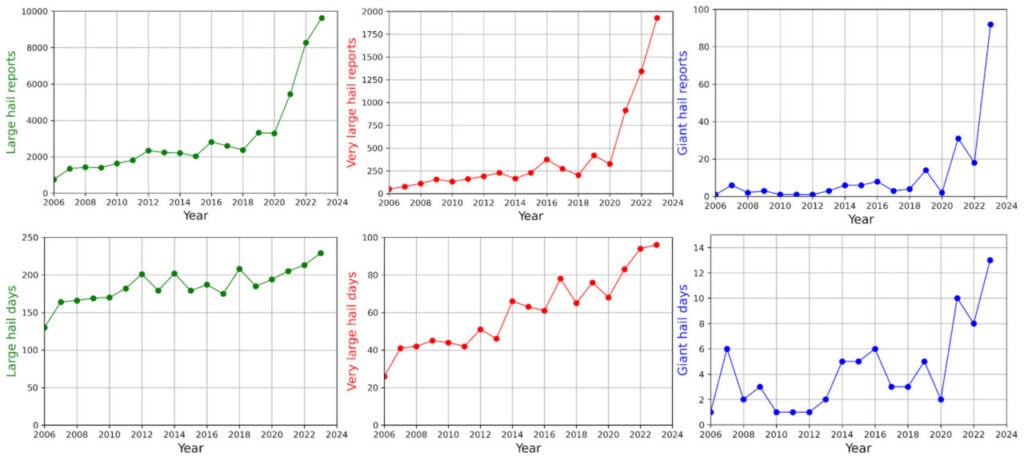

The frequency and intensity of hailstorms are projected to rise globally, with larger hailstones becoming increasingly common. In regions like Australia and Europe, both the frequency and severity of hail are expected to increase. In contrast, North America may see fewer hailstorms, though the size of hailstones is likely to grow. Even in areas where hail is typically rare, the likelihood of such events has risen significantly. Simultaneously, the frequency of other extreme weather events, such as Category 5 hurricanes and heavy snowstorms, is increasing. This trend has redirected the industry’s focus towards the enduring reliability of PV modules.

Current PV systems are vulnerable to hail damage for multiple reasons. Such extreme weather events could drastically decrease module efficiency or increase maintenance expenses, leading to a a higher levelised cost of electricity. Manufacturers and stakeholders are currently putting more effort into researching innovative technologies and solutions to mitigate the risks brought by extreme weather.

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

Tempered glass or heat strengthened glass? Insights from glass treatment

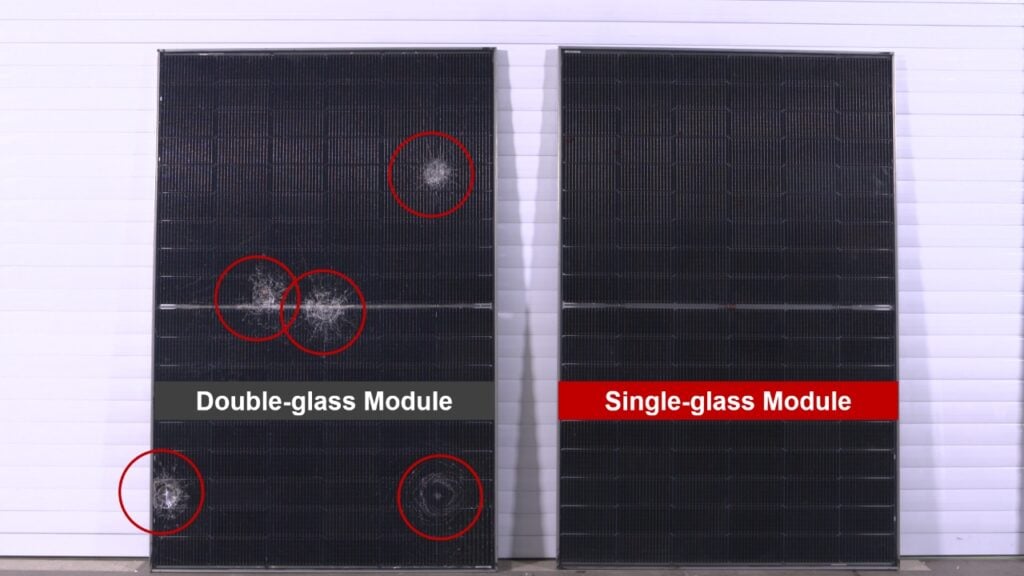

Among the current module products on the market, only single-glass modules are equipped with tempered glass. The choice of front and shear materials is critical in determining the module’s ability to withstand hail impacts. Over the past decade, the PV industry has experienced a great revolution. A diverse array of components has been applied across a spectrum of modules, each claiming enhanced efficiency and reliability.

