US quantum dot researcher UbiQD has signed a multi-year supply agreement with US solar manufacturer First Solar to supply its fluorescent quantum dot technology for use in the latter’s thin-film bifacial PV panels.

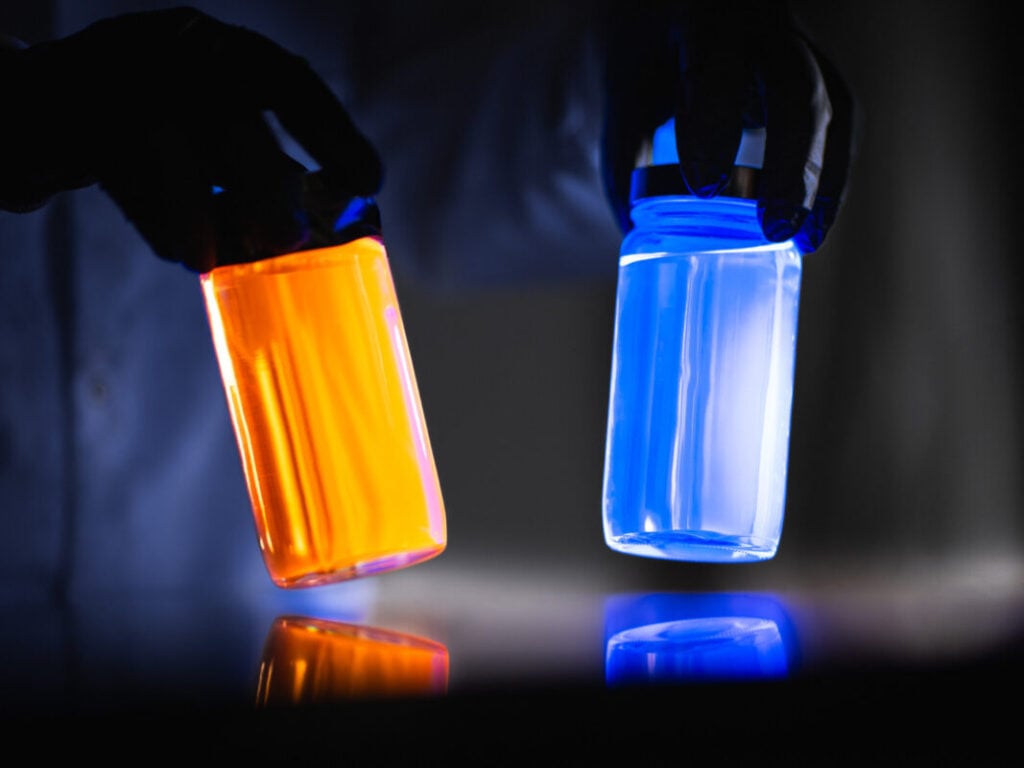

Quantum dots are tiny spheres of semiconductor material that could dramatically improve the conversion efficiency of solar cells as they can generate multiple bound electrons per incoming photon, compared to conventional solar cells that can typically produce one bound electron per photon.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

A report from the National Renewable Energy Laboratory (NREL) in the US suggested that the use of this technology could effectively double the theoretical efficiency limit of solar cells, and UbiQD’s own research echoes this, suggesting that quantum dots can more than double the efficiency of bifacial cells for specific wavelengths and colours of light. These efficiency improvements are particularly significant now as many cells in the research and development phase are approaching their upper limits of theoretical efficiency.

“This is a turning point for the quantum dot industry with this first high volume QD supply agreement outside of display,” said Hunter McDaniel, founder and CEO of UbiQD. The news follows the signing of a research agreement between the companies two years ago, UbiQD noted that, should the supply agreement yield results, it could produce over 100 metric tons of quantum dots per year to further the technology.

“This partnership showcases how US innovation and manufacturing can deliver differentiated performance especially at a time when making breakthroughs in efficiency and materials is more vital than ever,” continued McDaniel, highlighting the value of locating manufacturing capacity in the US at this time.

Earlier this year, the US passed more than 50GW of annual module manufacturing capacity, but its production of components and materials further up the supply chain, such as wafers and silicon, has been more lacking. With president Trump rolling back all manner of federal support for US solar projects, from manufacturing to deployment, ensuring a robust domestic supply chain of materials could be essential for the long-term health of the US solar sector.