Utility-scale solar is evolving beyond traditional measurements, and performance ratio are one such metric that is likely to become obsolete, replaced by more modern criteria such as availability metrics, where an O&M/asset operator is judged not on how much power is generated, but on how frequently a site is operational.

What is performance ratio (PR)?

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

The performance ratio (PR) is a measure of the quality of a solar PV plant independent of location and is often described as a quality factor. The PR is stated as a percentage and describes the relationship between the actual and theoretical energy outputs of the PV plant. In technical terms, PR of a plant for a period is energy measured (kWh)/(Irradiance(kWh/m2) on the panel x Active area of PV module(m2) x PV module efficiency. PR is a measure of the performance of a PV system. It considers the availability of the grid, the minimum level of irradiation needed to generate electrical energy, and irradiation levels at a given period. The optimum analysis period is normally one year.

What is plant availability?

The plant availability (PA) describes a PV plant’s operational status, which is generally a reflection of component and system reliability (uptime, downtime, and condition states). It is calculated as a percentage to represent the time that the power plant is available to provide energy to the grid or be thought of as the plant’s uptime. Solar PV plants usually have little downtime resulting in a higher percentage of availability; uptime of 98% or more is considered good. The availability factor is generally based on the real-time monitored parameters.

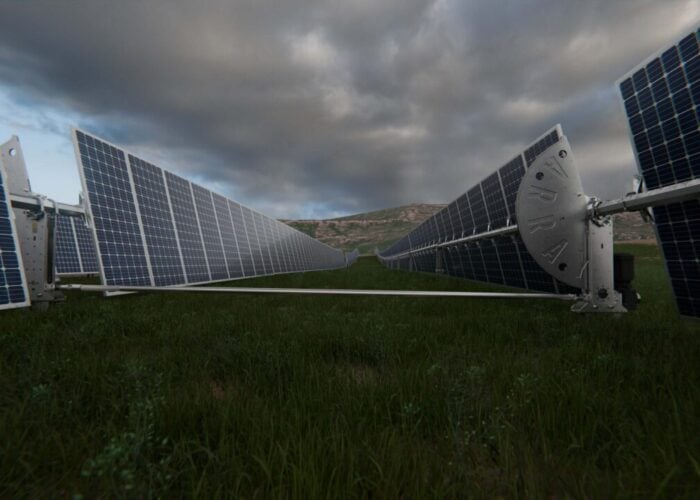

Today’s utility-scale PV plants using the latest technology panels, inverters, trackers, etc are generally running at a very high level of performance to start. Furthermore, PV power plants are long-lived assets expected to remain in service for 20 years or more. With that in mind, it is an operations and maintenance (O&M) team’s biggest focus to maximise plant availability – keeping the plant running.

Weather is hyper-local

Since PR is a location-independent measurement over a longer period of time, it runs contrary to the respected concept that all weather data is a hyper-local phenomenon, including critical parameters for PV monitoring. The understanding that most real-time weather parameters dramatically change over a very short distance confirms the need for more localised weather sensors instead of relying exclusively on national or government-owned services, met stations near airports and radar data.

Maximum PA requires real-time data

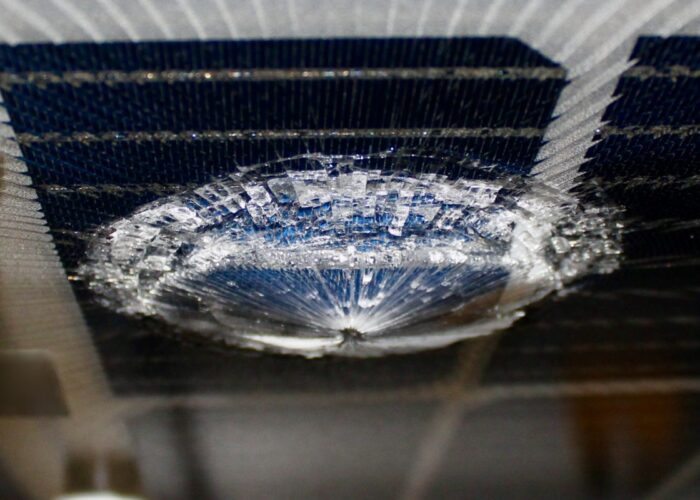

To secure a PV plant’s maximum uptime, it is essential to have real-time monitoring of wind speed as a part of a PV tracker system. Data from a PV plant weather station can trigger a pre-defined max wind threshold which automatically puts the tracker in a wind-stow mode and prevents any damage. In other words, if wind sensors around the site detect a high wind speed, trackers will automatically move to a near-flat position to avoid mechanical failure of the structural support. PV trackers can be found with availability guarantees, with separate language that assigns damages based on an availability threshold. Damages may also be determined from energy production losses based on the uptime of the tracker. It should be noted that high winds are the most common cause of damage for photovoltaic systems.

