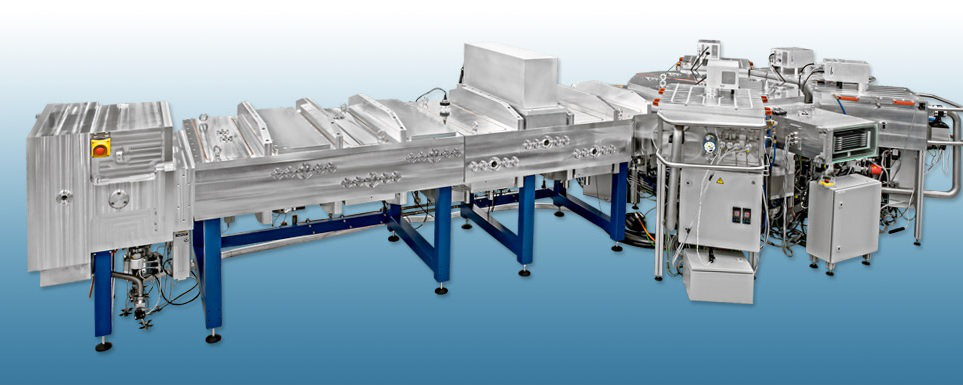

INDEOtec’s Octopus II PECVD system has proven capabilities in the formation of heterojunction solar cells that enables top and bottom side thin film substrate deposition without the need of substrate flipping and vacuum breakage. The proprietary reactor design and a unique electrode arrangement allow low plasma ignition levels and low ion bombardments, which result in superior film thickness uniformity and excellent passivation levels.

Problem

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

The ability to provide double-sided PECVD deposition of intrinsic and p/n doped a-Si:H layers for heterojunction PV cell devices has the potential to both lower processing costs and provide superior film thickness uniformity and passivation levels that provide higher overall cell conversion efficiencies.

Solution

The OCTOPUS II system generation deploys several new PECVD reactor elements for RF and VHF plasma deposition such as the Mirror reactor concept, which enables the top and bottom side thin film substrate deposition without the need of substrate flipping and vacuum breakage. The proprietary reactor design and a unique electrode arrangement allow low plasma ignition levels and low ion bombardments, which result in superior film thickness uniformity and excellent passivation levels. Another benefit is the capability of creating various, chemically homogeneous thickness profiles across the substrate surface.

Applications

The system can deposit semi-conducting layers: a-Si:H, µc-Si:H, nc-Si:H, SiGe:H etc. Multiple layers (layer stacks) may also be deposited in one reactor without any interruption of the vacuum.

Platform

The OCTOPUS platform the company offers a modular and fully automated cluster deposition system for the deposition of various singular or multiple stacks of thin films by means of PECVD or PVD. The OCTOPUS system significantly reduces the substrate handling and avoids vacuum breakage between top and bottom side deposition cycles.

Availability

Currently available.