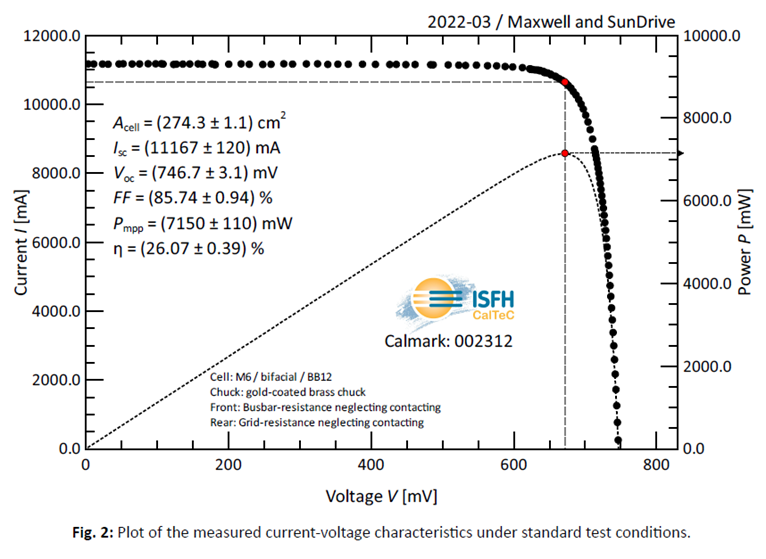

Heterojunction (HJT) equipment manufacturer Maxwell Technologies and Australian solar technology start-up SunDrive have laid claim to a breakthrough in mass production HJT technology after recording a conversion efficiency of 26.07% with a commercial-size solar PV cell.

The companies said the result “demonstrates the future potential for HJT solar cell efficiencies exceeding 26% in mass production”.

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

Testing a M6 (274.3cm²) cell, the trial has been officially verified by German’s Institute for Solar Energy Research (ISFH).

The two companies recorded a conversion efficiency of 25.54% in September last year and 25.05% during testing in May. They said the latest result was down to improvements in open-circuit voltage (Voc), short circuit current (Isc) and fill factor (FF).

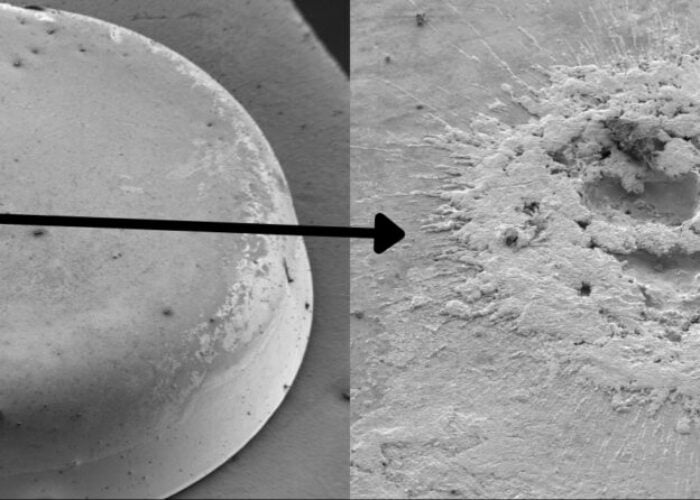

They adopted Maxwell’s latest generation chemical vapor deposition (CVD) equipment for microcrystalline silicon layer deposition and a physical vapor deposition (PVD) coating process to create high mobility transparent conducting oxide (TCO) layers.

Maxwell said it believes HJT will be the “key technology for the sustainable future of the PV industry” and that the mass production efficiency of HJT cells could be improved further through an iterative upgrading process.

The two parties said they would continue to collaborate on exploring more solutions for the HJT industry in the fields of microcrystalline, TCO, metallisation and module interconnection.