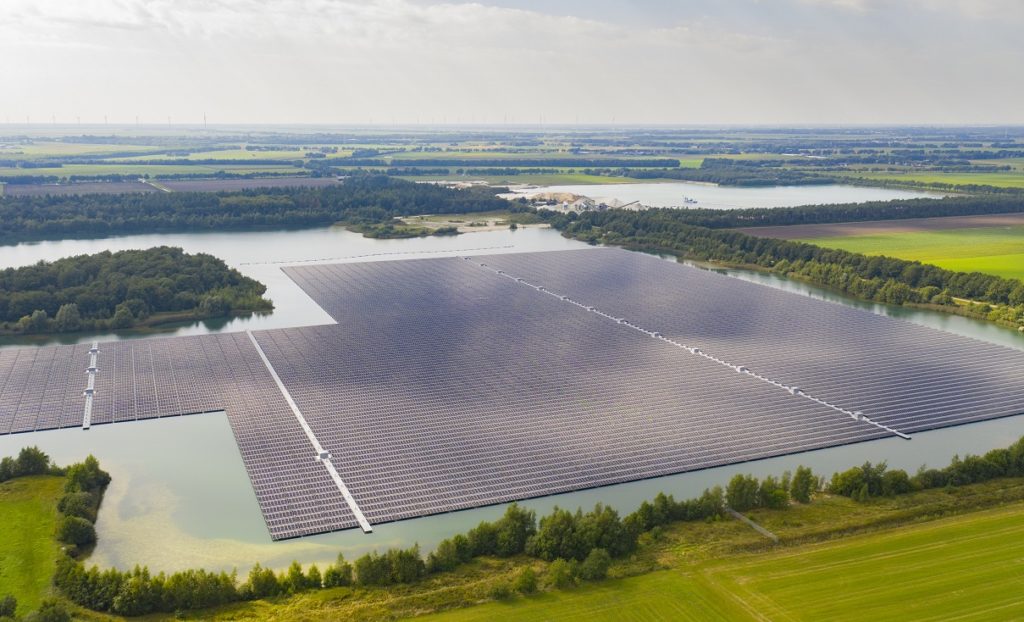

As the floating solar sector becomes more mature, larger projects are being deployed in a range of water bodies, presenting a host of construction challenges. Jonathan Tourino Jacobo talks to project developers about how the latest technology is driving growth.

Until relatively recently floating PV (FPV) was a technology barely present around the globe, only starting to boom in the past five years, mainly in Asia. But Europe has been increasing installations, factoring in the region’s necessity to accelerate renewables deployment. FPV could still be considered a nascent technology that has yet to reach its full potential, including the development of big projects (of GW-scale) and offshore FPV that is mainly in a research and development (R&D) phase.

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

In less than a decade the technology has been evolving and improving through trial and error, with the anchoring and mooring systems at the centrepiece of it. However, as with most new technologies, there is a need to create standards, to ensure the companies involved in floating solar do not wander in different directions. Setting best practice recommendations could help accelerate the improvement of projects.

DNV’s recommended practice

While only a few years ago most floating solar projects were smaller in scale, we now see a rapid increase in project sizes and GW-scale projects are expected to be feasible within a few years. “Suppliers are getting more and more professionalised. The economy, the whole supply chain, manufacturing, installation, everything is becoming more efficient, which drives cost down and makes it easier to scale to larger projects,” says Tore Hordvik, business lead of floating wind and solar at quality assurance company DNV.

The company has been working on implementing a recommended practice (DNV-RP-0584) for FPV projects, which was launched in 2021 and provides a comprehensive set of requirements, recommendations and guidelines throughout the entire lifespan of an FPV plant. “What we’ve seen is that especially technology developers, those that make the floaters but also the anchoring and mooring system, have been very active in trying to get their technology verified according to this recommended practice,” adds Hordvik.

A lack of guidelines or standards to build towards would have made it complicated for an owner, an investor, an insurance company or a government body to determine the quality of a project and what it should be, as even that was not defined, says Hordvik. Moreover, the recommended practice helped give an overview of what the standard for FPV should look like. This led developers of floaters, anchoring and mooring systems to work towards having their technology verified in accordance with DNV’s document.

It is still a work in progress and for that reason DNV recently launched two joint industry projects with more than 20 industry partners, “where the goal is to go one step further to actually define to make the design standard, not just a recommended practice”, says Hordvik, adding that this will allow projects to be certified according to DNV’s design standard.

