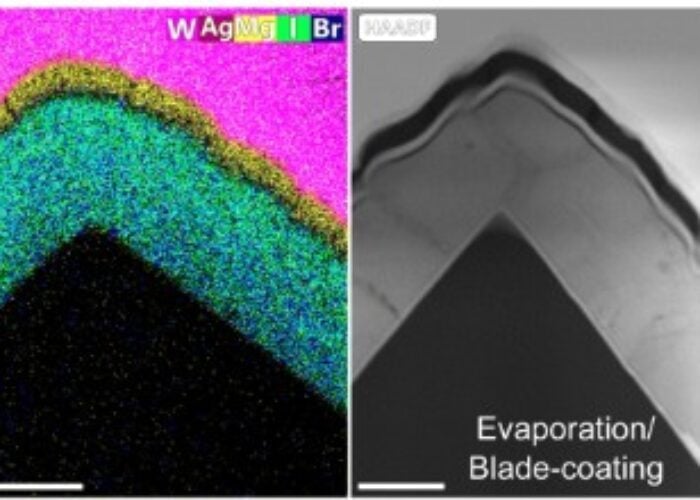

“Silicon’s surface consists of a series of pyramids measuring around 5 microns, which trap light and prevent it from being reflected. However, the surface texture makes it hard to deposit a homogeneous film of perovskite,” explains Quentin Jeangros, who co-authored the paper.

Typically, perovskite materials on their own have been deposited on small test glass plates in a liquid form, then spin coated for uniformity. However, when deposited on a conventional cell, which has a textured surface the material accumulates in the valleys between the pyramids while leaving the peaks uncovered, which lowers efficiency and creates short circuits, according to the new study.

Using an evaporation method to form an inorganic porous base layer that fully covers the pyramids was developed, enabling it to retain the liquid organic solution that is then added via spin-coating.

The substrate is heated to a relatively low temperature of 150°C to crystallize a homogeneous film of perovskite on top of the silicon pyramids, providing a uniform coating and elimination of material accumulation in the pyramid valleys.

“We are proposing to use equipment that is already in use, just adding a few specific stages. Manufacturers won’t be adopting a whole new solar technology, but simply updating the production lines they are already using for silicon-based cells,” explains Christophe Ballif, head of EPFL’s Photovoltaics Laboratory and CSEM’s PV-Center.