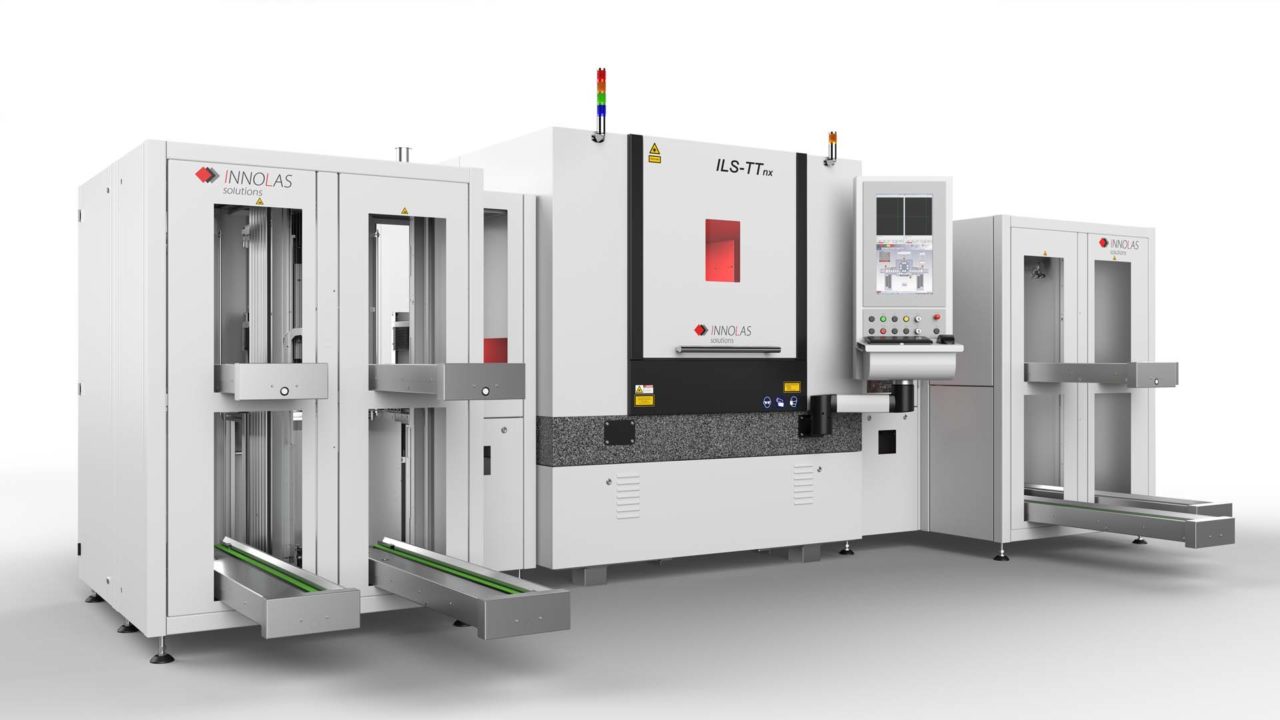

InnoLas Solutions has launched its new high throughput laser workstation for various applications with throughput up to 6000 wafers per hour (WPH). The ILS-TTnx (InnoLas turntable next generation platform) is based on InnoLas’ existing and proven rotary table machine platform with a multi process head configuration and a dual lane automation system.

Problem

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

In the past the throughput of laser machines typically was limited to 3000 to 4000wph while modern solar cell production lines are increasing their output above 4000wph. This means that laser machines are increasingly becoming a bottleneck in the fabrication of high efficiency solar cells. Should a solar cell production line be operating at a throughput of 5000wph and the throughput of the laser machine is limited to less than 4000wph, it could require two laser machines to be deployed in order to keep the overall line throughput and eliminate constraints. However, this would also increase the Capex (capital expenditure) required for the production line eliminate the bottleneck but the second tool would be underutilized.

Solution

The InnoLas Solutions, ILS-TTnx enables an increase in the throughput beyond 4000wph without increasing the tools footprint. The enabling innovation for the ILST-Tnx comes out of InnoLas know how in laser optics, such as multi-beam splitting as well as multi-pattern scanning. The compact design of the ILS-TTnx saves factory space and lowers the overall cost of ownership. With the ILS-TTnx InnoLas follows the ITRPV roadmap and enables the reduction of solar cell product costs, according to the company.

Applications

The ILS-TTnx laser workstation is suitable for various process applications such as Laser contact opening (LCO) for PERC solar cells, Laser doped selective emitter (LDSE), and front side LCO for the upcoming copper plating on Silicon (PoSi) metallization technology.

Platform

The ILS-TTnx can reach a throughput of up to 6000 wph and beyond. The machine can be configured as fully automatic stand alone platform with cassette to cassette operation, or integrated into any inline production system such as e.g. a screen printing line.

Availability

April 2017, onwards.