Chinese researchers have developed a new process they claim boosts the efficiency and bifacial performance of tunnel oxide passivating contact (TOPCon) solar cells while reducing silver consumption.

TOPCon cell technology has established a dominant market position in recent years, but the team from the Ningbo Institute of Materials Technology and Engineering (NIMTE) at the Chinese Academy of Sciences identified a “significant challenge” in balancing efficiency, manufacturing cost and bifacial energy yield in the technology.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

“Overcoming this efficiency-cost-bifaciality trilemma is crucial for enhancing the competitiveness and accelerating the deployment of TOPCon technology,” they said.

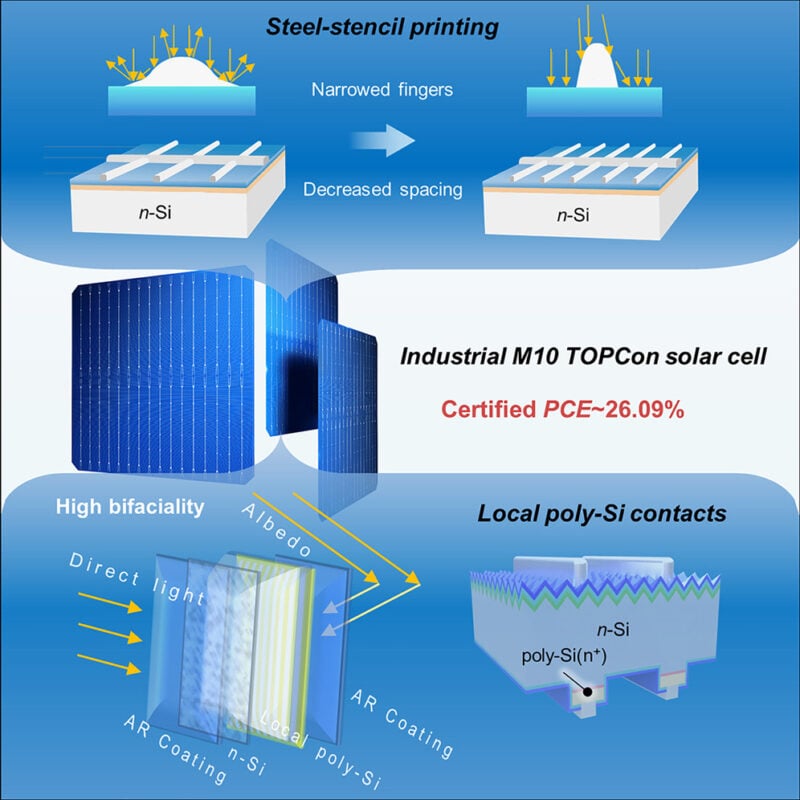

The team, led by NIMTE’s Professor Ye Jichun, developed a process that integrates a precision steel-stencil printing technology and a local polysilicon contact design to achieve a certified efficiency of 26.09% on industrial-grade M10 silicon wafers.

Additionally, the researchers noted that the transition from conventional screen printing to steel-stencil printing enabled the use of narrow fingers, resulting in “substantial” savings in silver consumption. Reducing silver in PV cells is seen as a key area for future cost savings.

Meanwhile, they said the laser-patterned localised polysilicon contact design improved cell bifaciliatiy by optimising the trade-off between carrier transport and parasitic absorption. A bifaciliaty level of ~90% was reported, a level they said was “beneficial for practical energy yield”.

Concluding, the researchers noted: “By demonstrating a viable path to simultaneously enhance efficiency, lower silver consumption, and unlock bifacial gains, this work provides a scalable blueprint for photovoltaic manufacturing, strengthening the position of TOPCon technology for terawatt-scale sustainable energy deployment.”

The process is presented in a paper published in the journal Joule.