This Premium article, which was one of the most read Premium articles in 2025, has been made accessible/free to all to offer a glimpse of our Premium and PV Tech Power coverage.

—

Chinese polysilicon producer GCL Technology has refocused its manufacturing processes following sustained challenges in the polysilicon market and exited its remaining investments in the Xinjiang Uyghur Autonomous Region (XUAR) of China.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

Yesterday, GCL announced that it had withdrawn its indirect shareholding in silicon rod manufacturer Xinjiang Goens, previously held via its subsidiary Jiangsu Zhongneng.

With this move, the company has “fully exited” direct and indirect investments into the Siemens method of polysilicon production in favour of granular polysilicon production.

FBR vs Siemens

Fluidised Bed Reactor (FBR) granular polysilicon production is more cost-effective and uses less energy than the Siemens method. However, it has traditionally struggled to reach the same product purity as Siemens production, which is required for high-efficiency solar products.

Broadly speaking, this is because of the contact that FBR polysilicon has with the wall of its container during the production process, as opposed to the separation between Siemens process rods and the reactor wall.

In 2021, GCL claimed that its FBR production had reached comparable purity with Siemens method polysilicon. Until recently, REC Silicon was a leader in the FBR space, producing polysilicon with this method in the US, though the company adandoned this business late last year.

In comments to PV Tech, polysilicon market analyst Johannes Bernreuter said: “GCL is not alone with FBR technology in China. Shaanxi Non-ferrous Tianhong REC Silicon Materials Co., Ltd. (TianREC), REC Silicon’s former joint venture, is also producing granular polysilicon; two new entrants have started constructing FBR plants. Most importantly, market leader Tongwei is building a 10,000 MT FBR pilot plant, according to an environmental impact assessment report announced by the government of Leshan, Sichuan province in February.

“With its large FBR capacity of 480,000 metric tons, GCL is certainly a strong promoter of the technology. Nonetheless…I believe that FBR technology will not replace the Siemens process, given the high purity requirements for n-type ingots and solar cells.”

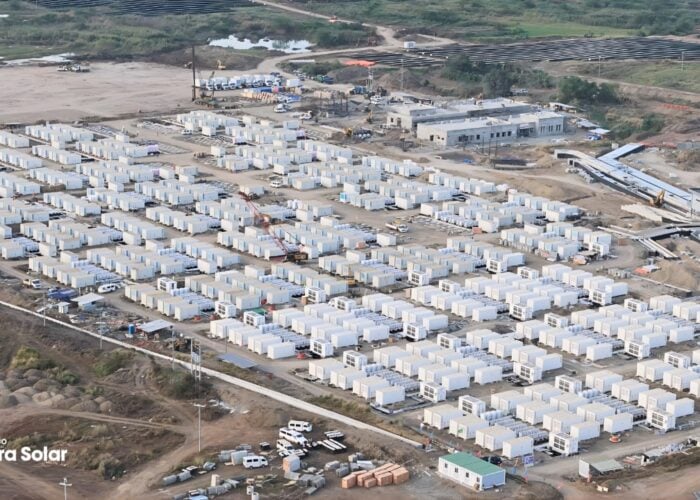

GCL also said it had now “redirected its focus” away from the XUAR to its four 100,000-ton granular polysilicon production bases across China: Xuzhou (Jiangsu), Leshan (Sichuan), Hohhot and Baotou (Inner Mongolia).

The XUAR region has become notorious for the international allegations of forced labour enacted by the Chinese state on the Uyghur Muslim population. In its announcement, GCL said a “representative emphasised the company’s commitment to human rights as a cornerstone of its operations”.

Allegations of forced labour in the solar supply chain have been known for at least the last four years, since the publication of the ‘In Broad Daylight’ report by academics at Sheffield Hallam University in the UK in 2021.

Polysilicon price slump

GCL has announced these changes following a challenging year for the company and the broader polysilicon manufacturing sector.

Bernreuter told PV Tech: “GCL has strategically moved in this direction in order to achieve lower production costs to remain competitive, partly driven by the higher electricity rate for GCL’s first production base in Xuzhou, Jiangsu province, compared to the low rates in Xinjiang and Inner Mongolia.”

Low prices, brought about by oversupply, saw GCL and its peers Daqo New Energy, Xinte Energy and Tongewi Solar post losses in the first half of 2024.

GCL posted US$400 million in losses in the first nine months of 2024, which it blamed on low polysilicon and silicon wafer prices.

The company said it saw the average cost of granular polysilicon fall below the selling price in January and February 2025, which it said “marks significant cost reductions and steady price increases.”

However, data from InfoLink, EnergyTrend and the Shanghai Metals Market (displayed below) shows that the average price of polysilicon is yet to significantly recover from its sharp drop over the last two years.

There is still disparity between companies’ nameplate polysilicon manufacturing capacity, their actual production and their shipments. GCL said its production capacity in 2024 reached 480,000 tonnes, while it actually produced 269,200 tonnes and shipped 281,900 tonnes over the year.

In December, Tongwei and Daqo New Energy both announced production cuts to minimise the impacts of price competition.

However, in a LinkedIn post last week, Bernreuter Research said that the apparent cuts in production were unlikely to last and would not have any significant impact on polysilicon prices.

Bernreuter said: “Since China’s monthly polysilicon output of somewhat less than 100,000MT is basically not lower than consumption, the inventory mountain piled up in 2024 is hardly carried off. This is why the polysilicon price has remained unchanged since early January.

“Moreover, new polysilicon production capacities in China are slated to come on stream in the second quarter. That is making a significant – if any – rise of the polysilicon price more and more unlikely in the coming weeks and months.”