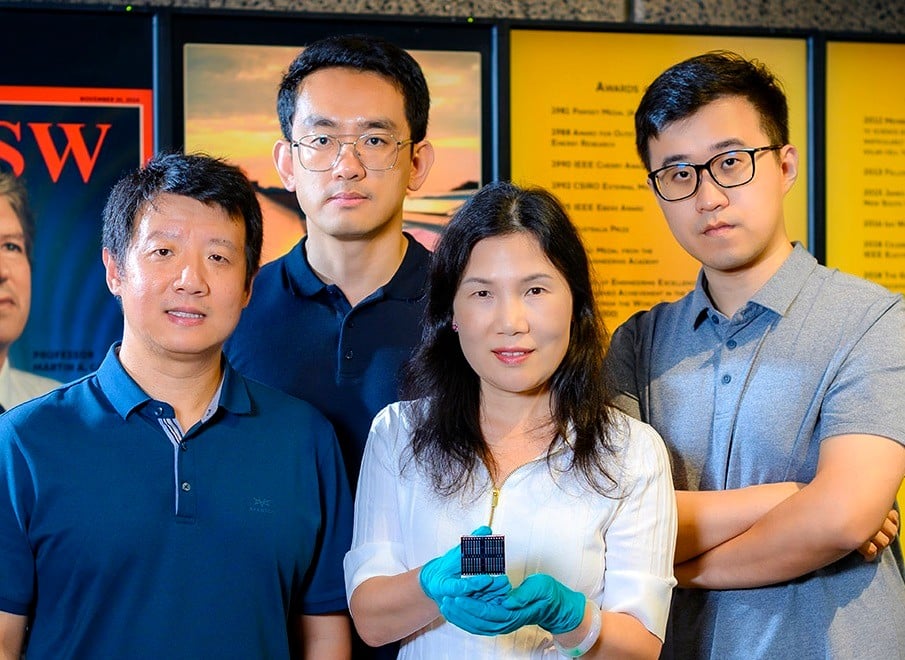

In January 2025, a group of scientists and engineers from the University of New South Wales (UNSW) claimed a new world record for photovoltaic efficiency using high-bandgap kesterite solar cells.

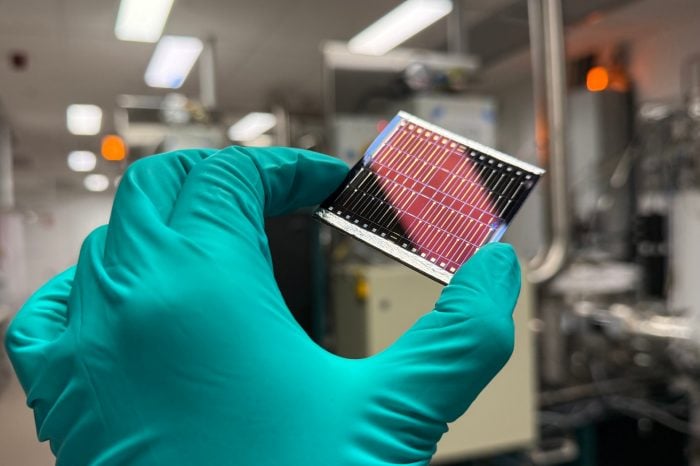

The team from UNSW’s School of Photovoltaic and Renewable Energy Engineering announced a best-ever efficiency of 13.2% for high-bandgap kesterite solar cells enhanced with hydrogen.

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

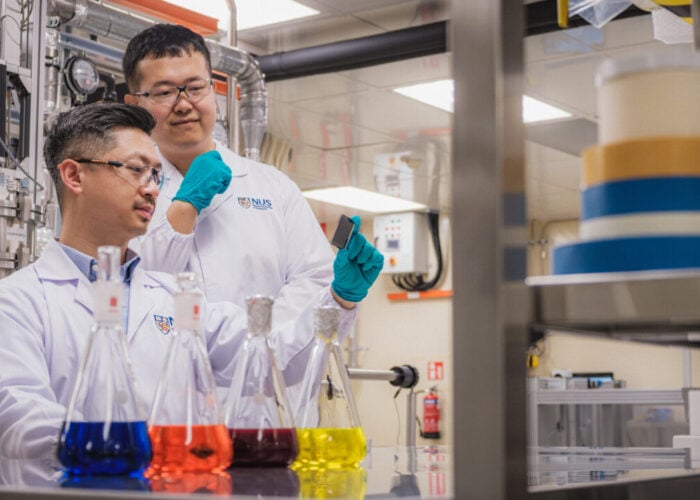

Kesterite, or copper zinc tin sulfide (CZTS), is a naturally occurring mineral but can also be artificially created at low cost by combining copper, zinc, tin and sulphur.

