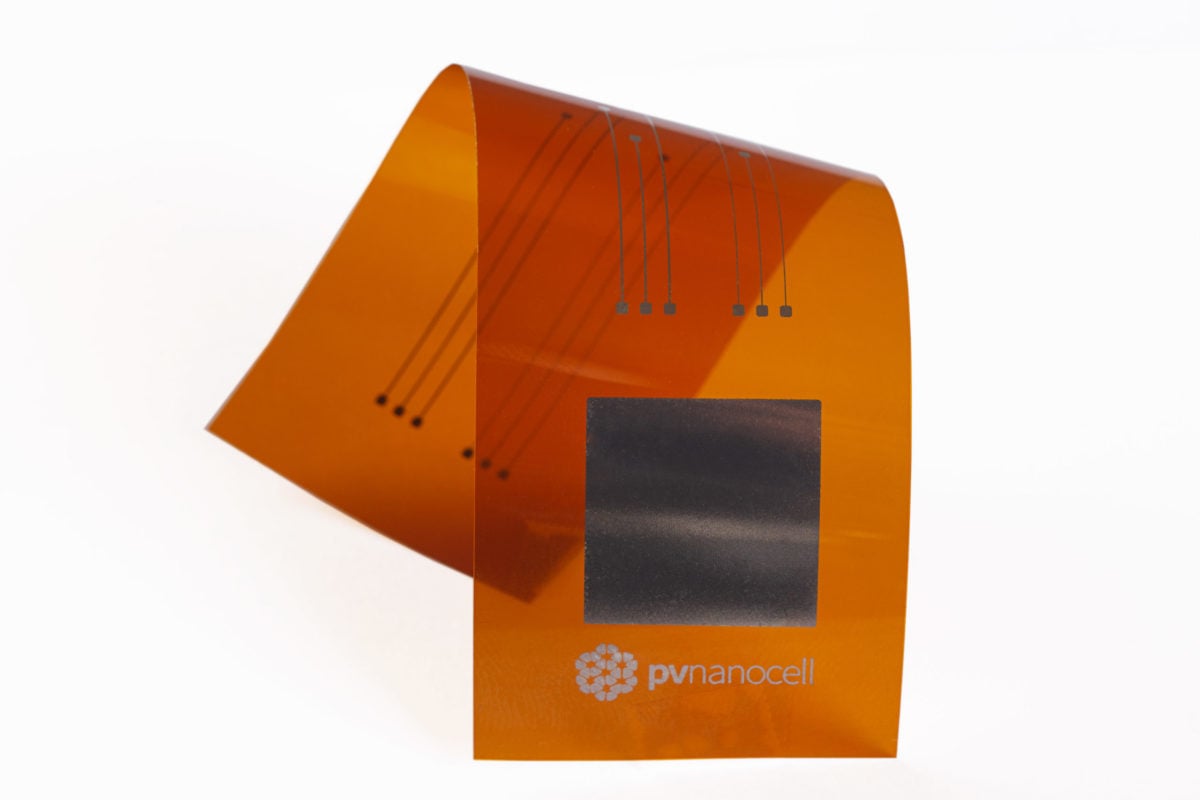

PV Nano Cell has commercially developed ‘Sicrys’, a single-crystal, nanometric silver conductive ink delivering enhanced performance for digital conductive printing in mass production applications. The inks are also available in copper-based form, delivering all of the product’s properties and advantages with improved cost efficiency.

