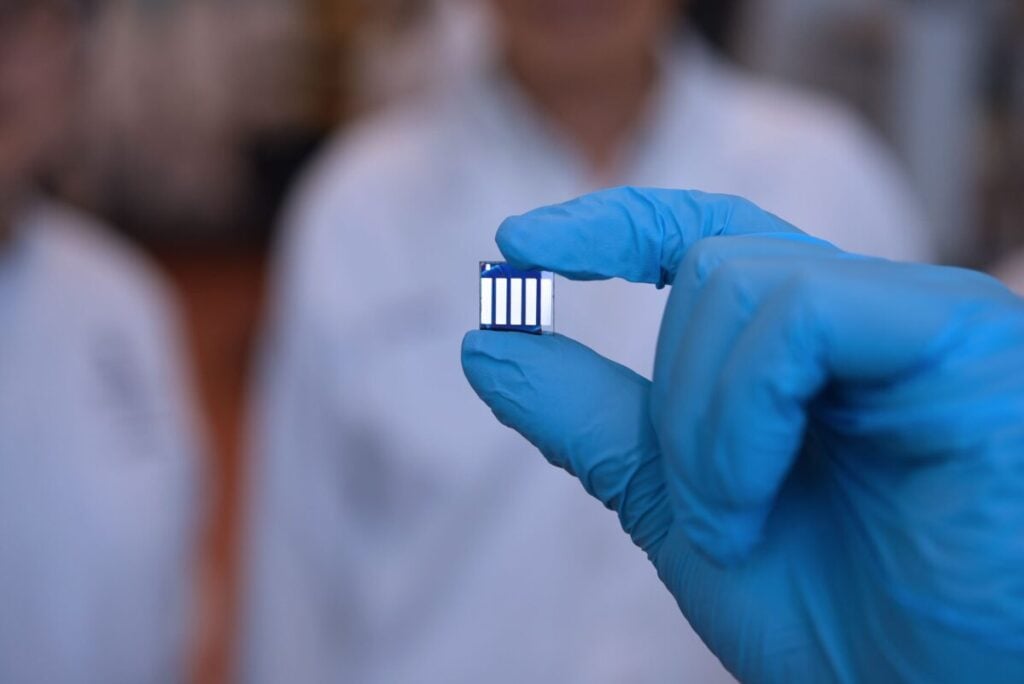

The University of Queensland has today announced plans to move ahead with commercialisation of its tin halide perovskite cell technology.

Last month, the Australian university revealed that it had achieved a world-record efficiency for the emerging cell technology, achieving a certified conversion efficiency of 16.65% – nearly a 1% increase on previous efficiencies.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

The technology, which the university has deemed “eco-friendly perovskite”, utilises a 2D/3D heterojunction architecture. This architecture can effectively regulate crystallisation and suppress defect formation to develop high-quality THP thin films, the university said.

The certified record efficiency was achieved by a team led by Professor Lianzhou Wang, comprising researchers from the University of Queensland’s Australian Institute for Bioengineering and Nanotechnology and the School of Chemical Engineering.

An alternative to lead-based perovskite

Speaking to PV Tech, Dr. Peng Chang, a research fellow at the University of Queensland and a member of the world-record achieving team, says the technology’s basis came from research into lead-based solutions.

“Our journey in solar cells started in 2013 when we looked into lead-based materials. This was the superstar coming out of South Korea and Japanese teams at the time,” Dr Chang explains.

“We then realised there may be some issues with commercialising lead-based materials. That’s why we started exploring lead-free technologies and replacing lead with other elements. We made good progress with tin, so we started exploring the THP technology.”

The benefits of THP solar cells

THP solar cells could provide multiple benefits over their counterparts, says Chang. These include cost competitiveness due to a lack of rare earth materials and being more environmentally friendly by replacing the often-toxic properties of lead with eco-friendly tin.

THP technology also possesses “desirable optoelectronic properties, which include ideal bandgaps (1.3–1.4 eV), high charge-carrier mobilities and low exciton binding energies.”

One key area of the research was the crystallisation process. Dr Chang explains that lead-based solar cells have a low-temperature process compared to silicon, which often needs very high temperatures to purify the silicon wafer and obtain high-purity silicon materials.

“We consider this quite an expensive process. For lead, the team can process at a temperature of 80 to 100 degrees Celsius to get very high-quality crystalline materials. This can provide us with a very good theorem for the solar cell materials,” Dr Chang says.

Tin-based perovskite, meanwhile, must be very hot before it reaches crystallisation, and this process is very hard to control, Dr Chang explains. It reacts much faster than its lead-based counterparts and thus can cause complications throughout the process.

As a result, it is normal for labs to achieve an efficiency of around 27% already using lead-based counterparts, comparable to silicon-based technologies. However, reaching this efficiency for tin-based technologies is harder as they are harder to control.

Dr Chang says: “In our recent work, we tried to regulate the crystallisation of tin-based perovskite. Because of our strategy, we can produce a relatively high-quality tin-based process. That’s why we can further improve the efficiency of the tin-based process. Currently, we can get 17% in the lab. We are still working on that. We are very confident that we may get around 20% efficiency this year.”

The potential to be used as an indoor solar cell

Another aspect of the THP solar cell technology undergoing advancement and research is its stability.

Dr Chang explains that the efficiency of the technology will continue to be advanced, with the team of researchers already guaranteeing a lifetime of around 20 years. However, Dr Chang mentions that the technology is relatively unstable compared to silicon.

“In the lab, we can get around 1,500 hours of stable operation under the light, with over 19% of the initial efficiency able to be retained. It works well, but we still need to improve the stability further,” Dr Chang says.

“We don’t expect to put this solar cell technology on rooftops at the current stage. Instead, we expect to use this solar cell for other applications, such as an indoor solar cell or some other flexible solar cell, which silicon cannot do.”

In this respect, Dr Chang believes the THP technology will be less of a competitor to silicon-based technologies and more of a complementary one. He explains that tin-based products will likely outperform lead-based technologies.

Eyes will now be set on commercialising and scaling the THP technology. In the immediate future, lab scaling will be undertaken to increase the technology to 100 square centimetres, with the world record achieving a cell of one square centimetre.

Once this has been achieved, the University of Queensland team will understand the technological feasibility of solar module integration. To advance the commercialisation process, the University of Queensland has just announced a partnership with PV solar cell manufacturer Halocell Energy, with a focus on indoor solar cells.