The impact of extreme weather on solar installations has become an increasing concern in recent years. The effects of climate change are being felt more acutely around the world at a time when the economics of solar allow it to be installed across a wider range of locations. With this growth has come a shift from insurers, with more than 80% of claims value originating from weather-related damages, according to insurer Lloyd Warwick International.

Fraser McLachlan, CEO at renewable energy insurance company GCube, says: “Over the last two or three years, there has been an exponentially increasing risk profile when it comes especially to solar and extreme weather.”

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

While traditional insurance perils – earthquakes, hurricanes, and floods in flood zones amongst other events – can be modelled and therefore more easily managed, there are increasing instances of extreme weather that fall outside the normal bounds.

“What we’ve seen though, over the last 3/4/5 years is more losses in renewables with regards to extreme weather,” adds McLachlan. “Things like hail, which is way more unpredictable, heavy rain, tornadoes, small scale wind events, microbursts and things like that, which have caused significant damage to renewables, and in themselves are much harder to mathematically model from an insurance perspective.”

With insurance costs rising in response, solar developers and operators are increasingly looking to ‘weatherise’ their systems in an effort to best protect their sites. But how do you design, develop and manage a solar system to protect it from extreme weather, especially if such instances are so unpredictable in their nature?

Pushing wind testing

Ensuring your solar system can survive extreme weather events begins at the design and testing stage of development. Alex Roedel, senior director of design & engineering at tracker manufacturer Nextracker, says one of the most common mistakes is insufficient wind tunnel testing of solar systems. This is particularly true with regards large-format solar modules, which are now being adopted en masse as solar system design principles mature. Larger chord and row lengths in these panels increase wind loads, putting them at greater risk of damage.

According to Roedel, one of the first considerations solar developers must make when looking at weatherisation is wind tunnel testing for all components. Nextracker suggests static wind tunnel testing, wake buffeting-based dynamic analysis, single- or multirow computational fluid dynamics (CFD) analysis and a full three-dimensional multi-row aeroelastic study. This allows companies to ensure their site can withstand not just static wind, but also aeroelastic wind effects that occur due to dynamic wind instances when installed and operational.

Most panels are designed to withstand wind speeds of 140 miles per hour (mph), although the regulations for installations vary from region to region. For example, in most cities in Florida where hurricanes are a concern, solar systems must be able to withstand winds of at least 160mph. Internationally, systems must pass a series of tests set out by the International Electrotechnical Commission (IEC) to ensure that they are weatherised, including IEC 61215 and IEC TS 62782, which include static and dynamic load testing.

While this provides a good basis, Roedel questions whether they go far enough, arguing that the tests aren’t comparable to real world events. For example, one test involves placing a bag of sand on a panel for an half an hour to test its ability to withstand load. This is not “indicative of real life” he says, highlighting that strong winds are not a source of constant pressure on a module, but flex throughout a storm. As such, when choosing modules for a project being developed in an area prone to storms, components must be tested beyond those standardised levels. While this testing is particularly significant for module choice, developers must also consider the benefits of tracking systems when planning a solar site in an area prone to high winds. A tracker would allow modules to be moved into a defensive stow position, based on the site configuration to protect the installation. By defensive stow facing them into the wind, it can dramatically reduce the load placed on the modules in such situations.

Additionally, sometimes it is the smallest components that can make the biggest difference in terms of protecting a solar installation from extreme winds says McLachlan. “We saw in Puerto Rico, for example, the way some of these projects were built, just spending another 20 cents on a different type of bolt to keep the actual panel more securely fixed to the mounting would have saved millions of dollars. But they wanted to save 20 cents a bolt, so they put the cheapest bolts in.”