With a technology that is still nascent, errors and failures might continue to happen, and when it does, they are a great tool to learn and improve project construction and technology. “If we are able to bring the experience from past failures back into improved procedures and guidelines, as we are doing now together with the industry, then we get something out of these incidents,” says Hordvik.

An important step to be considered while in the design phase is the operations and maintenance (O&M) of a project once completed and how workers will be able to walk around the modules while making sure there is access to the floating platform if reaching it by boat, says Hordvik, adding: “The lifecycle phases from design, to manufacture, to installation and to operation needs to go hand in hand.”

FPV becomes more complex

As the applications of mooring and anchoring for floating solar projects have become more diversified, solutions have become more complex, says Tia Qin, regional director at Sungrow FPV. “At the start of the floating solar development [five years ago], the most normal mooring or anchoring rope we would use was made of steel chain. But due to the diversity of the application scenarios we started to recommend mooring ropes with materials containing some polyester elastic ropes,” says Qin, adding that it gives better adaptability depending on the different project’s conditions.

German developer BayWa r.e. usually works with the same trusted suppliers without “locking” itself to a single provider or subcontractor for a specific item, says Michele Tagliapietra, head of product management floating PV at BayWa r.e. In the case of floating solar it works with Zimmermann PV-Stahlbau to better optimise the technology, reduce the cost, improve the stability and make it fit for harsher environments, says Tagliapietra, adding that one of the improvements the company has brought to its more recent projects are bigger boats which can host more modules.

“An example of a new development that we’re actually looking into for the projects that we’re going to install from now on is a new floating sub-structure for the transformer station. We are adopting an improved concept to optimise the cost and improve buoyancy,” adds Tagliapietra.

However, as projects are getting bigger, the technology does not necessarily need to be so different from smaller projects, but it mainly requires optimising the anchoring and mooring. “Apart from the higher loads that you can have on your mooring, the bigger the size the more you can optimise and reduce the costs,” says Tagliapietra, adding that bigger projects do not necessarily imply a longer installation time.

One of the first FPV projects that BayWa r.e. built, in Weperpolder, the Netherlands, took one month to construct and has a capacity of 2MW, while its biggest floating solar project currently, Sellingen, also in the Netherlands, took two months and has 41.4MW of installed capacity. “It’s not a linear relation between installation time and cost. For Sellingen, with a bigger installation platform, an optimised assembly process and more people involved we managed to significantly reduce the installation time and, although not in a directly proportional way, also reduce installation costs,” says Tagliapietra. He adds that money can be saved by reducing the time spent on site, the mobilisation cost and finding the right time window and weather conditions to install the project.

One aspect to take into consideration though with bigger projects is to be cautious with the anchoring and mooring loads as they will be larger and thus have larger wind areas, according to Hordvik. His solution would be to make a lot of lines instead of big anchoring and mooring systems for larger projects. “The anchoring and mooring are key when it comes to bigger structures.”

Another aspect aside from construction techniques and technology that developers are looking into is the environmental impact of floating solar projects. Due to the technology still being recent, knowledge around the effects of an FPV plant on water in the long term is still scarce and many companies are looking into it.

In the case of Portuguese utility EDP Produção it has even looked into reducing its carbon footprint at some of its latest projects in Portugal, such is the case in its 5MW FPV plant in Alqueva, by mixing the plastic used for the floaters – usually made of high-density polythene HDPE – with cork. “We reached a percentage of 30% of cork in this manufacturing process of the floaters,” says Paulo Pinto, director of innovation at EDP, adding that it is looking into implementing this use of cork and CO2 reduction in future projects.

Meanwhile, BayWa r.e. is working on studying the environmental impact of floating solar plants by performing research activities in operational projects in the Netherlands to understand how water bodies react after installing the FPV. “So far, the results are quite positive with no detectable negative impact on the water quality, water composition, water temperatures and species which are in the water,” says Tagliapietra.

Many developers asked Sungrow FPV about the potential to hybridise their projects (either with hydro, wind or energy storage) but mostly with hydropower, says Qin.

The Alqueva floating solar project built by EDP is hybrid, as it was connected to the hydro plant in the dam and also includes a battery storage of 1MW/2MWh, according to Pinto. Portugal’s latest solar auction held last year and focused on FPV had record-low negative bids posted, while showing the potential of hybridising renewable assets with different technologies.

