Researchers at the Massachusetts Institute of Technology (MIT) have found a new approach to identifying long-lasting perovskite formulation, opening the door for further studies that could support the US’ solar manufacturing sector.

By synthesising and testing less than 2% of the combinations among three components making up perovskite material, the researchers believe they have found what appears to be the “most durable” perovskite solar cell material to date.

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

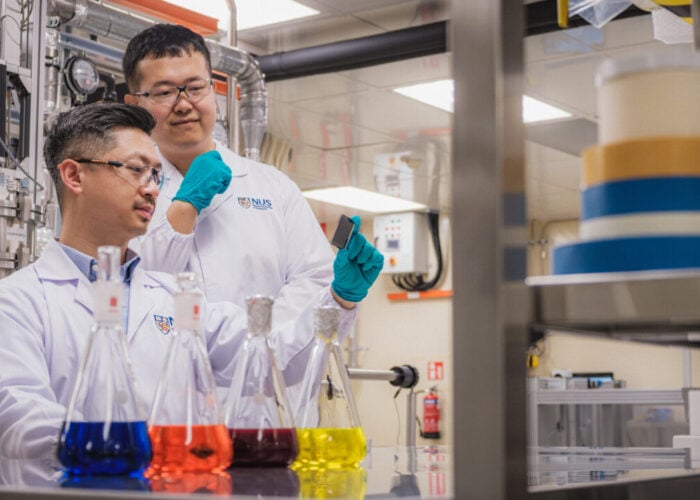

The team, which includes researchers at MIT, the Helmholz Intitute in Germany, the Colorado School of Mines, Brookhaven National Laboratory in New York, the Singapore-MIT Alliance for Research and Technology, and Germany’s Institute of Materials for Electronics and Energy Technology, used a new “data fusion” approach to guide the production and testing of different perovskite formulations. It is hoped the method, which uses automation and machine learning, will speed up the lengthy and complex process of assessing the degradation of perovskite materials.

Some laboratory experiments, the researchers said, found materials with a longevity “as much as 17-times greater than the baseline formula they started with”, while the full solar-cell demonstration found some new materials to be more than three times as long-lasting as existing perovskite structures.

The researchers’ data fusion approach uses an automated system to run through formula production and testing, and then uses machine learning to go through the test results and guide the following round of experiments. The system repeats over and over, refining the results on each experiment.

Tonio Buonassisi, a principal investigator at the Singapore-MIT Alliance for Research and Technology (SMART), said that some aspects of perovskite’s structure can be so easily varied in their composition, the number of possible structures, and therefore levels of durability between materials, becomes “just preposterous”, and therefore impractical to research without automation.

“If you consider even just three elements, the most common ones in perovskites that people sub in and out are on the A site of the perovskite crystal structure,” Buonassisi said, adding that most researchers have stayed relatively close to known formulas that have achieved high efficiencies as opposed to less common variants of perovskite.

“Once in a while, somebody makes a mistake or has a stroke of genius and departs from that and lands somewhere else in composition space,” he said, “but it’s not usually a structured thought process.”

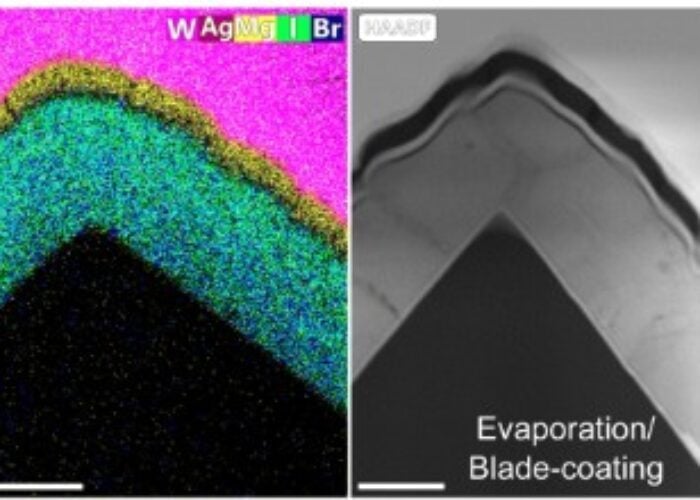

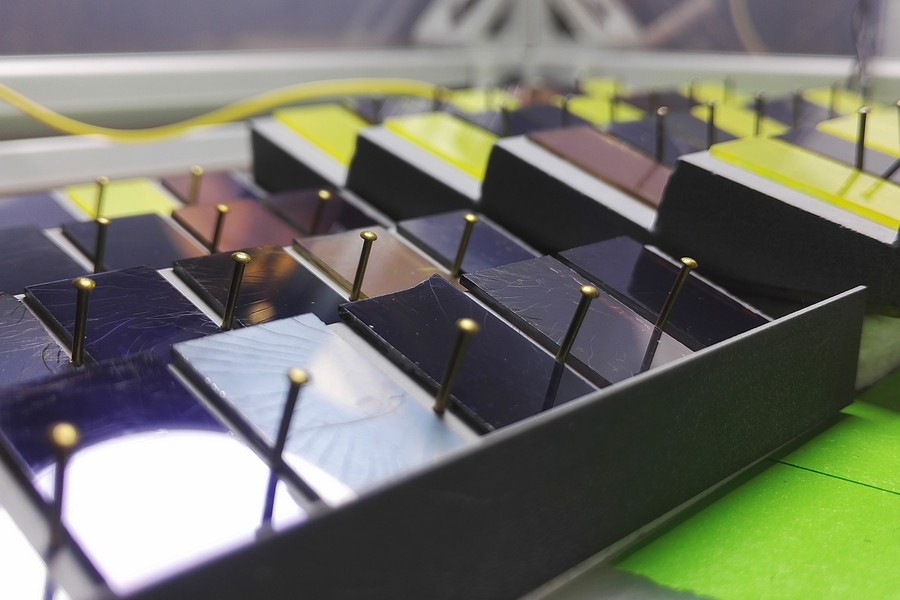

As part of the research, the team developed a high-throughput automated degradation test system that monitored the breakdown of the material through changes in colour as it darkens. The researchers also incorporated the material into a working solar cell to see its durability in a real-world scenario.

MIT postdoc Shijing Sun, who led the international team, said the experiment demonstrates how perovskite can be applied “all the way from the chemical selection until we actually make a solar cell in the end.”

“It tells us that the machine-learning-suggested chemical is not only stable in its own freestanding form. They can also be translated into real-life solar cells, and they lead to improved reliability.”

The findings were revealed days after the US’ new Energy Secretary, Jennifer Granholm, outlined a US$128 million funding package for research and development within the country’s solar manufacturing sector. Some US$40 million will be allocated to 22 projects directed at making perovskite-based solar technologies more efficient, cheap and durable. The Department of Energy said last week that perovskite solar cells (PSC), a type of solar cell which includes a perovskite-structured compound as the light-harvesting active layer, have the “potential to make highly efficient thin-film solar cells with very low production costs.” It had already set aside US$20 million to advance perovskite solar photovoltaic technologies last August.

Buonassisi said the method could “open the door” for new modes of faster, automated research involving similarly large ranges of choice in material composition.

“Once you zero in on the right composition, you bump it up into a longer loop that involves device fabrication, and you test it out” at that next level.