Uruguay has decided to power its Antarctic base with solar power. Marcelo Mula, executive director at the installer Tecnogroup, explains the challenges as the company prepares to upscale the test array to 100kW in 2019.

Tell me about your business? How many employees, how long have you worked in solar?

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

Tecnogroup is a conglomerate of Uruguayan companies with extensive international experience in the development, procurement, construction, operation and maintenance of renewable energy plants. The group also does civil construction projects in general.

We currently employ 350 people and have several subsidiaries operating across various sectors including manufacturing, transport and logistics, electro-mechanical engineering and civil engineering.

Technova Renovables is our subsidiary dedicated to the renewable energy business and since 2012 the company has delivered turnkey projects for over 120MW in PV macro-farms (with power over 1MW) and over 10MW in about 200 PV micro-farms (power up to 500kW) in the last four years. We are also developing and executing several PV projects abroad, in countries such as the US, Chile and Argentina whilst always focusing on how we can optimize renewable energy sources and deliver long-term value and sustainability to the communities we serve.

How did you end up being selected for the Antarctica project?

The Uruguayan government is a strong advocate for the integration of renewables and following a ten-year programme to reduce its dependency on fossil fuels, 97% of the country’s electricity now comes from hydroelectric, solar, wind and biomass.

Following such success, the government was keen to extend its programme beyond Uruguay and like many other nations, the country has maintained a research base in Antarctica for over 30 years.

The Artigas base, which opened in December 1984, is home to ten research scientists and 15 crew during the summer months. The base was traditionally powered by diesel generators. Aside from the environmental impact, the logistics involved with purchasing, transporting and storing diesel in such remote and harsh conditions, made the use of fossil fuels an inefficient, dangerous and costly solution for powering these bases.

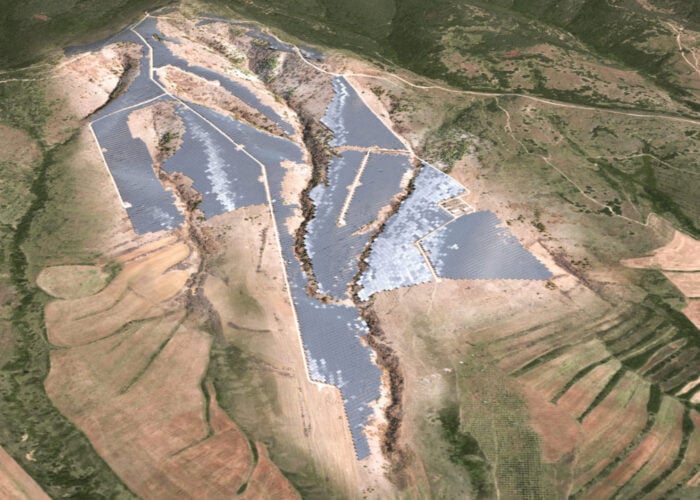

The government selected Technova Renovables, to review the potential and lead on the integration of renewables at the Artigas base. The project would need to assure the delivery of this pioneering solar installation and it would need to be designed to withstand the formidable environmental challenges of Antarctica.

Due to the importance and challenging nature of this project, it required collaboration between our partners which included the government and the energy ministry MIEM, along with the local utility company, UTE, and the Instituto Antártico Uruguayo. Collaboration was critical to managing the design and installation process within this delicate ecosystem.

What appealed to you about the opportunity?

Antarctica is one of the most inhospitable places in the world. Spanning 14,000 square kilometres and with extreme conditions including temperatures as low as -89.2°C and winds more than 200 km/h, we were interested in being able to develop, install and test the performance of PV technology in such a fragile environment and under extreme climatic conditions. At the same time, we wanted to be part of the base’s pioneering strategy and vision to increase and integrate renewables (PV, wind, biofuel) into the wider energy matrix and reduce the consumption and dependence on diesel.

Can you explain the system design to us? Why have you mounted it vertically for example?