Previous research has shown that kesterite fulfils the prerequisites for high-efficiency solar cells. CZTS technology can maintain its photovoltaic performance over an extended period and has been touted as a potential improvement for silicon-based PV technology.

To find out more about the technology, how it could impact the PV technology landscape and how the world-record efficiency was achieved, PV Tech spoke with Scientia Professor Xiaojing Hao, who led the team behind the breakthrough.

The commercialisation of kesterite solar cells by 2030

Hao explains that if efficiency can be pushed to around 20%, there would be an excellent opportunity to commercialise the technology. She is hoping to boost CTZS efficiency and break the 15% threshold in the next year before possible commercialisation by 2030. To achieve this commercialisation date for the technology, the scientists and engineers have established several milestones that must be reached in terms of efficiency.

“That’s definitely the plan [to commercialise kesterite solar cells by 2030]. We plan to push the efficiency from 15% to 17% and 20%. We would then have better confidence in commercialisation.

“A key part of this is the defect control of these materials; understanding how the defects form and also getting strategies in place to tune these.”

Hao explains that CZTS efficiency, which has remained at around 11% in recent years, has long been hampered by the number of defects created during production, which the UNSW researchers said is hard to avoid. The researchers solved this problem by annealing—also known as heat-treating—the CZTS solar cell device in an atmosphere that contains hydrogen.

Introducing hydrogen into the production method helped UNSW achieve the world record efficiency and could form the foundation of future research efforts. “We use hydrogen to remove some of the detrimental defects and turn them into beneficial point defences that can help us to minimise the carrier combination and enhance the carrier collection,” Hao explains. “That was achieved in the 11.4% efficiency, so we quickly pushed that to 13.2% – we’re quite confident in it. We should be able to achieve 15% soon.

“Because hydrogen is modulating the defects within CZTS, that’s what helps increase its efficiency in terms of converting sunlight into electricity.”

Could kesterite rival crystalline silicon and perovskite?

One of the most significant discussions around kesterite is its potential future role in the solar PV market. Could the technology rival the dominant crystalline silicon and emerging perovskite technologies, or is it likely to play a complementary, bit-part role in the energy transition? Professor Hao believes it will ultimately come down to cost.

“The first thing for the market to accept with a new PV technology is cost. You need to achieve high efficiency, reduce the manufacturing cost and continue to reduce these costs further. Silicon has already gone through all of these cycles, and so many companies are getting reduced costs.”

One advantage Hao notes of the research her team has been doing into kesterite is that it has started from the bottom and worked upwards, first considering the key attributes of a ‘perfect’ material first and building efficiencies from that starting point. This is in contrast, say, to efforts to commerialise perovskite technologies, which have largely been top to bottom; high efficiencies achieved from the outset have been undermined by the fact that issues with the material’s stability were not ironed out to begin with. Stability remains a key stumbling block for the commercial roll-out of perovskite PV technologies.

“We know that [CTZS] is a good material. When we consider the requirements from the bottom up, we know that we need something that is widely abundant, that is environmentally friendly, that has good optoelectronic properties and can last a long time – and CZTS fits the bill,” Hao said.

On the question of where kesterite will fit into the solar technology landscape, Hao believes the solar market will likely be dominated by silicon-based solar cells.

“We’re trying to push the quality to the limit and testing stability to work out what the next generation of PV will be. I believe silicon-based solar cells will still dominate the PV market. But a big worry for the industry is what the research community does next.”

This was also alluded to when announcing the world-record efficiency for kesterite solar cells. At the time, Hao said: “Silicon modules have almost reached the limit of their theoretical efficiency, so what we are trying to do is answer the question coming from the PV industry as to what the next generation of cells will be made of.”

“And as well as that, how can we make solar panels less expensive to manufacture, and how can we get more electricity per area so the panels can be particularly beneficial for area-limited PV applications?”

Although the university achieved a world record in kesterite efficiency, Hao notes that other institutes are also pushing the boundaries of innovation with kesterite by other means, including lowerbandgap technology.

“I follow a lot of work done by institutes within the kesterite community, and they’re also pushing efficiency. One of them is pushing efficiency using lower bandgaptechnology. This is an excellent initiative because it has no stability or sustainability issues,” Professor Hao says.

Ultimately, Hao believes the greatest promise of kesterite technology is in tandem solar cells, accompanying another photovoltaic material such as crystalline silicon to boost conversion efficiencies. In this vein, Hao and her team are also engaged in research into perovskite technologies, which are also seen as a promising partner to silicon in tandem cells.

“Overall, I think we should be looking into all different types of materials for the top layer of tandem cells. That’s the only way we can maximise our chances of success and accelerate the speed towards obtaining highly efficient tandems that we can use long into the future,” she said.