Chinese module producer DAS Solar is planning a 5GW manufacturing facility focused on producing high-efficiency back contact cells.

Last week, the Weining County Branch of Bijie Municipal Bureau of Ecology and Environment in Guizhou released the public announcement information of the “Environmental Impact Assessment for the Construction Project of 5GW XBC High-Efficiency PV Cell Production in Weining County”.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

The published information shows that the developer of this project is DAS Solar (Weining) Co., Ltd. The project covers a planned land area of 177,000 square meters and will include the construction of a battery production workshop, a chemical warehouse, wastewater treatment facilities, a 110kV substation and various supporting infrastructure.

At present, the project is only in the environmental impact assessment public announcement stage. DAS Solar and the local government have not yet announced the specific construction schedule, nor disclosed the final capital budget.

Combined TOPCon/back contact architectures

At this year’s SNEC Exhibition, DAS Solar exhibited a DBC module named “Diamond”. This product has a nominal output power of 670W and a module conversion efficiency of 24.3%.

From the perspective of R&D routes and product moves, DAS Solar has begun to shift to a dual-track development path of “TOPCon + BC”. The company has named its own BC technology route “DBC (DAS Back Contact) Technology”, which is an integrated innovation solution—it not only migrates the silicon oxide/polysilicon passivated contact structure in TOPCon technology to the back of the cell, but also combines the full-back contact design.

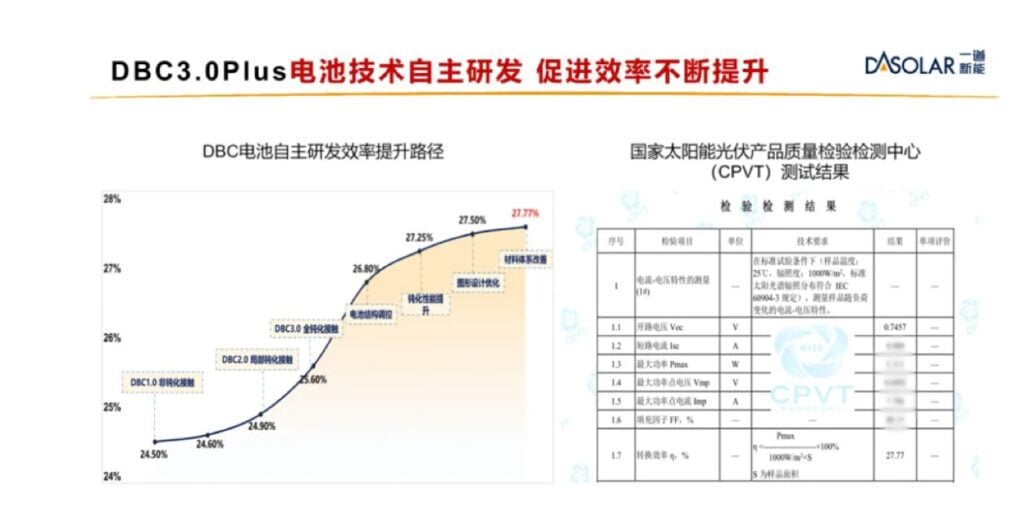

Zhang Kangping, general manager of DAS Solar Central Research Institute, said at the 21st China Photovoltaic Academic Conference that since 2020, DAS has migrated the company’s advanced SiO₂/Poly-Si passivated contact structure to the back of the cell, combining TOPCon with the BC structure, thereby creating the DBC cell technology with fully independent intellectual property rights. Currently, the DBC cell technology has iterated from version 1.0 to 3.0 Plus, with efficiency increasing from 24.5% to 27.77%.

On 11 September, DAS Solar announced that, according to the test report from the “National Solar Photovoltaic Product Quality Inspection and Testing Center (CPVT)”, the efficiency of the independently developed DBC cell reached 27.77%, and the open-circuit voltage increased to 745.7mV, breaking its own record.

It is reported that the DBC 3.0 Plus technology relies on TOPCon 5.0, uses an n-type silicon substrate, and both the n-region and p-region adopt the SiOx/Poly-Si passivated contact structure.

DAS Solar said that to realise the integration of TOPCon and BC architectures, its R&D team had achieved several technical breakthroughs. These included:

• High-precision laser patterning technology to achieve finer electrode grid lines

• An embedded diode system to provide provide real-time hot-spot mitigation by rerouting current from overheated zones, enhancing long-term reliability

• The realisation of high-efficiency full-area P/N region hybrid passivation technology by constructing a composite passivation film layer on the cell surface

• The adoption of zero-busbar metal interconnection technology to reduce silver paste consumption, achieve precise adaptation between materials and battery structure and lower the silver paste consumption of DBC cells

• The use of black silicon textured light-trapping technology to enhance the anti-UVID capability of cells.

Zhang said that by achieving both high reliability and low cost, DAS Solar has gained the capability to mass-produce the third-generation DBC technology.