Hail no: the benefits of dynamic systems

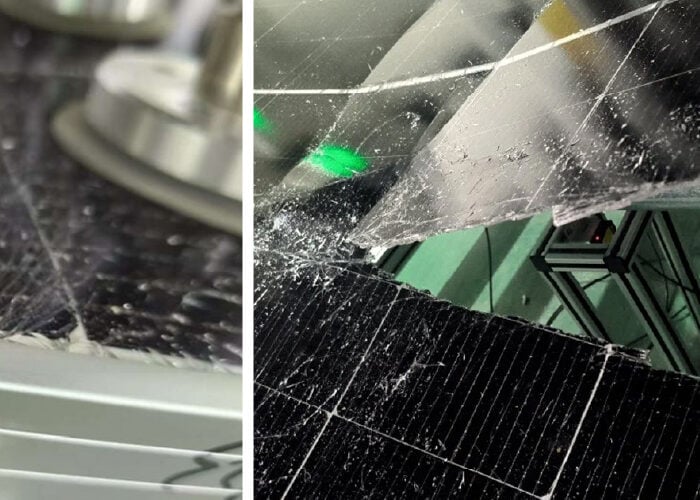

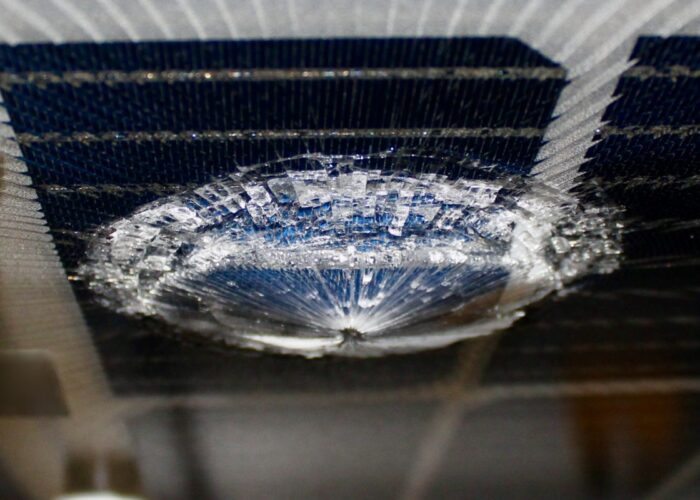

Beyond wind, one of the key weather risks for solar projects is hail. Hail testing has been in place in the solar sector since the late 1970s, and features 11 impacts of a one inch diameter ice ball, propelled at solar panels at a terminal velocity of 51.5mph. Nextracker also reserves criticism for the extent of the testing in this field, writing in a recent report that: “industry-standard qualification test requirements are not rigorous enough to characterise perils in hail-prone regions.”

Currently, all PV modules pass product certification hail impact tests, but with worsening weather the size and impact of hail is growing. In a test conducted by Nextracker and the Renewable Energy Test Center (RETC), the stow angle and direction of modules and their link to hail resistance was assessed. The study found that 300% more kinetic impact energy is needed to shatter framed PV glass in modules stowed at 60° versus a flat stow position.

A report produced by the RETC following the study stated that stowing modules facing into the wind at 60° can significantly increase the survivability of PV panels from 81.6% to 99.4% during a hailstorm. This again is particularly pertinent when looking at large-format modules, as the larger surface area and thinner glass makes them vulnerable to hail. The same can be said for the use of bifacial panels in areas prone to hail, with thinner glass leaving them more exposed to the impact of the ice.

“Hail, at least in the United States has rocked the industry,” adds Roedel. “There was one particular site in Texas that got hit with US$80 million of damage. So while bifacial panels might be great, what’s happened is we went from a standard 3.2mm thickness glass on the front side to 2mm on the front side and 2mm on the backside. Combine that with a larger format, what you have now is panels more vulnerable to hail and more vulnerable to impact.”

Taking advantage of snow: bifacial panels and the Albedo effect

There are occasions when extreme weather can work in a solar asset’s favour, for example using bifacial panels in snowy areas. A study by Sandia National Laboratories entitled ‘Snow as a Factor in Photovoltaic Performance and Reliability’ found that in winter months, bifacial-plus-dual-axis tracker units performed 41% better than bifacial fixed- tilt installations thanks to the rearside irradiance created by the higher Albedo factor.

This increased generation makes bifacial panels a key consideration for developments in regions more prone to snow, and are already enabling bifacial panels to push out into regions previously thought uneconomical. But there are still concerns developers must take into consideration, not least the impact of snowfall accumulation on the panels – blocking light but also creating a potentially damaging weight. A study conducted by Silfab Solar found bifacial panels were better than monofacial panels at self-shedding major snowfall even at low tilt angles. Those at a 20° tilt angle shed snow faster than monofacial at 40°, lowering snow-related production losses.

As such, when looking at components for solar developments in areas prone to snowfall, bifacial provides notable benefits, especially when paired with the flexibility of dual-axis trackers.

Keeping the air flowing: installations and extreme heat

As solar markets in the Middle East and other arid regions continue to grow, the risk presented by extreme heat increases too. Modules are generally tested to ensure they can continue to operate at or below 70° Celsius for 98% of the time according to Colleen O’Brien, principal engineer at Underwriters Laboratories. While modules can manage short excursions above this threshold, if it is likely that they will spend more significant amounts of time above it, there are modifications to the testing process and the modules themselves developers should consider.

