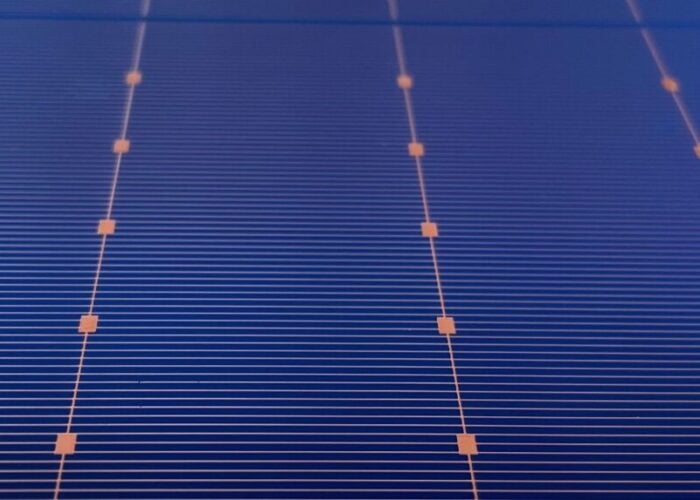

Heraeus Photovoltaics has launched a new PERC (Passivated Emitter Rear Contact) metallization paste. The SOL9631 front-side paste has a new and unique glass chemistry combined with a new organic vehicle system. Due to a denser microstructure it is tailored for ultra-fine line printability for screen printing.

Problem

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

The increased migration to PERC solar cells to boost conversion efficiencies has highlighted lower process (firing) temperatures are required, while providing excellent adhesion. PERC cells also need to have limited impact from LID (Light Induced Degradation).

Solution

The SOL9631 Series has been developed based on new glass chemistry, combined with the latest breakthrough in organic vehicle system for ultra-fine-line printing. As confirmed by customers SOL9631 Series has improved LID performance and improved reliability for both cells and modules. SOL9631B has a wide firing window and can be fired at low temperatures, which makes the paste specifically suitable for the application on PERC solar cells. At the same time, the paste shows excellent performance at regular firing temperatures. The paste is specifically strong in the feature of adhesion. The SOL9631 series is tailored for Ultra-fine line printability for screen printing. It supports a finger geometry that can print defect-free through a less than 30μm screen opening in high throughput mass production, resulting in an efficiency gain through reduced optical shading and less contact area.

Applications

Ultra-fine line printability for screen printing of PERC solar cells and BSF cells.

Platform

The SOL9631 series features a unique glass chemistry that enables the tolerance of low firing temperatures. After low temperature firing the microstructure of the fired finger shows a much more densified structure including the Ag-Silicon interface, enhancing adhesion, grid resistivity and solderability.

Availability

May 2016 onwards.