To develop a sustainable solution for this pilot plant with 1.2kWac, the project team faced several unprecedented challenges, including biting winds of up to 200 km/h and freezing temperatures, coupled with an extreme variance in sunlight hours, with up to 16 hours in the summer to less than two hours in the winter. As a result, the installation had to be completed within a very short timeframe, before the seasons changed and the harsh winter drew in.

| Technical Summary | |

|---|---|

| Panel power (Wp) | 310 |

| Total amount of panels (units) | 4 |

| Total installed power (kWp) | 1.24 |

| Inverter nominal power (kWac) | 1.2 |

| Panel array | 4x series at 1x parallel |

To keep the project on track and meeting critical timeframe, all partners worked together to recreate the hostile Antarctic environment in a laboratory and test the solution before installation.

Polarizing temperatures and extreme variances in hours of sunlight, with up to 16 hours in the summer and only two in winter meant we had to consider how to install the PV panels. This was one of the most interesting aspects of this project as we also had to consider the optimal tilt for the location at 60°. The solar panels were vertically mounted onto the wall of an existing machine room, with a 90° tilt and N orientation and at a considerable height so they could overcome the heavy snow accumulation and wind present at the site.

What modules and inverters have you selected and why did you choose them? How did you test them?

We used BYD310P6C-36 (Pmax 310W) solar panels integrated with the UNO-DM-1.2-TL-PLUS (1.2kW at 230VAC 1ph) ABB inverter. The weather station also features a VSN700-03 datalogger, UNO-DM-COM KIT communication board, a VSN800-14 weather station, RCD and MC4-Evo2 connectors, as well as the main CB. We usually work with these components as they have proven to be reliable and well supported by the manufacturer ABB.

The flexible plug-and-play capabilities of the UNO-DM-PLUS inverter, coupled with remote monitoring through ABB's Aurora Vision plant management platform, meant that we would not only be able to complete the 1.2kW installation within a three-day time-frame, but would also be able to remotely monitor its performance while gathering data on weather patterns that will better inform larger scale PV installations of the future.

Based on the remote monitoring capabilities required by the ABB Aurora platform, another element we had to consider was the availability of an internet connection. Ensuring a reliable internet connection was provided thanks to the robust satellite connections onsite.

What adjustments have you made to make the system survive the Antarctic climate?

The support structure was made with aluminum sliding rails with an anti-vibration system fixed to the wall of an existing machine room to avoid problems related with the heavy snow and wind which are typical in the location. The inverter was installed inside the machine room.

What shape of demand profile do you expect in the summer and winter?

The demand profile is mainly related to the amount of people present at the base. The maximum demand is reached during summertime, when many scientific missions are carried out. Over 40 people can be expected to be on site at any one time. This demand is significantly reduced during winter, where only seven or eight people stay at the base.

How will the annual yield perform at such a latitude?

