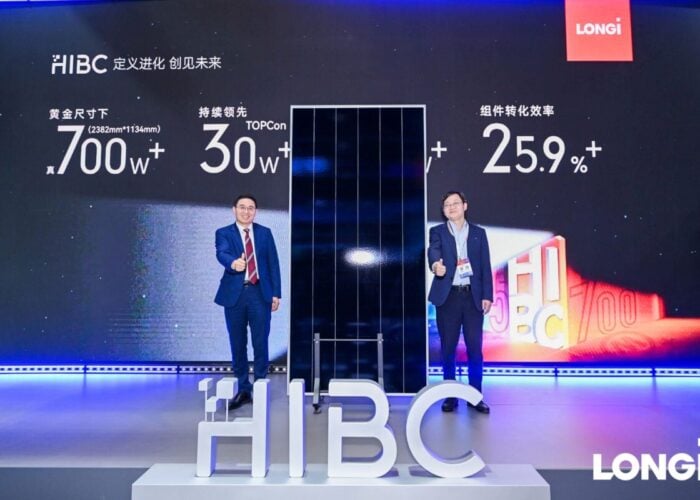

As the industry leaves behind p-type technology, most module manufacturers have either chosen tunnel oxide passivated contact (TOPCon) or heterojunction to jump towards n-type modules, with some opting for back contact (BC) cells to transition towards the new technology.

Solar cell producer and module manufacturer AIKO is among the latter who combined its knowledge in cell technology along with its know-how from more than 1,000 patents to focus on BC modules. “Patents are becoming increasingly important in China, as you want to protect your own developments and have an edge over competitors,” says Frank Feldmann, chief scientist at Solarlab AIKO Europe, adding that the company has filed many good patents on all back-contact (ABC) cell technology.

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

Even though TOPCon seems to be the preferred choice for many companies across the globe, Feldmann expects that while other companies will eventually want to adopt BC cells, AIKO decided to take the step much sooner. During Intersolar 2023 in Munich earlier this year, the company was awarded for its 72-cell white hole ABC module series for its high efficiency of 24% with a power attenuation rate of just 0.35% from the second year.

Feldmann says that AIKO continuously aims to improve the efficiency of its ABC cells and modules and targets a cell efficiency beyond 27%. “For the rooftop segment that means that AIKO will produce ABC modules with an output power of up to 475 W within the next two years.”

Whenever a new product or technology is introduced, there is always a concern that there might be some degradation issue that might have been missed in the initial test and only discovered once in the field. Feldmann gave the example of how mitigation strategies were found with p-type PERC cells’ light and elevated temperature induced degradation (LETID) which was discovered early on.

This meant that project planners and engineers accounted for some safety margin and assumed a higher degradation rate. “Now with the new technologies such as TOPCon, heterojunction or ABC, people ask the very same questions. Are there some degradation modes which we don’t know of? To this end, the interplay between different materials needs to be well understood,” says Feldmann, adding: “At AIKO, we are subjecting our ABC modules to extensive tests beyond IEC standards. Importantly, we try to tackle certain degradation mechanisms not simply by choosing a different encapsulant but by making the ABC cell itself more resilient. For instance, we carefully optimized the metallization so that it’s resistant to acidic corrosion. But we also look at different encapsulation materials, so that we can further mitigate impacts, like potential induced degradation.”

Moreover, one of the main advantages of BC cells is that the technology can integrate passivating contact for both polarities, whereas this is more complicated to do for TOPCon cells, says Feldmann.

“This means you will always have some parasitic absorption losses at the front side in this polysilicon contact. Whereas with the ABC cell, that is placed conveniently on the rear side,” adds Feldmann about the advantages of ABC cell compared to TOPCon.

The other main aspect of ABC cells is the lack of use of silver, which makes the modules much more sustainable in view of a TW-scale market.

AIKO first started targeting both the residential and commercial and industrial (C&I) markets – with an eye to launch a bifacial module for utility-scale in the future – due to a bigger benefit for customers of these markets in terms of higher efficiency of product. “If you compare an installation with the same power output, then of course, you will need fewer modules from us. That also means that your balance of system cost will scale accordingly. So less labour, less area usage, and so on,” says Feldmann. This gives BC modules an edge not just compared with PERC (passivated emitter and rear contact) but also with TOPCon, adds Feldmann.

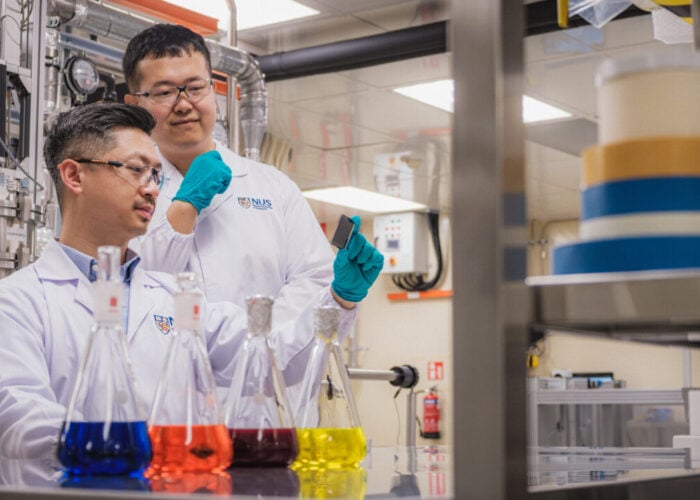

Solarlab AIKO Europe’s looking into perovskite technology

Despite the transition from p-type to n-type still in its way, everyone is already looking towards the next big technology that will rule the solar industry. One of the major contenders in this race is undoubtedly perovskite, for which we covered extensively on PV Tech and can be read here.

This is one of the missions of the AIKO’s Solarlab in Freiburg, Germany, with the lab looking into the future of solar PV, and among the technologies is perovskite. “We believe that perovskite silicon tandem solar cells are a serious contender for the next solar cell generation,” says Feldmann.

At the moment, for two terminal (2T) devices most researchers are using heterojunction cells, says Feldmann. That is due to the inherent compatibility with perovskite cell processing. This is not to say that TOPCon cannot be used, but requires some modification, which is the same for ABC cells. “Of course, then, we are talking about three terminal cell configuration, which performs superior in terms of energy yield but one has to have a close look at the module interconnection.”

Feldmann explains how researchers from the US National Renewable Energy Laboratory (NREL) and the Institute for Solar Energy in Hamelin (ISFH) have explored these matters for perovskite technology.

“2T tandem cells require well-balanced top and bottom cell currents and work less efficiently in case of spectral variations or bifacial application as the sub-cell currents are no longer balanced. However, a 3T tandem cell can, for example, extract excess current generated by rear illumination via the bottom cell.

“However, this requires an additional circuit and the cell interconnection becomes more complicated. That’s why for a back contact cell, a voltage-matched 2-terminal configuration where the perovskite is deposited on the front glass could also be of interest.”

Despite perovskite activity gaining momentum in the past few months, we might still be far away from seeing its commercial implementation, says Feldmann.

“The biggest concern is of course reliability. And that also includes bankability. If you want to develop a project with perovskite modules, the financing parties need to have the trust that the modules are stable for 20, better 30 years. If you can only guarantee a 10-year lifetime, then you do not have a chance against mature silicon modules for instance.”