Additionally, PV plant availability is also related to ‘energy availability’ in the daylight, making irradiance another critical measurement.

Weather data for PV plants

The key meteorological parameters used for PV plants are irradiance, ambient temperature, wind speed, and precipitation. Most PV monitoring software calculates the real-time optimal PV production based on the irradiance value, the temperature of the PV panels, and the total panel surface area/rated performance. But as previously mentioned, wind speed is also an important data parameter. Additionally, with panel soiling in mind, the level of precipitation is good to know, expecting that a decent rainfall can wash off pollen, agricultural and construction dust, bird droppings, and other soiling factors.

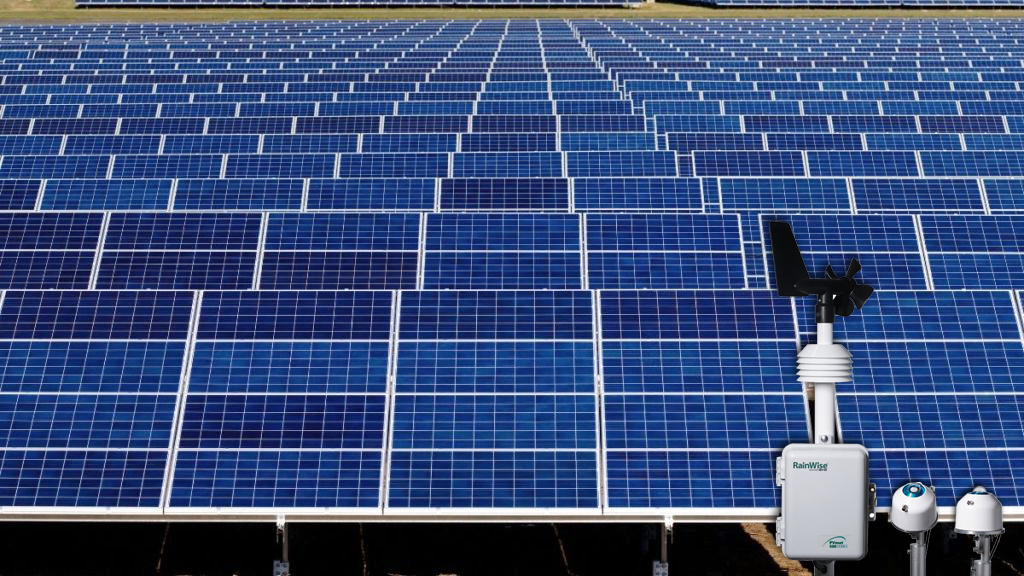

PV monitoring weather stations

Obtain real-time meteorological data relevant for utility-scale PV plants from a professional weather station tailored for PV monitoring. The kind of weather station system often used for utility-grade plant monitoring can be several individual sensors connected to various I/O ports of a datalogger. However, for ease of installation, “all in one” weather stations are becoming more popular for utility-scale monitoring. The RainWise PVmet 500 is an example of a compact all-in-one weather station explicitly designed for PV efficiency monitoring.

The PVmet 500 offers all irradiance parameters, such as global, plane of array, albedo, and diffused. All irradiance sensor standards and technology are supported – first and second class, secondary standard and silicon diode (Class A, Class B, and Class C) – in addition to reference cell sensors. This SunSpec standard weather station also meets the IEC-61724-1 standard for PV monitoring.

O&M’s typical responsibility for plant availability

All requirements relating to preventative and corrective maintenance, performance monitoring, and reporting must be clearly stated in the O&M contract, along with the frequency with which these activities need to be conducted. This allows contractor performance to be measured and, if necessary, challenged. It is now customary for an O&M contractor to guarantee plant uptime performance during the contract term.

Conclusion

To summarise, while the performance ratio is still used on most plants, there is no doubt that there is a shifting focus to plant availability metrics among O&M’s responsible for utility-scale PV plant upkeep. As related to a PV plant, the weather is a hyper-local phenomenon; indirect assumptions and interpolations are often inaccurate. Nothing is more critical than getting real-time meteorological data parameters that will alert any situation that can affect the optimal up-time or notify specific preventive maintenance needs.