Looks matter when it comes to PV modules. At Kiwa PVEL, our independent extended reliability testing has revealed an increase in the number of visual inspection failures over the last year, specifically related to delamination defects.

As we’ve often noted, changes in an individual module’s unique Bill of Materials (BOM) can have big impacts to its long-term reliability and performance. As module producers update their manufacturing processes and deploy new types of encapsulant materials, and as more modules are deployed to high-temperature environments, issues related to delamination can arise that impact project safety and performance.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

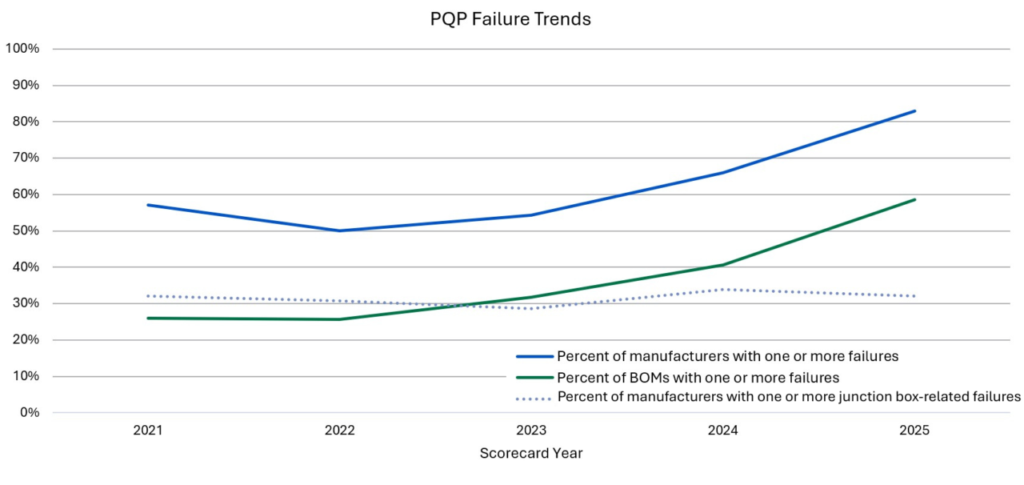

Throughout our suite of testing, the Product Qualification Program (PQP), Kiwa PVEL conducts visual inspections of modules to identify issues that cause premature field failure. Modules are examined for delamination, corrosion, broken or cracked surfaces and other ‘major’ defects using the IEC 61215 and IEC 61730 criteria. In 2025, we reported the highest number of PQP failures in our annual PV Module Reliability Scorecard report. Visual inspection was once again the leading failure category, with 60% of all failures detected during visual inspection.

Where does delamination occur?

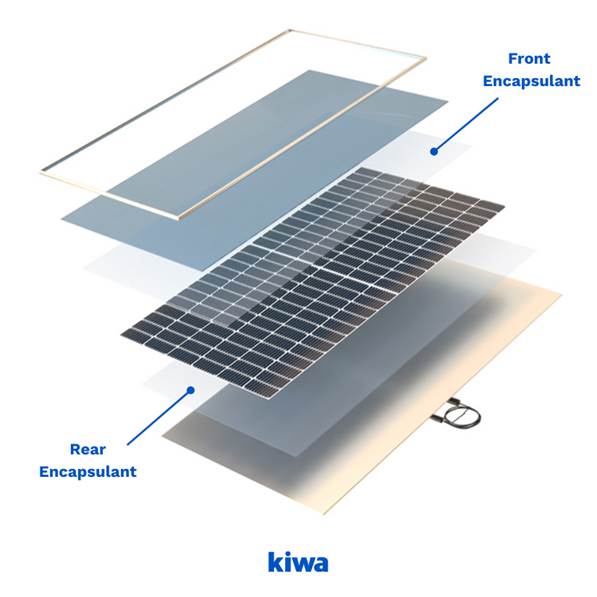

Within a module’s construction, front and rear encapsulants bond solar cells to the front and rear surfaces of the module, respectively. Degradation of these components can result in delamination and/or corrosion.

Delamination occurs in modules for a variety of reasons, ranging from poor materials choice, usage of thinner encapsulants and/or poor lamination processes. Since 2012, when we introduced the PQP, we’ve uncovered frequent examples where the choice of BOM had direct impacts on module reliability. In many of these cases, different BOMs being tested had the same model number, nameplate and datasheet, but the use of different materials yielded different results.

Bubbles, bubbles, everywhere!