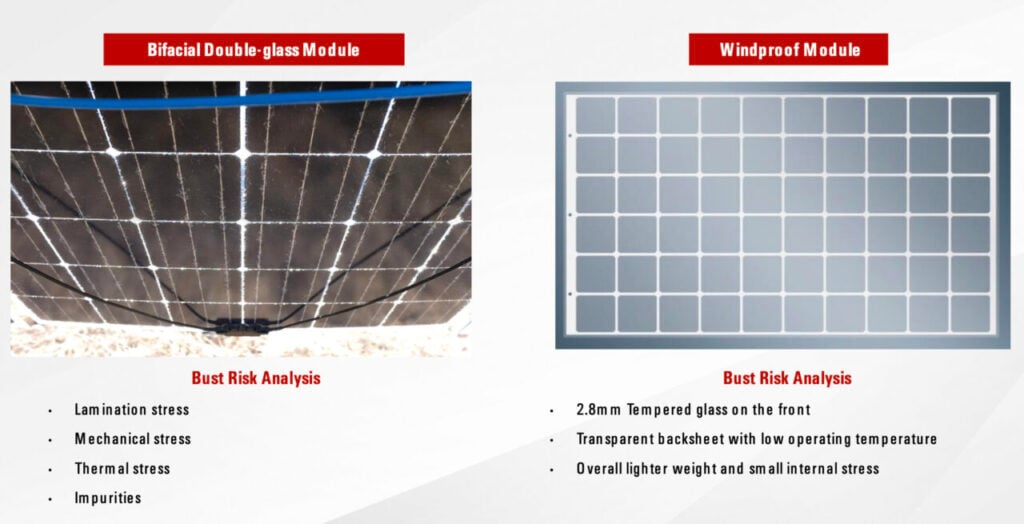

There has been a noteable shift from the initial single-facial single-glass modules to bifacial double-glass modules. Double-glass modules, with their performance in the face of salt mist, high temperatures and high humidity, have won the market’s favour. However, this trend is not without its risks. The concurrent trend towards higher power output and larger module sizes has introduced new concerns that demand urgent attention, with the risk of glass cracking and bursting being particularly prominent.

As the industry moves towards thinner glasses to meet weight specifications and cost reduction goals, the challenge lies in maintaining the necessary impact resistance. For instance, the transition from 3.2mm to 2.8mm for single-glass modules and 2mm for double-glass modules, and even to 1.6mm, necessitates a careful consideration of the glass treatment. Thinner glass, especially below 2mm, is typically heat-strengthened, which does not provide the same level of impact resistance as tempered glass. Tempered glass, with its higher surface compressive stress of ≥90MPa, offers a significantly stronger resistance to impacts compared to heat-strengthened glass, which has a surface compressive stress ranging from 24MPa to 69MPa.

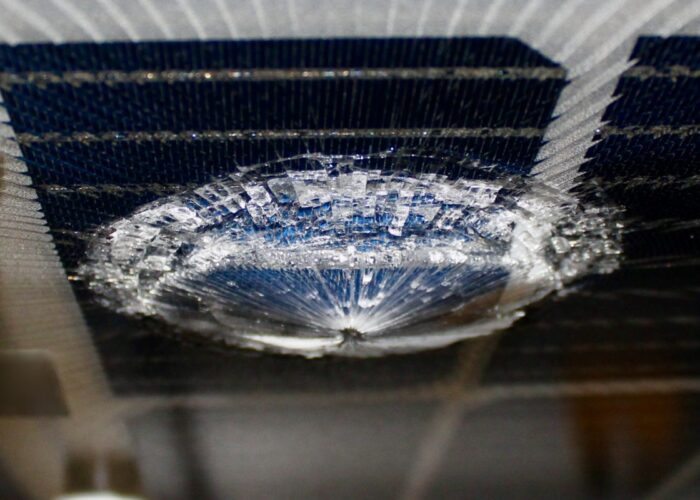

This difference in strength is crucial for the front glass of PV modules, as it is the first line of defence against hailstones. The tempered glass’s ability to break into small, less harmful pieces makes it a safer option in the event of an impact, whereas heat-strengthened glass, which breaks into larger fragments, poses a higher risk of damage to the module and potential injury during maintenance. Therefore, a single-glass module with thicker tempered front glass is more reliable when hailstorms happen.

