Heraeus unveils new PERC metallization pastes

Metallization paste producer Heraeus Photovoltaics has launched a new generation of high-efficiency silver front-side metallization paste at PV Taiwan in Taipei.

Andreas Liebheit, president of Heraeus, told PV Tech that the new SOL9641A series paste raises the conversion efficiency of solar cells by 0.1%.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

Liebheit added: “We are ambitious to increase the cell capacity through our paste every half year by 0.1% and we managed that quite sustainably recently.

“[The paste] also supports PERC and fine line printing, which helps to save paste and costs. The adhesion has doubled from the last paste generation so it will be safer in terms of quality promises.

“It has a wide process window so it allows us to process into the paste within a tolerance of 50°C, which was before typically 15-20°C. This makes the paste very robust if you have fluctuations in your firing temperature. It still provides good output.”

The product was designed in Philadelphia at Heraeus’ main R&D hub and the firm is now sending it out to various regions including Taiwan where it has local R&D sources for the last step of customisation.

Liebheit said: “Every customer gets different versions of that product. We optimise towards their process requirements.”

Heraeus claims that the paste has improved adhesion for PERC cells to help optimisation of busbar design for better electrical performance and cost reduction, especially on black-silicon texturings.

The paste is also compatible for both multi and mono crystalline wafers. It has ultra-fine line screen printing capabilities, which makes it suitable for the latest screen technology with narrower finger opening, high mesh and thinner wire as well as for knot-free screens.

Liebheit said Taiwan remains a critical market force for solar energy development and will play an important role when the market comes back into an upswing mode – adding: “The PV markets across the Taiwan straits are strongly interlinked across the Asia-Pacific region. Taiwan companies have established R&D and production sites in mainland China, so it makes strong strategic sense for Heraeus to have a strong presence in both regions. It allows us to simultaneously work with cell and module manufacturers in both markets to help them deliver even higher-performing cell technologies.”

Brave C&H Supply shows new screens for solar cells

Taiwan-based printing screen maker Brave C&H Supply has launched a new series of high performance screens for solar cells at this week’s PV Taiwan exhibition.

Morice Lin, executive vice president of Brave C&H Supply, said the C Series reforms the traditional screen production concept in order to improve cell efficiency by 0.1-0.15% as it has a mesh angle of 0 degrees.

The new series requires less paste and has a higher throughput than previous products.

Brave's other S Series combines new mesh counts with the latest emulsion T75000 to improve printing resolution.

Brave has entered markets in China, the US and Europe and has piloted the new C series with a customer in Taiwan.

Hamak reveals off-grid converter and utility-scale inverter

Taiwan-based EPC firm Hamak Technology has unveiled a central inverter as well as a residential and commercial-scale batteryless hybrid system at PV Taiwan.

Wayne Liang, sales manager, Hamak Technology, said that in the coming two years the utility-scale sector will take off in Taiwan and for that reason the firm will soon launch a utility-scale central inverter, the PV Combiner Box. This will be a DC 1000V system for large-scale plants.

The firm has also released a batteryless off-grid converter, the HA-HSS3000-DC, which is for the residential and commercial market. The converter is used for self-consumption of solar energy and is particularly suitable for industrial cooling fans, pumping motors and DC motors.

