Yezin Taha, Founder and CEO of Nevados Engineering, on how solar tracking technology can help eradicate the still common practice of levelling sites prior to installing solar panels – and thus avoid the problems, environmental impact and cost associated with site grading. This is an executive summary of a recent white paper by Nevados.

Grading, or the process of levelling land, has been an essential step in the construction of large-scale solar facilities since the earliest days of the PV industry. While the practice is common in all types of civil works, mass grading is inherently destructive to the natural landscape, and thus increases both the costs and the risks associated with solar development, permitting, and construction. Minimising the negative consequences of grading is particularly difficult and expensive at green‑eld solar projects on hilly terrain. These sites have become increasingly common as the utility-scale market expands and matures.

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

The greater the scale of grading, the more significant the environmental risks and the greater the permitting burdens. When grading is widespread and/or poorly managed, the costs of mitigating erosion, revegetating the landscape, and preventing stormwater pollution can dramatically increase construction timelines and costs as well as impact long-term operations and management budgets for solar assets. In certain communities, especially in the rural US, grading for solar projects has triggered local opposition to solar that stops projects in their tracks before construction even begins. It’s time to end the practice of mass grading.

Here’s the good news: mass grading is no longer required for large-scale solar deployments that use trackers to boost energy yield. New all-terrain tracker technology developed and innovated by Nevados has enabled the solar industry to build high-performing, cost-competitive solar farms that respect the land without the need for grading.

The Grading Process For Solar Projects

In large solar developments on uneven land, cut and fill grading is employed to achieve level ground. This consists of scraping high points off, then using that soil as well as imported soil to fill low points. Hundreds of thousands of cubic yards of soil may be moved during this process.

When land is graded, topsoil is typically stripped or covered, destroying the ability to farm or plant the land. Soil stabilising plant roots may be removed, which escalates erosion and increases sedimentation to downstream areas. In severe cases, erosion and sedimentation issues may violate local watershed protection regulations, harm plants and animals in local streams and lakes, and cause lengthy construction delays.

Level terrain has long been a requirement for utility-scale PV installations because conventional solar ground-mountings can only be installed on flat land. However, viable green‑eld sites that meet key developer requirements (i.e., flat topography, proximity to transmission infrastructure, low cost) are now scarce: in many markets, solar projects on any parcel of level, rectangular property that is well-located for utility-scale PV deployment.

As level sites continue to dwindle, developers are more and more limited to installing solar assets on hilly terrain. Many EPCs have turned to mass grading to achieve the flat land required for conventional tracker technology on available project sites. The greater the scale of grading, the greater the risks – and the greater the costs if issues arise.

As the industry matures, the risks of grading for solar projects are rapidly garnering increased attention from regulators. In the US, many localities are becoming savvy to the risks of grading for solar farms, implementing moratoriums and local level restrictions on solar projects within their jurisdictions. In areas where such measures are in place, grading functionally halts projects.