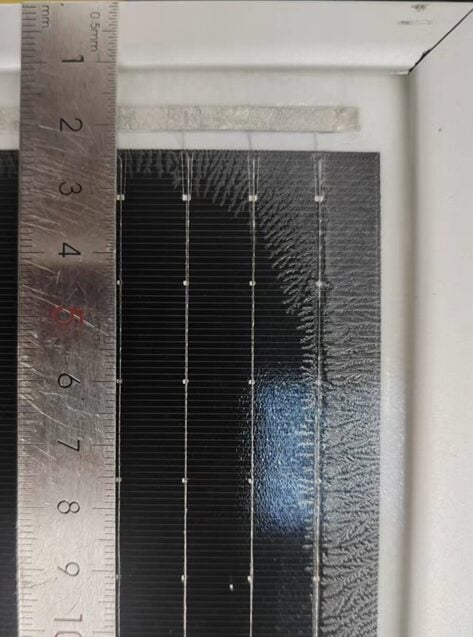

The most common issue arising from PQP testing over 2025: delamination around the perimeter of glass//glass modules. This defect involves bubbles appearing after damp heat (DH), thermal cycling (TC), potential induced degradation (PID) and/or other PQP tests. In some more egregious cases, these bubbles were even observed at incoming inspection of the PQP samples.

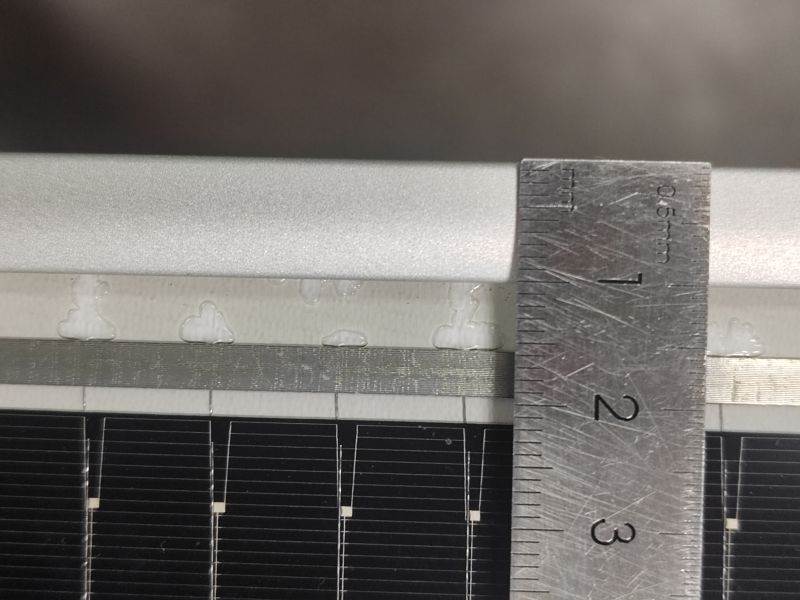

While they may cause moisture ingress and corrosion over time, the more pressing concern is reduced electrical creepage distance because, unlike encapsulant, air is not an electrical insulator. This means a higher risk of inverter electrical insulation faults, ground faults or even arc faults between the module’s electrical circuit and frame. Kiwa PVEL is aware of this issue occurring at PV sites, where modules with delamination around the perimeter suffered electrical arc faults leading to catastrophic failures and severe safety risks.

In the example in Figure 3 (see below), this particular BOM used one type of encapsulant, resulting in one of the most significant cases of delamination we’ve seen after 1,000 hours of damp heat conditions. However, two other BOMs with the same model type from the same module manufacturer that used different encapsulants did not have any delamination issues.

In another recent example (Figure 4) from our damp heat test, a glass//glass module from a different manufacturer likely had edge pinch issues where the laminate is thinner around the perimeter due to encapsulant squeeze out/flowing during lamination. This can lead to module breakage (as highlighted in a recent paper from the National Renewable Energy Laboratory), and/or the lack of encapsulant along the edges can cause bubbles around the perimeter of the laminate, which again presents significant safety hazards.

The above cases are not unique. We reported 9% of manufacturers eligible for the 2025 PV Module Reliability Scorecard experienced delamination failures along the edges of their glass//glass modules following DH testing, and that number has steadily increased since the Scorecard’s publication. These have been consistent reminders of the importance of proper lamination.

Across our PQP and batch testing population, delamination defects will sometimes appear during IEC 61215 duration testing (such as post-DH1000, post-TC200 and post-PID96), but we also see some BOMs that don’t exhibit bubbles until the extended PQP durations of DH2000, TC600 and PID192. In many cases of delamination defects, the bubbles were not there during pre-shipment visual inspection. Therefore, both PQP and batch testing are imperative to know if these issues exist.

With all of this in mind, Kiwa Solar’s Procurement Best Practices include PQP testing for BOM and module design qualification, specifying the acceptable BOM(s) in the procurement contract, and conducting third-party production oversight to ensure that the specified materials are being utilised. We also strongly recommend batch testing of the mass-produced modules to ensure consistent quality and reliability. Leveraging these tools can bring site owners increased confidence that their modules will perform to expectations for decades – and look good, too.

Tristan Erion-Lorico is VP of Sales and Marketing, and Max Macpherson is Data & Reports Manager at Kiwa PVEL.