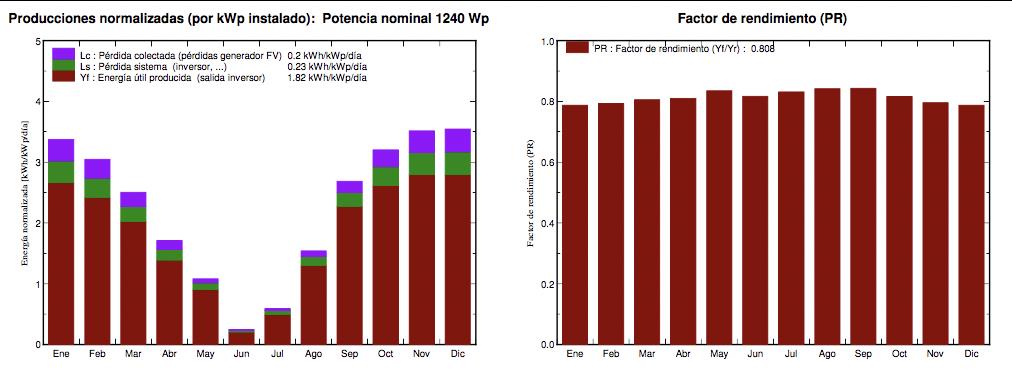

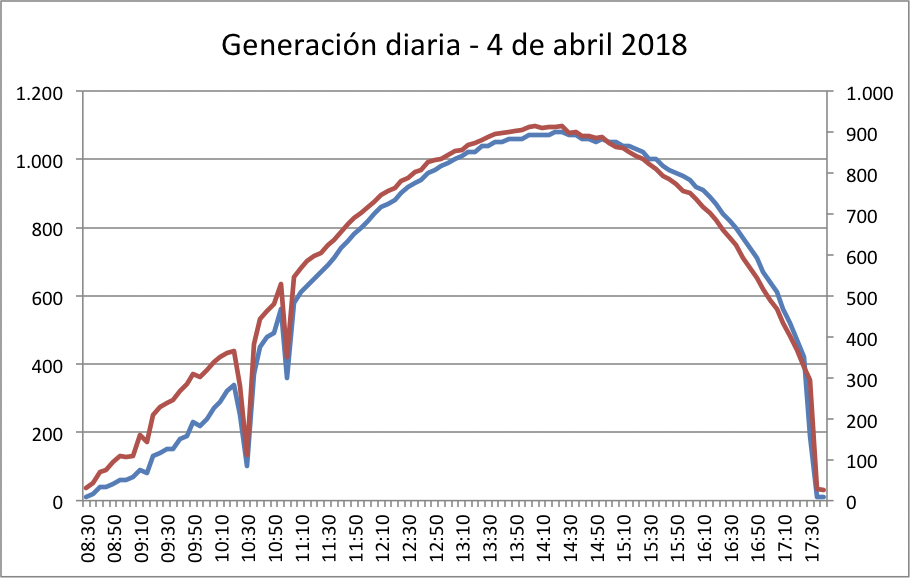

The plant yield is shown in the first graph attached below. The performance ratio of the plant is shown in the second graph. As you can see the curve is very flat through the whole year, with an average of 80%.

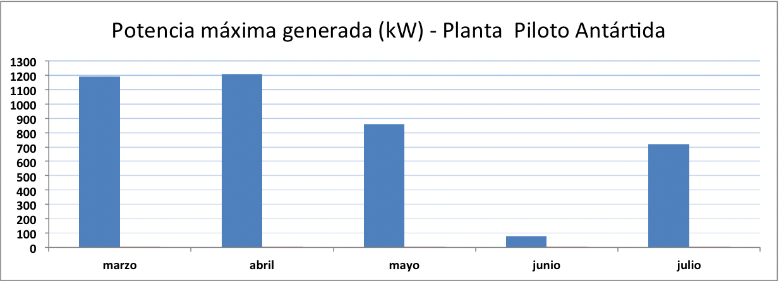

Since the plant’s commissioning back in March 2018, the following maximum power generation levels have been achieved:

The actual optimum tilt in this location is 60° and orientation should be N. However, it was decided to install them to the external wall of the machine room to withstand the high winds. The daily generation curve shows that the plant is performing as expected in this installation condition.

What is the O&M plan for the system? Will you use specific tools?

The operation and maintenance of the plant is the responsibility of the UTE personnel present on site who also take care of all energy requirements. The remote monitoring capabilities provided by ABB’s Aurora Vision web portal, provides deep analysis on how the plant is performing and allows for proactive troubleshooting which can also be done remotely from Uruguay.

Solar irradiation usually means the technology makes less sense towards the poles, now that costs have fallen and performance has improved, how valuable could solar be to helping off-grid communities in remote Arctic and Antarctic locations?

The potential of PV in co-location with other renewables such as wind or biofuel along with other energy storage systems such as battery or mechanical, could mean that remote locations or off-grid communities could have reliable electric supply throughout the day, 24/7 and 365 days per year, and at a reasonable cost.

In our case, this installation will help the Artigas Base to not only reduce the environmental impact of its operations but also reduce OPEX costs, by improving purchasing and logistics, which are often complex and costly in such harsh conditions.

Early indications from the pilot project are already showing encouraging results and the next step is to install a 100kW plant in 2019. While only a first step, the outcome was a testament to the partnership working between all the companies. Soon, Uruguay could be the first country in Antarctica to be almost independent from fossil fuels.