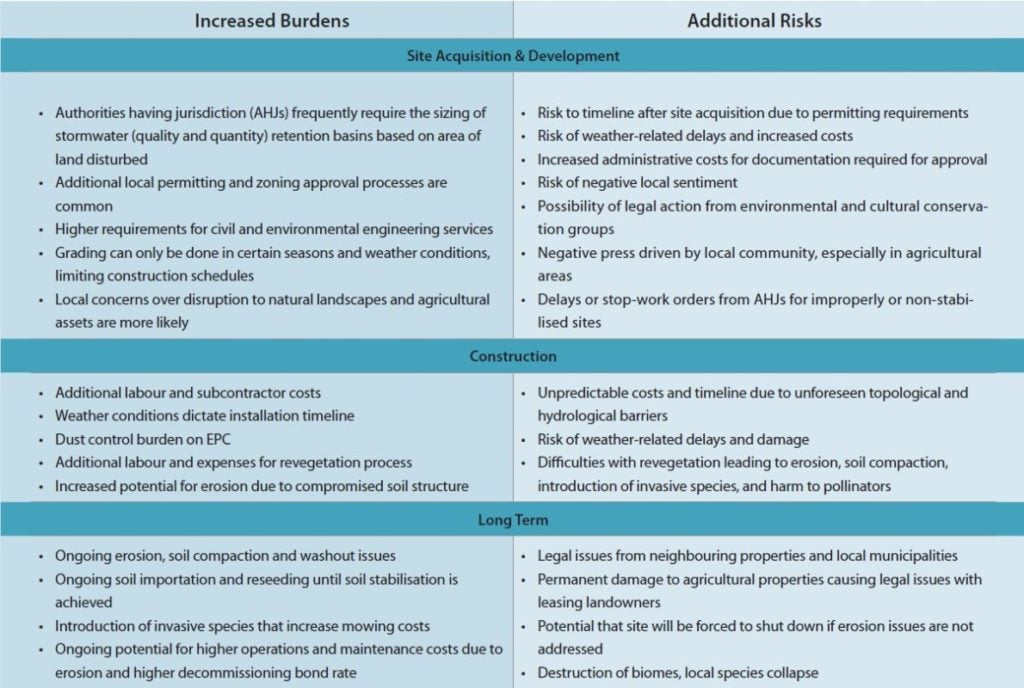

Grading Increases Project-Level Costs and Risks

According to industry leading engineering firm Primoris, US solar projects that are subject to Stormwater Pollution Prevention Plan requirements average an additional cost of $0.75 per watt. The costs are even higher for sites with significantly variable topography.

As detailed in the table above, grading increases the risk of permitting challenges, project construction delays, and cost overruns. All of these risks add up to higher costs and less profitable projects.

Grading Invites Unexpected Problems

Unforeseen costs are many and varied when site preparation plans include mass grading. At every level of execution, a graded solar project site runs higher risks of unforeseen delays and unanticipated costs.

Seasonal constraints on grading activities mean that in many regions, a graded site may require additional months to accommodate weather related delays, and the limited windows when grading can be executed. Vulnerability to extreme weather during and after grading is completed further increases the risk of increased costs and delays for a project.

Hidden geological features which are discovered during the use of large-scale excavation equipment can delay or even completely derail a project reliant on major restructuring of site topography.

Additionally, the high cost of dust control is an often-overlooked additional burden on developers who choose to grade during site preparation. Especially in dry and drought-affected regions, dust control measures are necessary to preserve local air quality whenever grading occurs.

In water-scarce regions, this can mean that in addition to the equipment and labour required to conduct dust control activities, water must be trucked onto a site at great additional expense.

Decommissioning bond rates may also pose an increasingly substantial liability for graded sites. As the risks to site infrastructure, negative environmental impacts, and the scope of regulatory compliance burden associated with grading become more widely understood, the grading process will soon become a major red flag to bond issuing agencies.

Leveraging Technology to Eliminate Grading

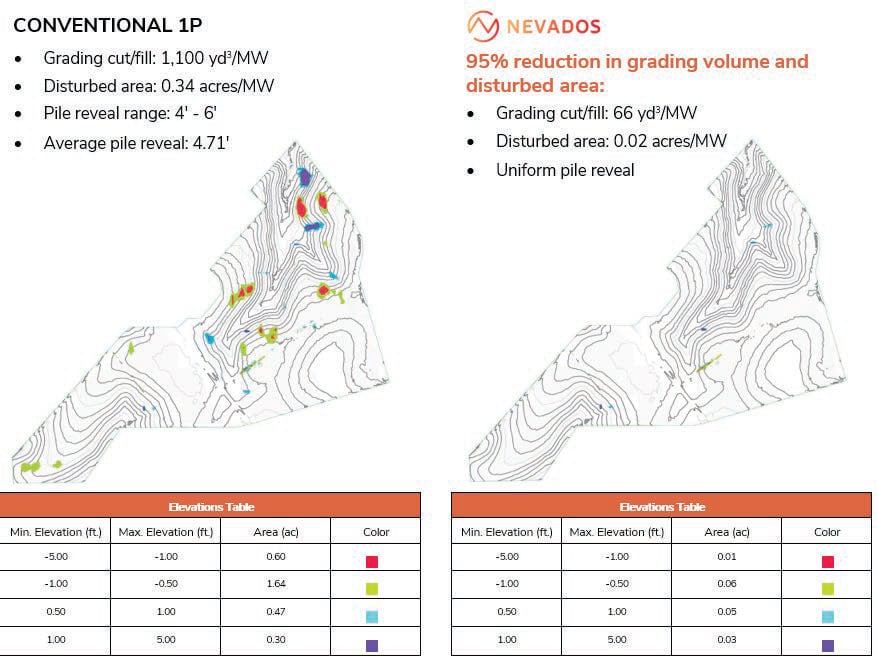

The 50 MW Iris Solar facility in Washington Parish, Louisiana is a case study in utilising Nevados’ integrated all-terrain solar tracking technology platform to dramatically reduce grading requirements.

