In an industry often described as a “solar coaster” for its ups and downs, Qcells has been steadily building towards America’s first, almost entirely integrated c-Si solar manufacturing ecosystem. From early 2026, the company will boast the only ingot-to-module PV production facility in the US when it completes its new factory in Cartersville, Georgia.

The timing of the new facility’s completion is less than ideal for the South Korean-owned company, with recent policy shifts having created new uncertainties for the US solar sector. But, as its global chief technology officer Danielle Merfeld tells PV Tech, Qcells is doubling down on its American manufacturing presence while simultaneously pushing the boundaries of next-generation solar technology.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

“The economics and the fundamentals [are] inherently tilted in our favour in that solar is the cheapest, fastest, easiest form of electricity with the best financial returns,” Merfeld says. “I feel like that’s helped buoy us a bit through all the changes, because that fundamental market truth hasn’t been impacted by policy. It can’t be.”

Building America’s solar manufacturing base

PV Tech spoke with Merfeld in the run-up to our PV CellTech USA event in California next week. There, recent developments in US solar policy will be under close scrutiny, and Merfeld will participate in a panel discussion on the subject of “PV manufacturing at a crossroads”.

To continue the analogy, Qcells, for now, at least, seems less at a crossroads than on a single-lane highway toward fulfilling its goal of bringing ingot-to-module solar manufacturing to the US. The company has been building its US manufacturing presence for seven years, beginning with its first factory in Dalton, Georgia, which opened in 2019. This facility now boasts 5.1GW of annual module production capacity. But the company’s ambitions extend far beyond this initial footprint.

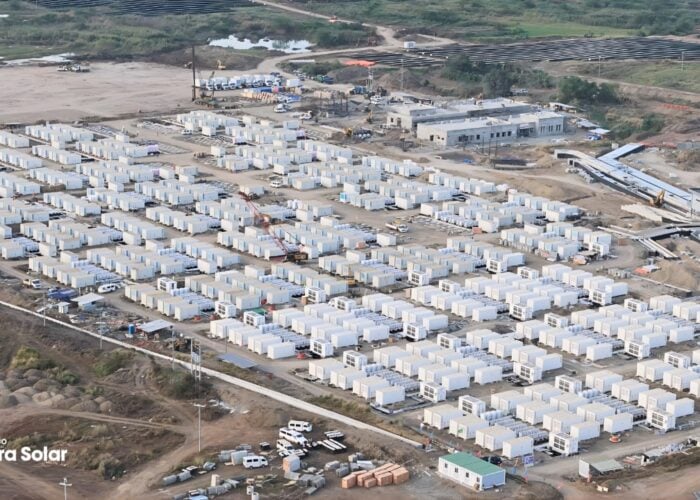

“In 2023, we started our second US factory in Cartersville, a little bit closer to Atlanta,” Merfeld explains. “This is a much more impactful facility because, in addition to modules, this is where we’re also putting ingot, wafer, cells and modules under one roof. It’s our integrated facility spanning about 2.4 million square feet.”

The module portion of the Cartersville facility is already operational, bringing Qcells’ total annual US module capacity to 8.4GW. “By next year, we’ll be producing nearly 45,000 solar panels a day in the US—over 1.6 million annually,” Merfeld notes.

The remainder of the integrated facility—the ingot, wafer and cell production lines—will be fully operational by early 2026, she says. Equipment is already being commissioned, with sample production runs and operator training underway.

What makes this development particularly significant is that Qcells will be the first company to establish a fully integrated c-Si solar manufacturing ecosystem in the United States, from ingot to module (with polysilicon being the only component still sourced externally, from South Korea).

“It’s equally exciting to see the people there,” Merfeld says. “We’ve got Georgia Tech graduates working with us on ingot and wafer production. They never thought they’d be working in an ingot facility in the US.”

Navigating policy disruption

Of course, the final stages of Qcells’ journey towards completing the Cartersville facility have been overshadowed by recent policy changes that have created significant uncertainty in the US solar market, particularly for project developers. However, Merfeld notes that the manufacturing policy landscape has remained relatively stable.

“From a policy level, the manufacturing policy is kind of untouched,” she explains. “The only change is really around whether a company is deemed a foreign entity of concern, because then they can’t claim the 45X tax credit, which gives us as domestic producers a competitive advantage.”