Another common concern among developers working with Sungrow FPV is the lifetime of the floating platform and its reliability, which is due to it being a nascent technology and with the floating body being able to resist different working conditions for 25 years, according to Qin.

Unfortunately, the technological improvements made in the past years have not resulted in a decrease in the levelised cost of energy (LCOE), mainly due to the structure and the materials, says Qin.

For BayWa r.e., bigger projects, technology improvements and economies of scale on the other hand can reduce the cost per kWp of floating solar projects, adds Tagliapietra, but in the end the increased price of the materials, coupled with higher inflation, have a negative effect on overall system costs. “They are basically counteracting the technological improvements that we had made to optimise the costs and the layout.”

Impact of diverse water bodies

The way the floating structure is moored and anchored will vary depending on the water body. This is a primordial aspect to take into consideration before starting a project as most floaters are flexible in that aspect and can be used at more water bodies, according to Hordvik. “The anchoring and mooring system needs to be tailored and optimised for each project.” Both the wave height and wind speed are factors that will impact the selection of the anchoring and mooring.

According to Pinto, it is not the same to have an FPV in a dam, for example, where the water levels will fluctuate a lot more, as in sandpits. “The risk picture is much more connected to the location of your project rather than the size,” says Hordvik.

According to Tagliapietra, bathymetry – which is the measurement of water depth – is the parameter of the water body that affects the design and construction of the mooring system the most. “What really changes is how you anchor them and how you hook the mooring lines. If you have a specific type of clay, sand or rock on the water bottom it changes a lot the types of anchors you need to use,” says Tagliapietra, adding that depending on the type of anchor you have, the way you install the system can change a lot.

While working on the development of the anchoring solutions, BayWa r.e. is not only looking at the technological aspect of them but also at new installation techniques to make them more efficient as it aims to find a solution for each specific water body.

Qin says that the acidity of the water also needs to be taken into consideration, and in the case of salty water, for example, how the anti-corrosion will affect a floating platform in the next 25 years. To remedy that issue, in waters with high levels of acidity, Qin says Sungrow FPV has changed the mooring ropes from steel chain material to polymer ones.

Early days for offshore FPV

As for the next big step in terms of FPV, offshore floating solar projects are still in the R&D phase at the moment with a couple of pilot projects on water already, according to Hordvik. These are both located in the Netherlands and developed by Oceans of Energy and Solar Duck. A few more projects are in detailed design stage.

Testing and development are currently underway with numerical simulations in computers to see how reinforced the structures need to be and what kind of anchoring and mooring solutions can be used to make offshore floating solar work, added Hordvik. “What is very interesting about offshore floating solar is that a lot of the big players are really looking into this because they see the potential for co-location with offshore wind.”

Due to the distance needed between each wind turbine, that empty space could be used to add floating solar and thus increase the installed capacity of these projects. Countries like the Netherlands have started to require documenting the use of the area needed to build an offshore wind project, says Hordvik, adding “that’s partly why these kind of big offshore wind players are so interested in floating solar. Actually you significantly increase your capacity of a wind farm by putting floating solar in between, because there are so large areas.”

The other advantage of co-locating the project would help reduce the cost of having offshore FPV, by sharing the infrastructure and power offtake, according to Hordvik. Moreover, offshore FPV as a standalone at the moment would be expensive because of the necessity to make the structures much more robust than the ones found in sheltered lakes, for example. “We believe that co-location with offshore wind can be kind of our first commercial stepping stone for offshore floating solar,” said Hordvik, adding that as a standalone offshore FPV would require subsidies to be commercially viable.

If so far Asia has been the main driver of floating solar in terms of capacity installed or even in the development of the technology, Europe is setting itself ahead with offshore FPV and its R&D. For Hordvik this can be explained by the fact that most of the big offshore wind developers are located in Europe and have been key in funding the research for offshore floating solar.

As the research and potential for offshore floating continue to be improved, floating solar as a whole is poised to see accelerated growth as more countries seek to increase their renewables capacity and need to facilitate locations for the installation of solar PV. “It’s a smart technology and we have already done a lot of the initial testing. Now we are ready to scale that and improve,” says Hordvik, adding that more and more people are opening their eyes to the potential of floating solar.