Primoris, the construction and engineering firm that built the Iris facility, conducted a desktop study comparing earthwork and grading requirements at Iris for conventional 1P trackers vs. the Nevados technology platform. The study revealed that Nevados trackers reduced grading requirements and disturbed land acreage by 95%.

Primoris ultimately utilised 13MW of Nevados trackers in conjunction with 37MW of conventional 2P tracker technology for the Iris project. The cost-effective hybrid solution maximised utilisation of available land for solar production and minimised grading.

Nevados: An Integrated Solar Technology Platform

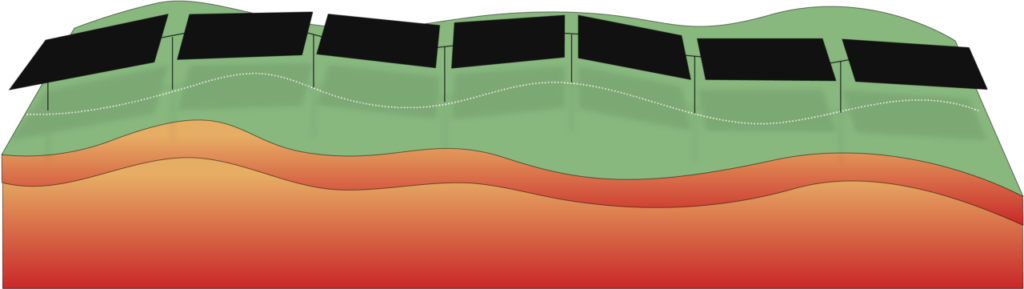

Nevados solar trackers use a proprietary product design that is engineered to eliminate or greatly reduce grading requirements on solar projects. The structures are uniquely characterised by highly flexible bearings and non-continuous torque tubes. Nevados maintains constant reveal heights which results in less above ground steel than is typical for 1P trackers.

Most trackers require flattening the land because they use a continuous torque tube across an entire row. Nevados trackers have segmented torque tubes and cost-effective flexible bearings, so they can accept angle changes of up to 15 degrees (26%) between posts and all bearings can handle maximum slopes of up to 37% (20 degrees). Nevados trackers also use standardised short piles that reduce steel as compared to conventional trackers.

No terrain is the same, so the Nevados solution is highly adaptable and customisable. We offer three separate bearing options with the same mounting and construction method for a tracking structure that moulds to variable topography. Bearing types can be mixed and matched throughout a project site to maximise available land for solar deployment.

The Nevados tracker system is designed for easy installation. The tracker has very few steps for assembly because the driveline and factory-assembled bearing are integrated into the same assembly. No specialised tools, jigs, or fixtures are required for installation. The entire system has only two bolt sizes with two torque specifications.

Non-continuous torque tubes, shorter pilings, and large tolerances also simplify and speed up the installation process. The shorter torque tubes are easily handled and installed by two people. Tracker installation occurs at chest-height, so no ladders or step stools are required. Torque tubes and straight bearings auto-align during installation while articulated bearings are hand-aligned whenever they are used. Solar modules also self-align during installation with top-clamp clips that can easily accommodate different module sizes.

The Nevados team engineered every aspect of its technology platform with topography in mind. It includes proprietary performance optimisation software, TRACE. Each row is programmed with its own tilt schedule to prevent all row-to-row shading for any topography and ensure maximum energy yield.

Call to Action

Grading is a destructive practice that undermines the solar industry’s ability to consider itself an environmentally responsible power source. Grading also introduces serious risks throughout the project lifecycle, which can threaten the long-term financial performance of solar assets and the viability of project development in rural areas. As variable topography becomes less the exception and more the rule in the identification of greenfield sites, new project sites are more vulnerable to the negative consequences of grading than sites that were developed in the past.

