The use of polyolefin elastomers (POE) as an encapsulant in solar module construction could limit the effects of degradation on the module’s electricity generation, according to research from the University of New South Wales (UNSW), Australia.

The key conclusion from a paper published this week said that POE encapsulants can limit the impact of degradation, particularly when compared to the traditional ethylene-vinyl acetate copolymer (EVA) encapsulant.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

‘The dark side of certain POE encapsulant: Chemical pathways to metallisation corrosion in TOPCon modules’ asses how the use of different encapsulant materials could affect the performance of a number of tunnel oxide passivated contact (TOPCon) modules, and builds on similar work completed by the university in 2024 that investigated the long-term performance of TOPCon modules in damp heat environments.

The 2026 study subjected four modules to 1,000 hours of testing at 85 degrees Celsius and at a relative humidity of 85%. One of these modules used conventional EVA materials, while three—dubbed POE-A, POE-B and POE-C—are commercially sourced TOPCon modules that use POE encapsulants.

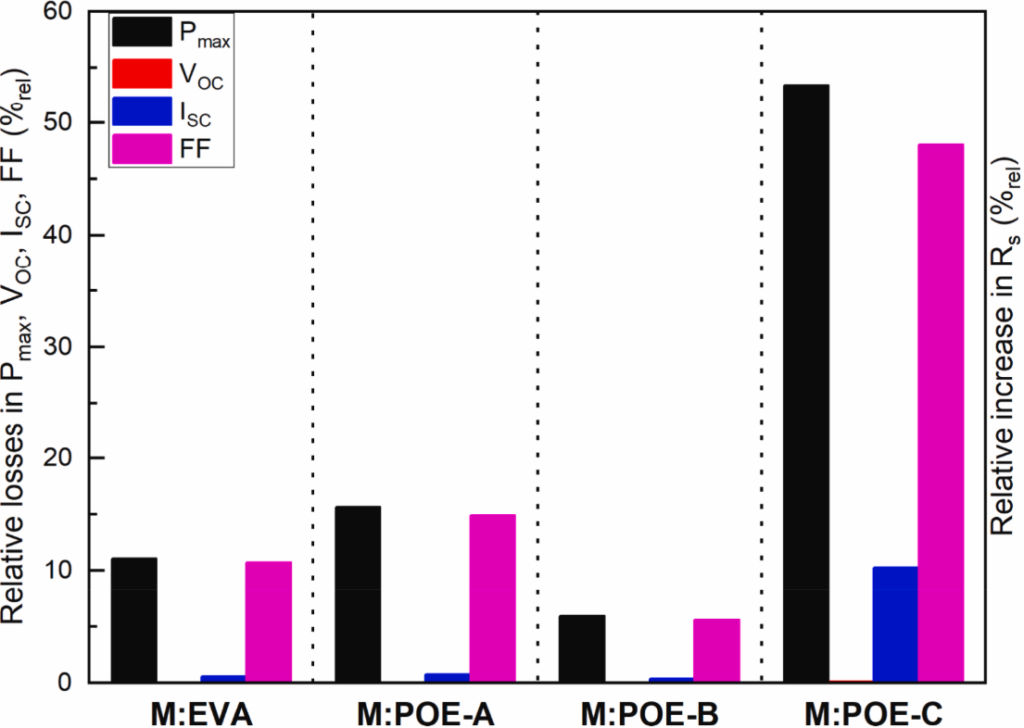

The researchers found that the maximum power output (Pmax) of the EVA module fell by 11% by the end of testing, compared twith a decline of 6-10% for the POE-A and POE-B modules.

Specifically, the research notes that modules with EVA encapsulants have a relatively high water vapour transmission rate, which leads to hydrolysis taking place in the module. This hydrolysis can then release acetic acid, which can erode the contacts in the cell, degrading long-term electricity generation. The POE-A and POE-B modules did not produce “measurable organic acids”, helping the modules maintain a slightly higher level of power output.

Differences within POE encapsulants

However, the researchers found that the POE-C modules suffered a power output loss of 55%, effectively cutting the module’s electricity generation in half, and by far the largest fall in output for any of the modules assessed. The researchers assessed the same module in the 2024 paper, at which time they described the power loss as “catastrophic”, and said that the results of both studies challenged the assumption that POE encapsulants are superior to EVA ones.

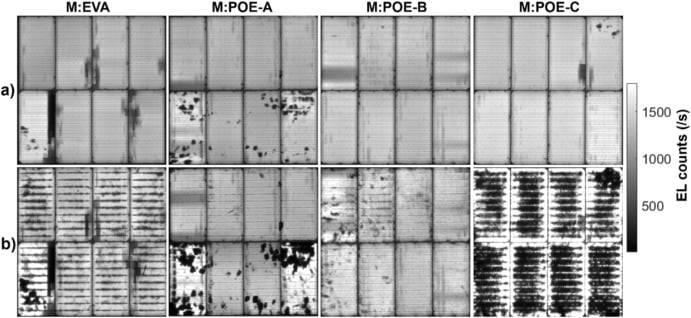

Electroluminescence (EL) imaging below shows the difference in power generation over time across the four modules assessed in 2026, with row A showing the modules prior to the testing, and row B showing the modules after 1,000 hours. The striking difference between the POE-C module, which endured an “exceptionally rapid” decline in performance from around the 500-hour mark, and the other POE products suggests that factors beyond encapsulant type affected module performance.

“Given that the rate of degradation was far greater than in any other module in this study, it is strongly suggested that an additive in the POE-C encapsulant, likely in combination with the soldering flux, may play a critical role in accelerating this failure mechanism,” wrote the researchers in their conclusions.

The report identifies three components of the POE-C module that contributed to this collapse in electricity generation. One is the “thermos-oxidative degradation” of POE, which affects all POE encapsulants; the second is the presence of weak organic acids at soldering points in the module itself, used in interconnections but ultimately not properly removed by the time the module was shipped; and the third is the presence of an ultra-violet absorber that itself can “undergo secondary degradation”.

As a result, the performance of the POE modules differs significantly, not exclusively because of the materials used in the encapsulant, but also due to the presence and performance of additional components and the overall attention to detail and quality in the module construction. This builds on an assumption made in the 2024 report, that “encapsulant reliability cannot be assumed uniformly across the POE class”.

As developers increasingly install solar modules in more extreme environments in order to expand PV deployments in line with decarbonisation targets, research like this becomes more significant. Earlier this year, researchers from the DEWA R&D Center wrote for PV Tech Premium about the challenges posed by dry heat environments like deserts, and this week’s research builds on earlier work completed by UNSW that found that “hidden contaminants” could trigger power losses of as much as 16% in damp heat environments.