The need for airflow is a key consideration in this regard given its ability to ensure that systems do not venture above that 98th percentile. Open rack systems generally provide sufficient airflow in utility-scale installations, O’Brien says, but it’s more complicated when looking at rooftop or building integrated PV systems where often they are in direct contact with the building with no cooling from the back.

While the current technical specifications allow for testing and modifications up to 90° Celsius, beyond that bespoke testing and modifications will be needed. According to O’Brien, in some regions like the Middle East, a module with an insulated back on a roof could exceed those temperatures and, as a result, would need custom research and development, as well as potentially new materials to be used inside the modules.

In slightly less extreme heats though, O’Brien notes that there are current industry wide recommendations for the encapsulant and backsheets. “In addition, the connectors and junction boxes that are used with PV modules, if they are used at elevated temperatures, should also be tested at higher temperatures in the qualification tests,” she says. “And for the PV modules, the testing that they undergo is modified, the hotspot endurance test, UV exposure test, temperature cycling test, and bypass diode tests are all conducted at higher temperatures, if the modules are to be rated for high temperature applications.”

Utilising a range of these tests should allow developers to ensure their module choice can withstand the extreme temperatures they are predicting. While as with other extreme forms of weather, having a dynamic installation that takes advantage of trackers systems can additionally help to mitigate some extreme heat. Should temperatures exceed 70° Celsius for longer than 2% of the time however, they can be used to rotate the modules away from the sun.

But this is not an ideal situation to find yourself in. “If you needed to rely on the tracker to move modules away from the sun to prevent high temperatures, you’re probably really close to the edge of exceeding the limitations of the products and it would be better to design them for the expected temperatures at that site,” says O’Brien. “But I think you could slightly reduce risk by monitoring PV temperatures and rotating them away from the Sun if needed. If temperature started to approach the maximum rated temperature, say 70°C, I think it’s possible.”

Smartening up O&M

When up and running, operations and maintenance (O&M) works can also help to manage the impacts of extreme weather on solar installations. This can be in small ways, like catching wear before it is exacerbated by weather.

“There’s a lot of exposed wiring in PV systems and I have seen wind cause displacement of the wiring over time, it can start to get damaged… and it could lead to arching, which could cause a fire or shock hazard,” O’Brien says.

Some of the impact of extreme heat like abrasion and degradation can also be addressed through monitoring and maintenance. If a site’s performance is falling, simple field work should be able to determine what the cause is and identify where modules need to be replaced, which can in turn prompt warranty checks, all of which can fall in the scope of works for an O&M provider.

Monitoring has undergone a technological jump in recent years, with Nextracker’s Roedel pointing to the impact smart controls have had on O&M. It’s possible now for people to manage large portfolios, of two or three gigawatts spread across the world all at once, simply by connecting them all using smart controls.

“You have a control panel that shows you everything on your sites, whether it’s wind, hail situations, there’s snow, there’s flooding, all these different aspects that you can read into using your interface. And so as the owner, you know exactly what’s happening on your site,” he explains.

“Comparatively, two or three years ago, without the software capability, you’d essentially be in the dark. And you’d have to send someone out physically to [the] site. So if we’re connected, and we know that health of every single tracker within our system, every single inverter within our system, that’s really going to have such great value to the owner.”

The growth in operational software has also allowed companies to increase the weather mitigation abilities of historic sites as well. For example, Nextracker is going back and installing flood sensors on sites which will lead to software updates that can manage the impact of extreme weather events like flooding and hail.

The next big concern?

As the solar sector continues to grow and push out beyond its traditional markets, extreme weather events are going to be a more common concern for many. But with the right testing that can educate the right component choice, and smart software to manage operations once up and running, the durability of solar is winning out.

Each installation will be different, with different concerns and considerations based on the site, but ensuring a level of flexibility in an installation seems to have few downsides and allows for systems to react to events that may not have been considered at development.

But stormier clouds could be on the horizon, especially as weather events become more severe and more common. The Texas winter storm in February 2021 was illustrative of wider trends given that a similar event happened a decade ago, and lessons were not learned in time. That these events are happening with greater regularity is of concern. “We weren’t talking about the dynamics of trackers in 2015. We weren’t talking about hail in 2018. What are we going to be talking about in 2025? What are we going to be talking about in 2030? That’s a big thing, and that’s what really scares insurers who have forced this conversation,” says Roedel.

“That’s why I’m just so big on the software aspect, because there could be a risk that happened next year that we don’t even know about today.”