Continuing to engage in mass grading as an industry standard is likely to engender further regulatory action, preventing the continued expansion of the solar market into new geographies.

Fortunately, the harms and inherent risks of grading can be easily avoided with the All Terrain Tracker technology from Nevados. Nevados’ technology opens up potential greenfield sites that have previously been deemed non-viable for utility-scale installations. Additionally, older sites that utilised fixed-tilt racking to avoid intensive grading can increase energy yield by upgrading to All Terrain Trackers from Nevados.

The future of utility-scale solar cannot rely on the destructive strategy of mass grading. It is time for project developers and EPCs to end this practice by leveraging the most advanced technology from Nevados.

Author

Yezin Taha is the founder and CEO of Nevados Engineering. Nevados provides a comprehensive All Terrain Tracker (ATT) solution for the solar industry that eliminates the need for grading on almost any site. He founded Nevados to enable the installation of solar power plants in less time, at lower costs, and in more locations.

Q&A with Yezin Taha, Nevados Founder and CEO

PV Tech Power: Nevados has strong views on mass grading for solar projects. What exactly does it entail and what makes it such a destructive practice?

Yezin Taha: Mass grading is a heavy-duty construction process that flattens the land. Thousands of tonnes of topsoil and the vegetation that it supports are ripped from the earth, denuding the landscape. I was first exposed to mass grading for solar projects as an independent engineer conducting technical due diligence for investors. It shocked me because solar PV technology is touted for its environmental benefits – yet the process of building solar farms was destroying local habitats. These personal encounters with the harmful effects of mass grading inspired me to found Nevados.

How does Nevados’ technology negate those adverse effects?

The Nevados technology platform helps developers and EPCs avoid mass grading and minimise grading requirements. We designed our tracker system for deployment on variable terrain from the outset – it is not just a flat-land tracker adapted for hilly sites. Using our tracker system allows developers to dramatically reduce land disturbance at project sites.

What are the cost implications for a solar assets operator which avoids grading a site? What other reasons make it attractive for them to avoid the practice?

The economic benefits of reduced and avoided grading go far beyond lower construction costs. Projects that are not graded require fewer and faster permits and reduced or eliminated revegetation activities, and they are far less likely to suffer from erosion and watershed management issues that result in fines from local authorities and drive up operations and maintenance costs over time.

How does the efficiency differ between an ungraded site deploying solar trackers and one that deploys conventional technology?

The Nevados Technology platform delivers the same or better efficiency gains as conventional trackers on graded sites. From a construction point of view, no alignment labour is needed to assemble the bearings, torque tubes, or modules. From a financing and layout standpoint, our team optimises the tracker layout, tilt schedules, and energy generation estimates prior to construction to allow the customer to both pack in more MWs and more accurately estimate energy generation prior to construction. Once the power plants are up and running, the highly accurate Nevados TRACE program enables the solar trackers to capture the most sunlight possible without casting shadows from one row to the next. This eliminates the typical rudimentary approach of sacrificing some sunlight capture to eliminate inter-row shadowing. With Nevados, asset owners can leverage industry-leading tracker-boosted energy yields without the risks of grading.

Has Nevados seen a significant change lately in the industry’s attitude towards grading? Are there notable differences between the regions where you operate?

Nevados focuses on the US as our key market, and attitudes towards grading are changing quickly here. The key driver is local community opposition to solar projects because of grading’s environmental impacts. Projects in states like Ohio, Virginia, and Connecticut have been cancelled because of local environmental concerns, and some communities have enacted strict regulations on solar development. Developers that seek to operate in these high-potential, relatively untapped markets have no choice but to minimise grading or face the increasing likelihood of protests at permit hearings.

What are the most promising countries/ regions for your products outside the US and why?

The most promising countries/regions for Nevados have highly topographic terrain and fairly mature solar industries, such as Italy, Spain, Australia, and Japan.

Can you envisage a solar power industry that operates entirely without graded sites?

I imagine a solar industry that operates entirely without mass grading every day. It’s the vision that drives all of us at Nevados. While we recognise that some land disturbance will always be necessary for large-scale solar development – after all, we need roads to truck in equipment and piles must be driven – we are committed to engineering the best technology solutions for reducing land disturbance. Solar deployments that respect the land are the future of the industry.