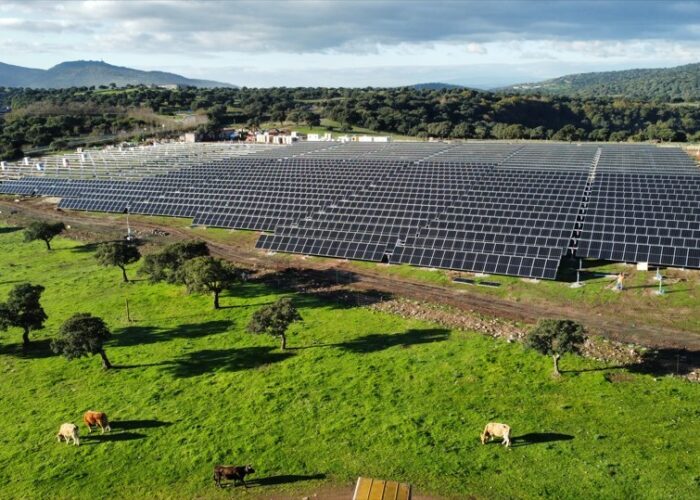

Last month, PV Tech and ‘Solar Module Super League’ member JinkoSolar co-hosted a webinar which explored the benefits of TOPCon PV modules in relation to utility-scale solar LCOE.

JinkoSolar’s Roberto Murgioni discussed the properties of the company’s TOPCon HOT2 technology compared to traditional Mono PERC cells and modules, while TÜV NORD’s Shawee Wei presented the results of a study the technical advisory conducted which compared the performance of n-type and Mono PERC modules in the field.

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

The webinar can be watched on-demand below, however we also took some of the most popular questions from the audience of the webinar for both Murgioni and Wei to answer in more depth and detail.

PV Tech: Can you provide a bit more detail around the LCOE considerations for TOPCon modules and the benefits they provide compared to Mono PERC?

Roberto Murgioni (RM): Jinko Solar’s portfolio is always focused on products that contribute to a lower levelised cost of electricity (LCOE). In terms of modules, our main families are produced on 182mm wafers and our new series, Tiger Neo, will bring n-type TOPcon technologies to mass production, with products also suitable for utility scale.

The Tiger Neo series brings more power per panel and more kWh per watt combined with significantly improved reliability under any real-world conditions, making it more valuable for PV project owners. We decided to make a stronger transition into n-type after gaining maturity and experience in this technology.

Beyond higher efficiency potential, the implementation of these cells at module level has clear advantages that we are confident will translate into a LCOE at project level. Tiger Neo TOPCon modules have an optimal power temperature coefficient (-0.30%/°C) and operate at 1°C lower temperatures compared to p-type modules, which means less temperature losses at operating conditions. Laboratory tests and outdoor results have also shown a clear advantage in low light conditions, which could translate into extended power generation for one hour in the early morning and late afternoon. In the case of bifacial modules, Tiger Neo’s improved bifaciality factor also means higher bifacial gain.

The average energy gain of between 1.5%-3% produced by the Tiger NEO modules compared to PERC modules will strongly reduce the final LCOE value of a project and increase the IRR of the business plan. In addition, TOPCon modules have negligible light induced degradation (LID) and high light-elevated temperature-induced degradation (LeTid), along with improved reliability performance, allowing us to offer an enhanced 30-year warranty, 1% degradation in the first year and only 0.4% linear degradation per subsequent year.

The key benefit delivered by TOPCon HOT2 technology is the surplus of energy compared to p-type that, in the case of bifacial products, represents 3% higher output. This will significantly reduce the cost of energy, considering the total cost of investment is very close to p-type for large scale plants.

Shawee Wei (SW): In relation to module sizes, consider that the length of one tracker should not exceed 90 metres. In our study, the length of the 2P tracker which the JKM610N-78HL4-BDV panels are installed on is about 87 metres, while the 2P tracker on which the Type A 665W are installed is about 80 metres. So, JKM610N-78HL4-BDV will install 19% more DC capacity per tracker. This reduces the initial investment. And then, in terms of module efficiency, higher energy generation during the life-cycle of JKM610N-78HL4-BDV is the most critical factor in reducing the LCOE.

How does Jinko Solar expect TOPCon to compare with heterojunction further down the line, with TOPCon having greater cost synergies with existing PERC lines, but HJT potentially offering higher efficiencies?

RM: Our TOPcon HOT2 technology has just started, and we see very high potential for improving it rapidly at a reasonable cost, similar to p-type technology. We do not see the same path for HJT, which we do consider a very good technology, but more difficult to implement on the existing production lines and with higher cost impact, resulting in a difference in the commercial cost between the two of about €0.5/W.

