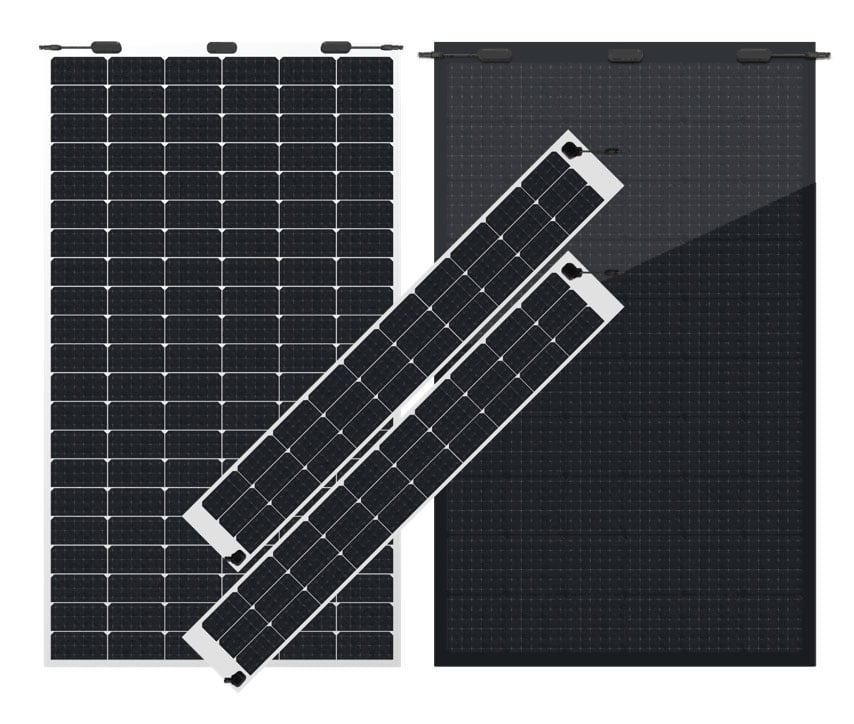

Chinese solar cell developer Sunport Power announced its “full black” series of solar modules, based on its Metal Back Contact (MBC)2.0 technology, at SNEC 2023 last month. The technology builds on a previous generation of technology, the C10-Pro panel, which was first announced at the 2021 edition of SNEC, and brings together several innovations for the solar power sector: heterojunction technologies (HJT), a metal wrap through (MWT) structure and a conductive foil back sheet.

Market & applications

The full black PV panels are designed for use in utility-scale power generation and power plants, and on residential and commercial rooftops, and Sunpower’s next generation of modules will build on these goals. Crucially, the MBC2.0 technology is a refinement of the MWT process, that moves all electrical components from the front to the back of the panel, significantly improving the conversion efficiency of the module.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

Industry challenges

Constraints of space and temperature are particularly relevant for domestic rooftop installations. Sunport has tried to overcome these challenges with the full black panels by aiming for a high conversion efficiency, so residential users can maximise their solar generation potential, and by including the reflective foil sheet, which could help regulate the temperature of the panels, to ensure they can operate as efficiently as possible.

Technical solution

The main features of the full black panels are those that look to optimise efficiency. An HJT cell can achieve higher conversion efficiency figures than other kinds as it combines a crystalline silicon cell with layers of thin-film silicon.

The MWT manufacturing process, meanwhile, involves the drilling of holes into the cell, and their filling with silk screen printed paste, to connect emitters on the front-side of the cell to the back via these filled holes. This removes the need for metal cables to be draped from the front-side of the cell to the back, improving the overall efficiency of the cell by ensuring that as much of the front-side of the cell as possible is clear for receiving sunlight.

Unique features & benefits

According to Sunport, the MWT process reduces the amount of shade falling on the panel by 3%, the module’s maximum power output can reach 700W and boasts a conversion efficiency of up to 22.8%. The module’s foil back sheet serves another purpose, as it can conduct electricity.

As a result, receivers on the panel can be connected to the sheet itself, rather than each component having to be affixed to another particular component, which Sunport notes will reduce the panel’s working voltage.

Availability

The modules are currently available.