SPONSORED: As the largest monocrystalline silicon manufacturer, LONGi Group has been at the forefront of the development of monocrystalline silicon cell technologies. These technologies are not limited to the monofacial P-type PERC cells (such as LONGi's Hi-MO1), but also incorporate the innovative bifacial PERC cell (Hi-MO2), which will be discussed in detail in this article.

The technology of Passivated Emitter and Rear Cells (PERC) originated from the 1990s and since then monocrystalline PERC has become increasingly popular due to its great efficiency. According to Taiwan based market research firm EnergyTrend, PERC capacity will reach 61GW and account for 44% of market share by 2020.

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

Based on research conducted by German institute ISFH, the efficiency of mass-produced monocrystalline P-type PERC cells could reach 24%, approaching that of those using HIT and IBC technology.

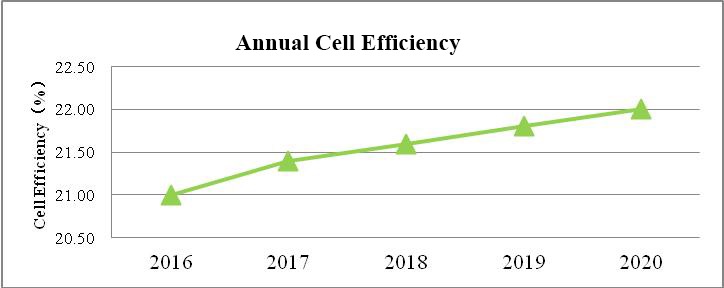

Currently, LONGi production P-type mono-facial PERC cell efficiency, as well as bifacial PERC cell front side efficiency, has reached 21.3% on average. The bifacial PERC cell rear side efficiency remains at 16%-16.5%, 75% of that of front side. Moreover, the power of the 60-cell conventional PERC module (glass/backsheet) reaches 312.1W, while the bifacial PERC module with double-glass lamination could produce 307W from the front side and 234.1W from the rear side.

In 2018, the production efficiency of monofacial PERC cells as well as bifacial cells will reach 21.6%. According to LONGi, PERC cell production efficiency will go up to 22% on the front side and 17.5% for the rear side by 2020.

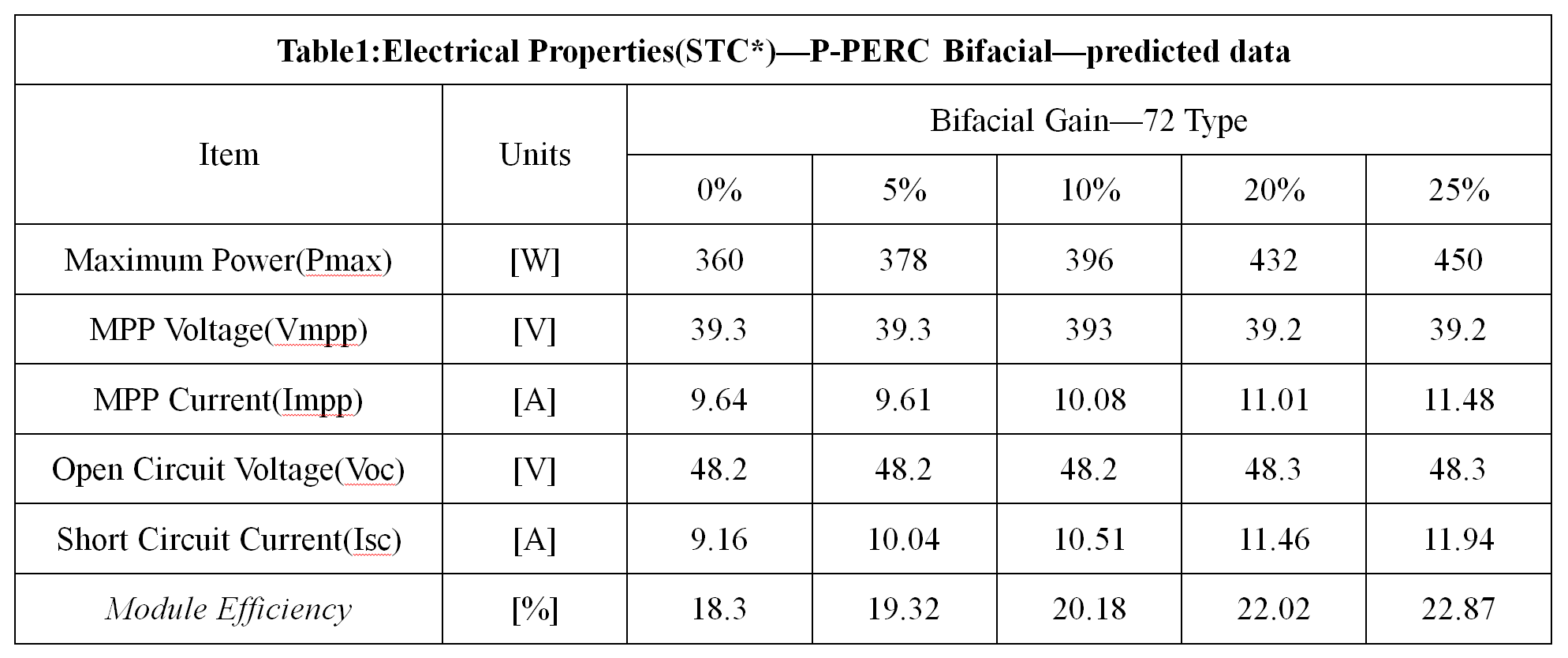

Bifacial PERC modules are known to utilize the reflected and diffuse light reaching the rear surface to generate electricity. However, a number of factors may interfere with the light arriving at the back side of the modules. We investigated the influence of various topographical characteristics and reflectivity on bifacial power gain. This reveals that the module (72-cell) power will reach up to 450W when the reflectivity value is 25%, as shown in Table 1, which verifies LONGi bifacial modules’ impressive photoelectric conversion performance.

According to our experimental data, the conventional Mono PERC module has demonstrated ~3% higher energy yield than a multi-crystalline module. This can be attributed to Mono PERC's lower temperature coefficient, lower operating temperature and better low light performance. In outdoor field testing, the rear side of bifacial PERC modules could generate 14.9% more power output than mono-facial modules with fixed mount. Additionally, the rear side of LONGi's Bifacial PERC module (Hi-MO2), combined with a tilted single-axis tracker, is capable of generating 21.4% more power output than multi-crystalline modules (also with tilted single-axis tracker).