What is the reason behind offering 72-cell and 78-cell formats of the Tiger Neo range?

RM: It’s offering flexibility for the designer and investors. Large scale plants may differ depending on mounting structure, DC architecture, space limitations and environmental conditions, so by offering two products our clients can compare the impact on the LCOE of both and select the one which is performing better.

With a separate range targeted at the residential and C&I market, what is the potential market for TOPCon modules for these sectors?

RM: Residential and C&I markets are constantly growing in Europe and are also becoming more and more demanding in terms of efficiency and performance. They usually face available surface constraints because of the inherent nature of rooftops, so optimising for them is a must.

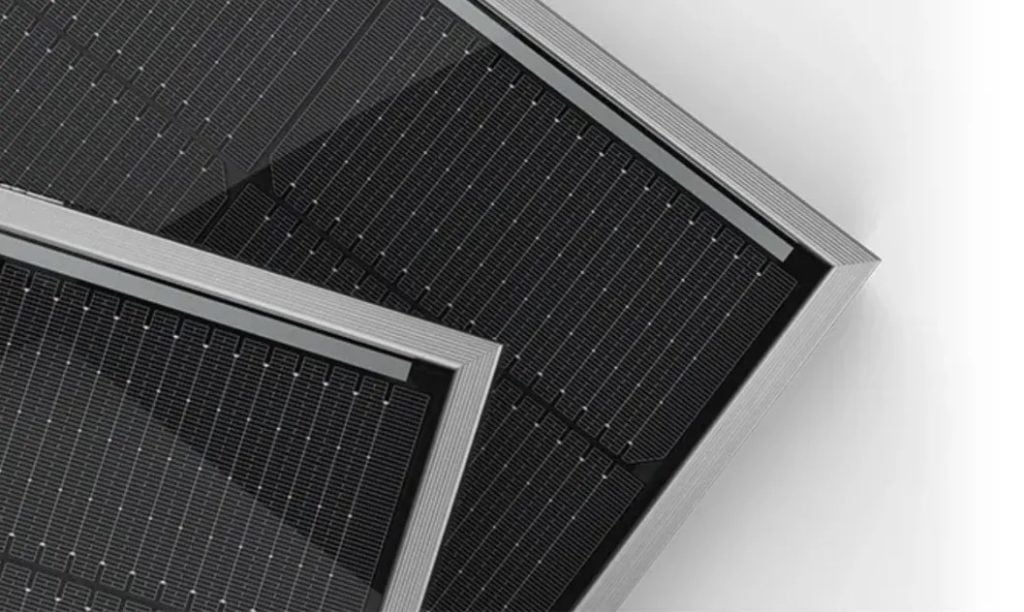

Tiger Neo 54 modules have been specifically designed to meet the needs for residential applications and commercial distributed generation. The new module delivers a maximum power output of up to 415Wp in mass production, with an ultra-high conversion efficiency of up to 21.25%. Tiger Neo also scores high from the design aesthetics point of view. The all black panel’s metal gridlines are almost invisible on the surface, which makes them easier to visually integrate on rooftops to meet architectural requirements.

There’s been a lot of discussion around the benefits of TOPCon cells – lower degradation, higher efficiency – are there any potential challenges compared to more traditional PERC cells?

SW: Compared to PERC, TOPCon products are more sensitive to water and PID, and manufacturers need to fully verify the reliability of different BOMs and process quality control. It is also a challenge for third-party laboratories to accurately test the parameters of TOPCon products.

RM: The target for TOPCon was to improve the efficiency of cells , and to avoid complex cell structures. So by using the standard structure of a crystalline Si cell, we optimise the use of light and minimise carrier losses, which are caused by high resistance in transportation of current and carriers in the cells. This is achieved by constructing an effective conductive emitter, one that is highly selective to enable the transport of free carriers with a high reduction of recombination and resistance. New passivated contacts transport the current with lowest resistance, hence the recombination rate is much lower than in standard BSF constructions like PERC.

The optimised cell surface layers with electrical parameters to reduce light reflection enforce current transport, minimise carrier recombination and enhance the ability of the cells to absorb light in a wider spectral range compared to PERC cells.

TOPCon technology can easily be transferred into production by using PERC production machines, with the only major difference being the tunnel oxide layer which is a new production step. This is done by thermal oxidation of Si that produces a thin layer – only a few millimetres thick – of SiOxide, the tunnel passed from carriers by use of quantomechanical tunnel processes.