A shift of focus within the solar manufacturing industry towards sustainability across the entire supply chain is essential, according to the CEO of German wafer producer NexWafe.

In a guest article published today on PV Tech, Davor Sutija, CEO of Freiburg-based NexWafe, said the reshoring of critical manufacturing steps – especially polysilicon and wafers – “intersects with environmental considerations” and also offers long-term economic benefits.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

Sutija said the upstream steps in the solar supply chain, patricularly polysilicon production, solar ingots and wafers require higher investment, take longer to be operational and are more energy intensive than a module assembly line.

“Even more disruptive approaches to wafer manufacturing are moving into pilot production in 2025,” wrote Sutija, adding that these approaches eliminate the polysilicon (Siemens) production and Czochralski (CZ) ingot growth, thus reducing the carbon footprint by 60%, compared with conventional processing.

Sutija said reshoring the production of polysilicon to cells using less carbon-intensive methods would reduce the amount of time takes for modules to pay off their “carbon debt” – the amount of time it takes for a module to achieve carbon neutrality. “Panels using polysilicon and wafers manufactured in a facility powered by coal can take triple the run time to become carbon neutral,” he wrote

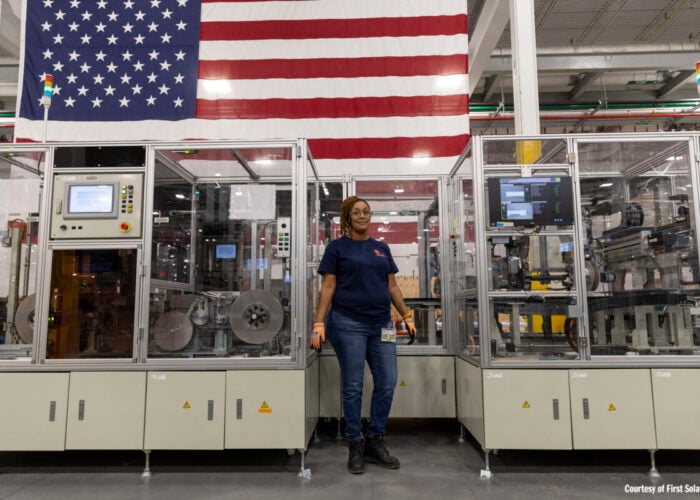

The importance of upstream sustainability comes at a pivotal moment in the US. Advisory body Clean Energy Associates (CEA) expects to reach an annual module nameplate capacity of 35GW by year’s end, a more than fourfold increase in over two years.

The Solar Energy Manufacturers for America (SEMA) Coalition recently published a report assessing the current US silicon solar manufacturing capacity which has “glaring gaps” in domestic production of modules, wafers and cells. SEMA called for a “strengthening [of] the domestic supply chain to produce solar components”.

To read the full post, visit our Guest Blog section.