Considering the challenges of thinning PV glass and its effect on module strength, one might wonder why not produce 2.0mm glass using a fully tempered process. The issue is that as glass becomes thinner, the tempering process becomes more difficult; achieving the necessary flatness is challenging, leading to low yield rates and increased production costs. Moreover, using a combination of tempered glass on the front and heat-strengthened glass on the back is economically unfeasible. Such a combination would not only drive up costs but also add significant weight to the modules, making them less suitable for installation and transportation.

The only feasible way for tempered glass to be widely used in solar modules is its application in single-glass modules.

Long-term value to be held as principle

The prevailing benchmark for hail resistance, which stipulates that solar modules must be capable of withstanding impacts from hailstones up to 35mm in diameter, may fall short in areas frequently subjected to larger hailstones. In the past 12 months, several manufacturers declared that their modules had passed the hail resistance test with the hailstone diameter over 40mm, such as the Seraphim 210 module, the Jolywood Windproof module, Astronergy, etc. This indicates the trend of higher expectations of module reliability in the face of hailstorms.

Recent findings from a study featured in the Renewable Energy journal cast doubt on the sufficiency of the existing IEC hail resistance tests. The research highlights a potential shortfall in the standards, noting that the assessment of hailstone impacts with diameters exceeding 25mm is not mandatory. This insight points to a need for enhanced testing protocols that more accurately simulate the rigours of extreme weather, thereby bolstering the ability of photovoltaic modules to withstand such conditions throughout their service life.

The wave of industrial consolidation is growing ever more pronounced, shaping the landscape with each passing day. Manufacturers are trying to pull themselves out from the low-price competition to maintain their own operation and the long-term stable development of the entire industry.

“The essence of technology innovation revolves around the long-term customer value,” Chris Zou, vice president of Jolywood told PV Tech. “The criterion for judging whether we are on the right path is whether we bring reliable long-term value to clients.”

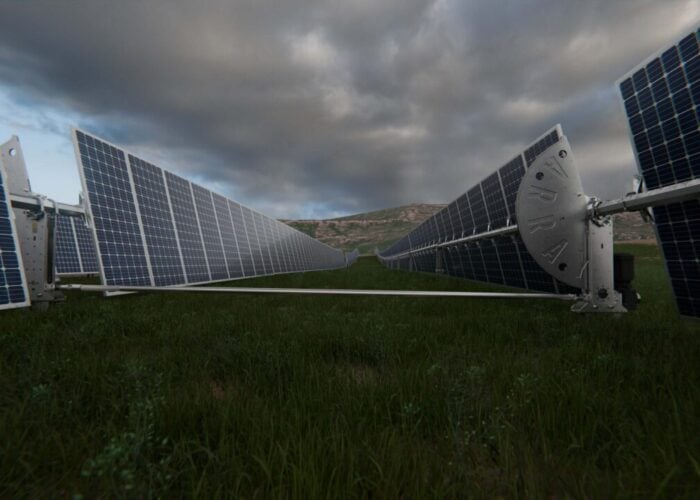

Jolywood Windproof Module: higher reliability for climate challenges

Last year, Jolywood released the Windproof Module, featuring n-type fully tempered one-stop encapsulation solution. The combination of tempered glass, transparent mesh backsheet and Backbone steel frame renders the Windproof Module as one of the most reliable options for extreme climate challenges, ensuring a high energy yield capability throughout the entire lifecycle.

In addition to tempered glass for protection against hail, the Backbone steel frame used in Windproof Module provides additional reliability during other extreme weather events like windstorms and snowstorms. Thanks to its unique design in both material and construction, the Backbone steel frame boasts a strength that is 50% greater than that of traditional aluminium frames. This enhanced strength reduces the likelihood of the frame’s hole positions tearing during windstorms and minimises the risk of module deformation under severe wind and snow conditions.

“More attention shall be paid to a manufacturer’s commitment to quality and innovation,” Zou said. “This market calls for more rational participants to get it back on track. Manufacturers should not only compete for market share but also take a long-term view to understand the true needs and wants of end users and the application fields.’’

As the PV industry continues to push the boundaries of innovation, it is essential to ensure that the advancements in module design do not compromise the long-term reliability and stability of solar projects. This requires a thoughtful approach to material selection, with a focus on maintaining a margin of performance redundancy, especially in regions prone to large hailstones. By doing so, the industry can ensure that the solar projects stand the test of time, providing clean and reliable energy for decades to come.