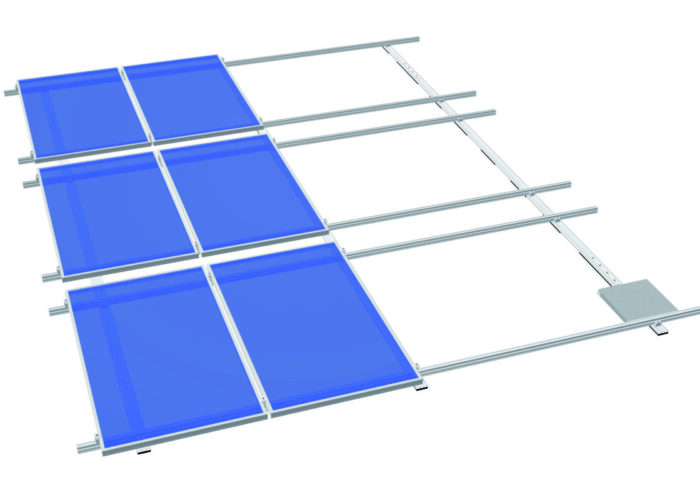

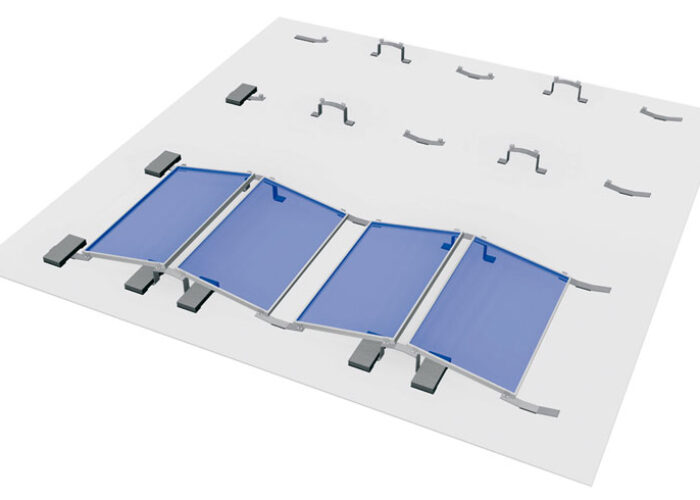

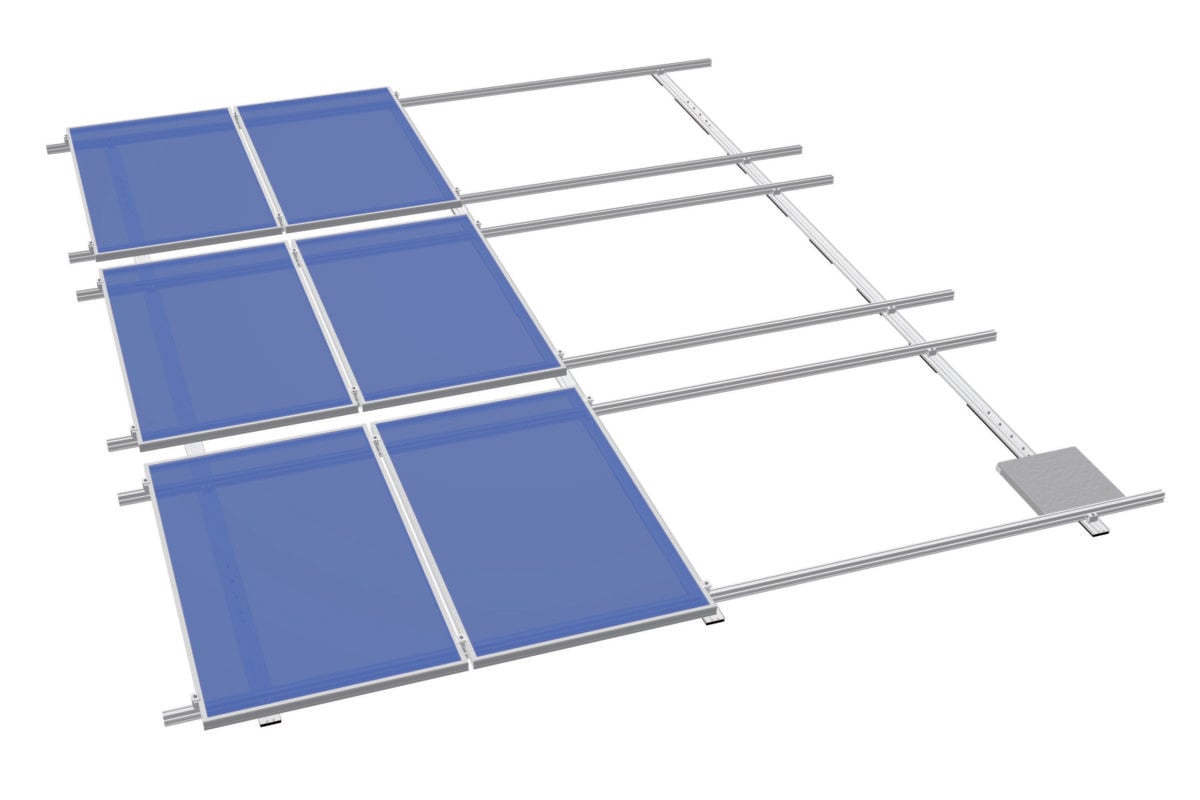

S:FLEX now offers installers a new, aerodynamic installation system for this rapidly growing segment of commercial buildings. ‘Flat Direct’ can be used on pitched roofs with up to 30° incline and guarantees short installation times with its pre-assembled components.

Problem

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

Non-penetrative installation of PV systems on pitched roofs with foil and bitumen roofing places high demands on the frame, especially on commercial buildings with low load-bearing reserves.

Solution

Flat Direct’s aerodynamic functionality is achieved with 11mm strong foam rubber pads. They are readily glued underneath the aluminium bottom rails of the system and are characterised by their high friction coefficients while allowing for a significant reduction of ballast. On top of that, the structural properties of Flat Direct with the air gaps between the modules produce a suction effect in the direction of the roof and achieve the best possible rear ventilation. Further advantages of foam rubber pads over conventional building protection mats are their good material compatibility with all conventional roofing materials. The migration of plasticisers from the roof membrane, leading to embrittlement, is prevented just as well as mechanical effects on the roofing. Long-term damage is reliably prevented.

Applications

Low-ballast pitched roof system for non-penetrative installation on foil and bitumen roofs.

Platform

The Flat Direct, which was developed in cooperation with PMT (Premium Mounting Technologies), is modular with the bottom and module mounting rails provided as standard products with prefabricated lengths. They are indefinitely extendible with rail connectors. One type of click-in mid and end clamps will suffice to connect modules of all frame sizes. The system is rounded off with optionally available covers for the cable channels integrated into the bottom rails. This way, string cables are protected against permanent and harmful environmental influences, UV radiation in particular.

Availability

June 2016 onwards.