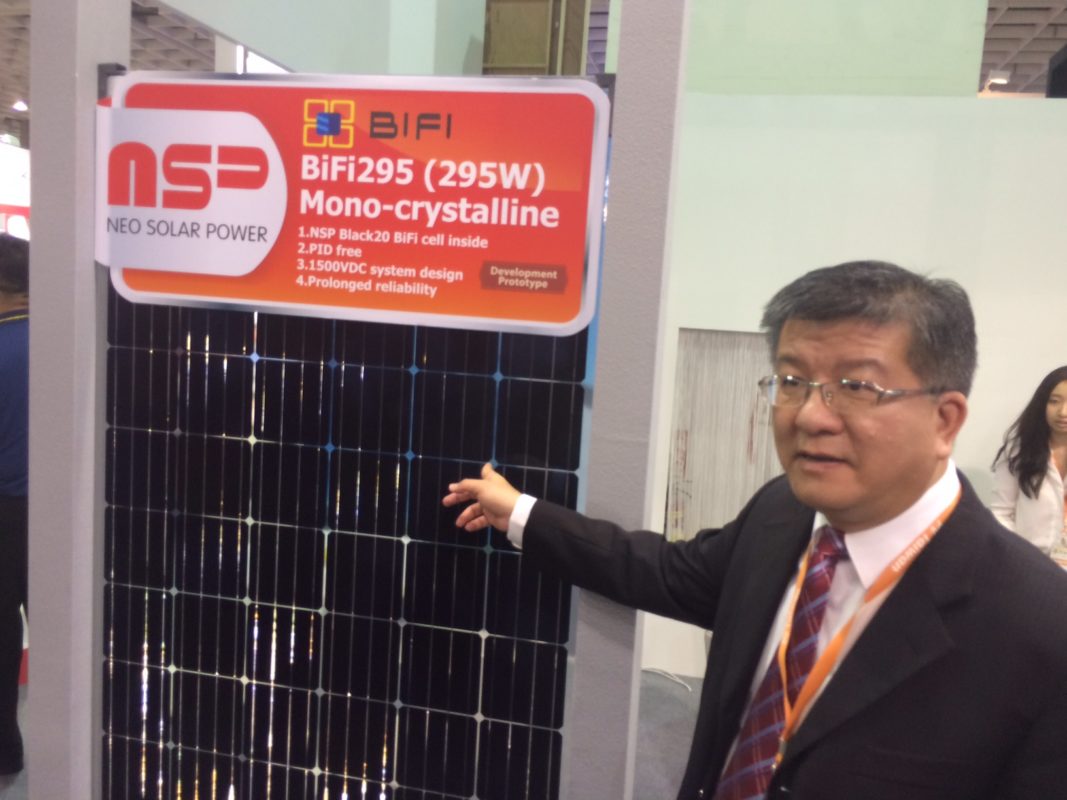

NSP unveils double glass and heterojunction modules

Neo Solar Power has unveiled a double glass module as well as a heterojunction module at the PV Taiwan exhibition.

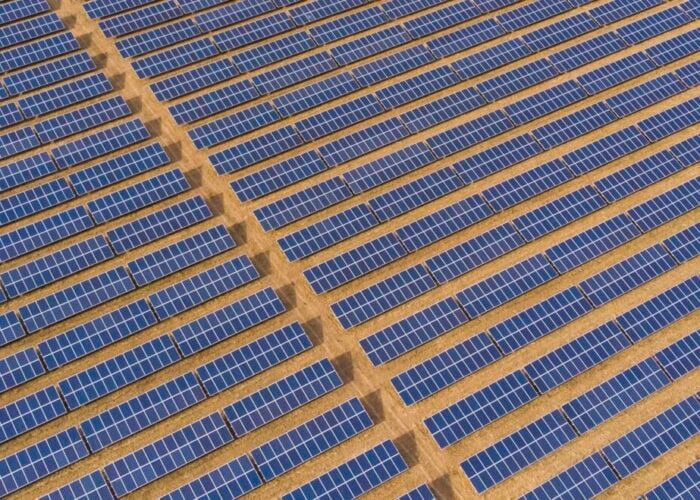

Alex Wen, senior vice president, NSP, told PV Tech that as the Taiwanese government plans to release new land for solar PV development in special areas, much of which will be close to the sea, a specific kind of module is necessary to cope with the conditions.

As a result, NSP is launching a double-glass offering, the BiFi295 mono-crystalline module, which is suitable for the desert, water areas or close to the ocean. NSP kept the module light using ultra-thin glass and offers a 30-year guarantee.

The second new product, the Hello325, involves heterojunction technology and the company plans to have a production line in Q1 or Q2 next year. They will be 325W and will use NSP Hello22 cells.

Wen said: “So from Q2 next year, we can shift a module with a very high power with new technology to all my customers in Europe and in Taiwan.”

3D-Micromac launches PERC laser product

Laser micromachining systems specialist 3D-Micromac has launched a laser system for processing mono and polycrystalline solar cells at PV Taiwan.

P-J Broodbakker, sales manager Asia, 3D-Micromac told PV Tech that the MicroCELL OTF is used to open the backside of wafers for pasting and the product aims to increase the efficiency of PERC cells. The on-the-fly laser processing product offers contactless wafer handling and an uptime of more than 97%. It also has a throughput of more than 3,800wph with single lane processing.

3D-Micromac’s other offering, the ‘microCELL’ TLS has already been launched. It is a laser system for separation of standard silicon solar cells into half cells. Broodbakker said the TLS aims to prevent micro cracks in cells when cutting them.

By using thermal laser separation technology, the process puts no mechanical stress on the wafer and avoids wafers breaking when exposed to extreme thermal changes, Broodbakker claimed.

Darfon launches next generation micro inverter

Solar solutions provider Darfon has launched a third generation micro inverter for both residential and commercial applications at PV Taiwan.

The G320 micro inverter can connect to 350W solar panel modules and is compatible with 60 and 72-cell modules

It comes in four voltage options so it can be installed in both residential and commercial applications, with 208, 240, 277 VAC available.

The product is aimed at small power units for flexibility and low budgets, but is also expandable to larger system capacities.

Robert Yuan, vice president of Darfon Electronics Group told PV Tech that most competitor products only go up to 280W output, but the G320 has an output of up to 300W.