Problem

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

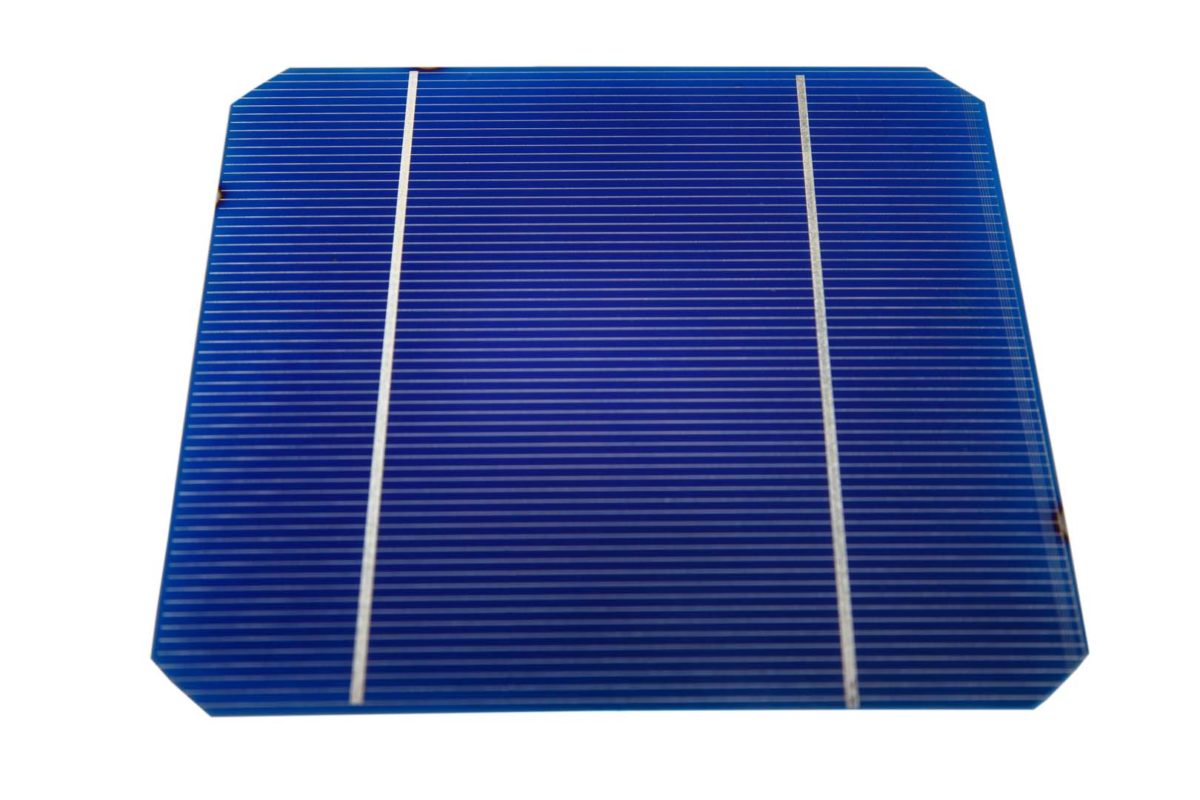

Solar cell metallization is not yet fully optimized for cost and resource conservation. Cell producers currently endure silicon cell breakage during cell metallization, and higher-than-necessary costs for silver. Traditional screen printing of conductive grid lines involves direct contact with brittle cells, resulting in breakage and silicon waste. Additionally, the current technologies for metallization create lines that are wider and thicker than necessary, inflating silver costs.

Solution

PV Nano Cell’s Sicrys inks enable non-contact digital inkjet printing rather than traditional screen (or stencil) printing. A transition to inkjet printing will allow a reduction in silver consumption per watt by printing narrower lines, controlling accurately the pattern thicknesses and increasing the cell efficiency. Moreover a reduction in cell breakage rate is expected which will in the future allow the reduction of the wafer thickness, which can save on the amount of expensive silicon required for each cell.

Applications

Sicrys inks are highly adaptable, with 2D and 3D applications including metallization of solar photovoltaics as well as printed circuit boards, sensors, RFID, smart cards, antennas, advanced packaging, and touchscreens.

Platform

Sicrys inks enables metallization of solar cells with inkjet printing. The silver loading is said to be higher than that of other inks on the market, and comes with exceptional conductivity and low viscosity, ideal for digital inkjet printing applications, while also offering the longest shelf life in the industry, according to the company. PV Nano Cell offers both silver and copper conductive inks; Sicrys copper conductive offers a unique, low-cost replacement for silver ink. The production of the Sicrys inks involves low energy consumption and yields no hazardous wastes, a ‘green’ and efficient process.

Availability

Currently available.