The more significant impact has been on Qcells’ customers—the developers who build solar projects. “Our major concern with those changes is the loss of the domestic content bonus or its early sunsetting,” Merfeld says. “That’s the piece of the incentive that makes customers choose American-made products, which is where we’ve positioned ourselves to excel.”

The domestic content bonus provides developers with an additional 10% tax credit on top of the base 30% investment tax credit when they use a certain proportion of American-made components in projects. With this incentive set to expire at the end of this year for residential systems and gradually from next July for others, the economic advantage for choosing domestically produced solar equipment will diminish, Merfeld says.

But while the sunsetting of tax incentives could create short-term market disruptions, Merfeld notes that many developers are engaging in “safe harbouring” activities to extend these incentives. “This is not going to have everyone falling off a cliff. There’s certainly enough planning for those sunsets to happen,” she says.

And beyond the current policy headwinds, Merfeld believes the future looks good for solar because demand for electricity is at an all-time high, driven by several factors, including the rapid expansion of data centres and artificial intelligence applications, which are dramatically increasing electricity demand in certain regions. “The demand for energy is rising for the first time in decades. It’s not just rising, it’s sharply increasing in certain regions,” she says.

The domestic supply chain advantage

Having a largely domestic supply chain provides Qcells with several significant advantages in today’s complex trade environment.

One is the security of Qcells’ supply chain, Merfeld explains: “We don’t have the same concerns around importing and whether something will be detained or whether there’s going to be a ship that’s going to be delayed.”

This factor has become increasingly valuable in the context of the tightening trade tariffs on solar imports into America, the incoming foreign entities of concern rules and the fact that US Customs and Border Protection has intensified scrutiny of solar imports under the Uyghur Forced Labor Prevention Act (UFLPA). Qcells itself recently experienced this firsthand when a shipment of cells from South Korea was temporarily detained.

“We recently had this shipment released,” Merfeld says of this development. “We’ve demonstrated effectively to the enforcement agents that we were in compliance with all US laws. We’ve had several of our shipments that were detained released now. Once we’ve demonstrated and had agreement that we meet the compliance, it should get easier.”

Another advantage of domestic manufacturing is the reduced carbon footprint. “There’s a huge carbon footprint advantage to manufacturing in the US,” Merfeld points out. “Customers who have commitments on embedded carbon are going to be choosing domestic content because they’ve got an inherent 20-30% benefit compared to other grids used to generate solar panels.”

Qcells recently became the first polysilicon-based PV producer to receive EPEAT ‘ecolabel’ certification for low carbon, meaning customers can reach their sustainability goals about 40% faster with its panels, the company claims.

Beyond these specific boxes that Qcells’ American manufacturing operation ticks, Merfeld says Qcells also meets the needs of companies that simply want to buy American: “There are customers who are really just committed to building out the US manufacturing base, and this is something that they’re standing by, to show their customers, if they’re utility or data centre developer or big tech company, that they are investing in US manufacturing.”

Pioneering perovskite technology

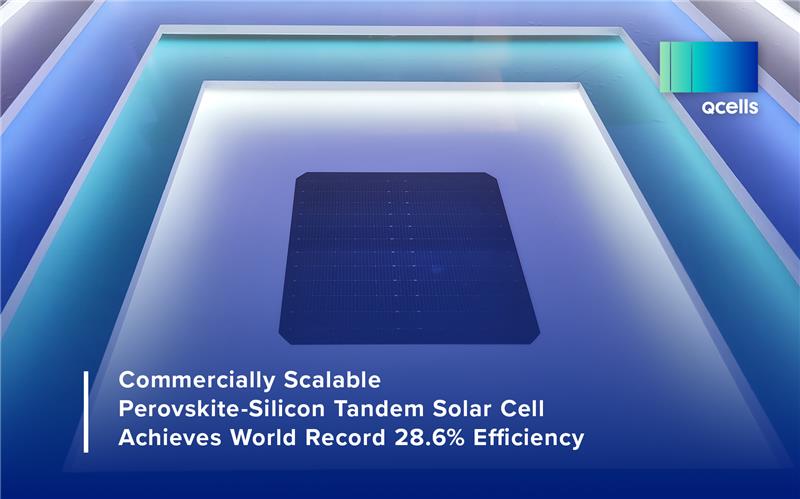

Aside from positioning itself to meet current market demands, Qcells also has an eye on the future and the industry’s likely evolution. One area where the company has been particularly active is in its development of perovskite solar technology, which it has been working on for over seven years.

