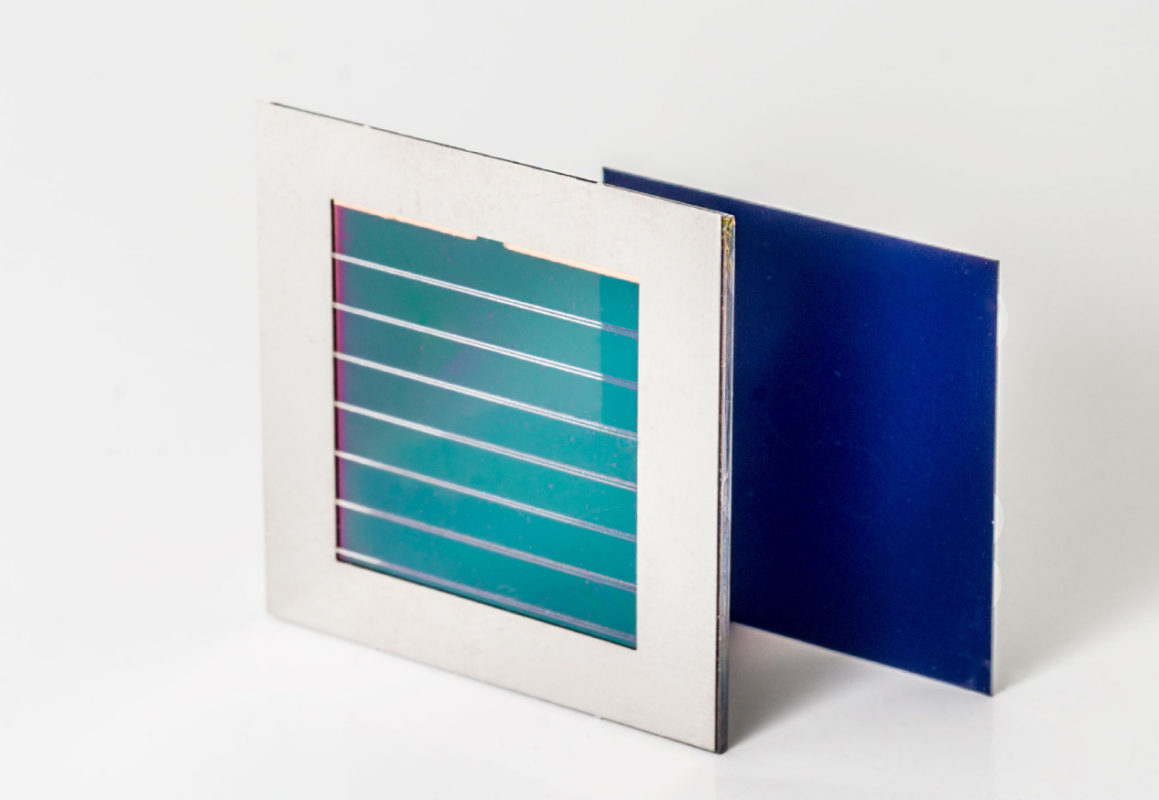

Nanoelectronics research centre imec has taken a perovskite/silicon tandem mini-module-on-cell stack to a record 23.9% conversion efficiency, significantly exceeding its 20.2% efficiency figures reported in 2016.

In 2016, imec used a semi-transparent perovskite mini-module, which was developed in collaboration with Solliance that was stacked on top of a high-efficiency interdigitated back-contact (IBC) crystalline silicon solar cell in a four-terminal tandem configuration with an aperture area of 4cm2 to produce 20.2% conversion efficiency.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

Several new engineering tricks were used to boost the tandem mini-module to 23.9% conversion efficiencies, which included a better engineered perovskite material (CsFAPbIBr), an anti-reflection texturing process on the surface of the module as well as depositing a higher (air, 1.44) refractive index matching liquid between the perovskite module and IBC silicon cell.

“Two innovations are key to this achievement,” explained Tom Aernouts, group leader for thin-film photovoltaics at imec and perovskite PV program manager at Solliance. “First, a different perovskite material (CsFAPbIBr) was used, largely improving the stability and conversion efficiency of the 4cm² semi-transparent perovskite module to 15.3 percent. Second, the architecture of the stack was optimized for minimal optical losses by adding an anti-reflection texture on top of the module and a refractive index matching liquid between the perovskite module and the Si solar cell.”

Imec noted that the four-terminal tandem mini-module had matched aperture areas as large as 4cm2 for the perovskite module and the Si solar cell.

“Having matched areas of this size makes the fabrication technology more attractive to the solar cell industry,” added Aernouts. “For reference, we have also fabricated a stack of a small perovskite cell (0.13cm2) on top of an IBC c-Si cell (4cm2). In this configuration, the power conversion efficiency of the small semi-transparent perovskite cell is 16.7 percent, outperforming the larger 4cm2 perovskite module due to better perovskite layer properties. Although less attractive from an industrial point of view, the overall power conversion efficiency of this cell-on-cell stack is as high as 25.3 percent.”

Imec believes that by stacking the perovskite solar cells or modules on top of silicon solar cells is a key route to eventual commercialisation of perovskite material options with power conversion efficiencies potentially above 30% with the opportunity to be relatively low cost for tandem cell roadmaps.