Scientists in Australia have reported positive results from using copper plating to protect tunnel oxide passivated contact (TOPCon) PV cells against contaminant-induced degradation.

A study by researchers from the University of New South Wales (UNSW) has demonstrated how front-side copper metallisation can help reduce efficiency losses commonly seen in TOPCon cells due to corrosion build-up.

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

Despite TOPCon’s rapid emergence as the dominant cell technology in the solar market, concerns have emerged that the technology has a generic susceptibility to corrosion. Damp-heat testing of TOPCon devices has resulted in what the study described as severe degradation, with the main cause identified as the impact of harmful contaminants, particularly sodium chloride, on the front metallisation.

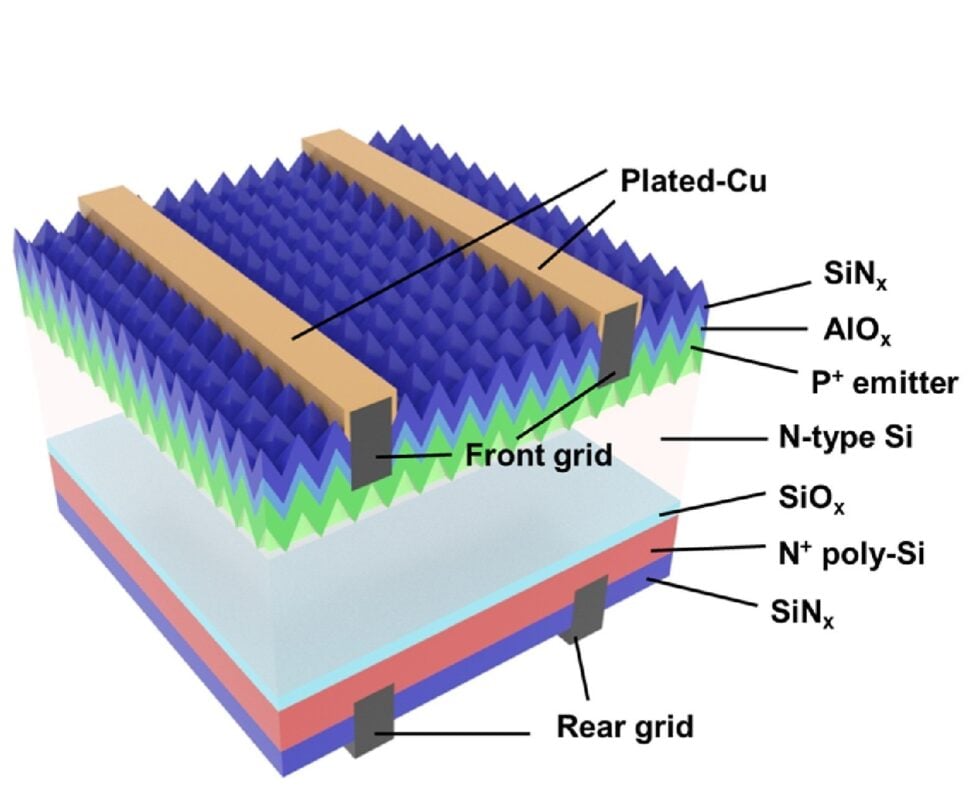

In a paper published in Solar Energy Research and Materials, the UNSW researchers described how they applied a 1μm copper plate on screen-printed TOPCon solar cells to assess its protective effect under damp heat conditions.

After six hours of damp-heat testing, the bare sample experienced over 80% relative degradation, compared to an 11.5% relative drop in efficiency in the copper-plated batch. The researchers said the severe degradation in the un-plated sample was in “good agreement” with their previous work.

“We also show that the Cu plating process results in a considerably denser contact, which hinders the penetration of contaminants,” the researchers added. “Consequently, the method presented in this work enhances the stability of photovoltaic technology with corrosion-sensitive contacts during field operation, thus contributing to an increase in lifetime and reduction in levelised cost of electricity.”

Reducing material costs

In addition to the performance benefits of the copper plating method, the researchers also noted its relevance to ongoing efforts to reduce material costs in PV cells and modules.

As outlined in the latest instalment of the International Technology Roadmap for PV (ITRPV), the extensive use of silver in PV cell production is likely to come under growing pressure as global demand increasingly outstrips supply. Silver consumption in PV technologies therefore needs to be reduced to avoid a further cost challenge for the industry.

The UNSW researchers highlighted the fact that the apparent success of the copper plating method indicated the potential of reducing silver consumption and thus material costs without “sacrificing the solar cell efficiency”.