Merfeld believes the industry is finally reaching a turning point where this technology could become commercially viable. “For the first time in a long time, it seems that the industry is coalescing around the realisation that there’s a real opportunity here for perovskite to not just be fascinating, but also practical and ultimately of economic value to the solar industry,” she says.

The company has been scaling a two-terminal perovskite-on-silicon tandem solar cell with high-throughput processes. “We stopped doing any kind of lab demonstrations, whether small-scale or one-offs, several years ago,” Merfeld explains. “We’re now focused on having a high batch median efficiency with very tight distribution.”

In May 2025, Qcells announced what it heralded as a significant breakthrough: that its perovskite-silicon tandem cells had passed all critical IEC tests, as confirmed by third-party certifier TÜV Rheineland. While Merfeld cautions that these tests represent “a relatively low bar for durability” and don’t necessarily confirm a 25-year lifespan, it was an important milestone as the first time anyone had passed these tests with third-party verification.

“Since then, we’ve got demonstrations in the field within our own test facilities that show really good stable outdoor performance,” she adds. “We’ll be coming up on a year here soon for some of our longer, earlier module test fields.”

When asked about commercialisation timelines, Merfeld is careful not to make specific predictions but emphasises that the company is focused on establishing bankability—proving the technology’s reliability and durability over timeframes significant for financing.

“We’re doing work within the company with partners to build those proof points and develop the models that can be used for energy yield analysis and that are confirmed by time in the field,” she explains.

Some have argued that the significant remaining scope for efficiency gains and cost reductions in crystalline silicon PV may hold back the adoption of the new generation of perovskite-based technologies. Merfeld agrees that c-Si PV will indeed be a major player for some time to come. But with overall demand for solar power likely to continue growing for the foreseeable future, she argues that the moment for perovskite-based technologies will undoubtedly come.

“There will be a tremendous amount of value created when this next generation of [c-Si] technology is even upgraded to the next phase,” Merfeld says. “That being said, perovskite, I think, still has a pretty significant opportunity in the market, because the market is going to be growing so much faster than it ever has. We’re going from a terawatt to two terawatts, and we’ll get to three terawatts in half the time it took to get to two. And the amount of power that we need from solar is increasing steadily, so we’re not saturating the world’s demand for solar in any fashion.”

That said, rather than a sudden market introduction, Merfeld expects a more gradual rollout involving partnerships with early customers to build confidence and generate data. “By the time it might be on the market for sale to a mass customer base, it will already have had a significant amount of confidence built up and data generated with at least one or two partners or customers.”

As for perovskite’s long-term potential, Merfeld sees it playing a significant role in the solar market within the next decade. “This mid-step of perovskite on silicon will actually have a pretty significant role in the market in the next five years. It will be emerging anywhere from three to five years to be measurable and impactful, and then between five to ten years, it could take over a dominant position.”

Beyond solar PV: Qcells’ broader energy solutions

While Qcells is historically known as a module manufacturer, the company has evolved into a comprehensive clean energy solutions provider with activities spanning the entire value chain.

“We have a part of our Qcells business called Axia that partners with solar sales and installation companies and supports them with professional services, order fulfilment, and lifecycle management,” Merfeld explains. This division works alongside Qcells’ financial services arm, Infin, to “make it easier for people to go solar”.

The company also offers energy-as-a-service solutions and has developed the Qcells Geli Energy software platform, which includes tools for system design, performance optimisation and real-time energy monitoring. The platform’s flagship product, Geli Predict, is a modelling and simulation platform for solar and battery systems that offers high-accuracy projections using AI to support decision-making for developers, analysts, and investors, Merfeld explains.

Additionally, Qcells manufactures US-made racking and mounting systems through its Flex Rack division and provides EPC (engineering, procurement, and construction) services for utility-scale projects across the United States.

“We’re evolving to be an energy service provider, not just a module manufacturer,” Merfeld summarises. “That evolution of Qcells—not just upstream to control our own supply chain, which is what we really hear a lot about in the press, but the more important downstream flow to create more value—that’s the future of Qcells.”

As the solar industry continues its rapid growth trajectory, Qcells appears well-positioned to capitalise on both the immediate opportunities created by US manufacturing incentives and the long-term potential of next-generation solar technologies.

PV CellTech will be held on 7-8 October in the San Francisco Bay area. For full details, click here. PV Tech readers can enjoy a 20% discount on conference registration using the code PVTech20.