Dependable solar system performance grows from good design. When designing any solar array, it is crucial to look ahead and anticipate potential shading issues and provide adequate space for inspection, cleaning and maintenance. It is equally important to select components that will not deteriorate prematurely and place undue stress on the system or compromise it altogether.

Drawing on decades of experience researching, manufacturing and testing solar materials, DuPont offers best practices for solar array design, component selection and long-term maintenance. DuPont has made these available as a free-of-charge resource to interested EPCs, roof top installers and energy solutions providers.

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

These include:

- Tips for successful solar array design

- Advice on selecting monitoring equipment for peak system performance

- Guidance on choosing inverters, cables and converters that endure

- Recommendations for specifying solar panel materials that will resist degradation from UV rays, expansion, moisture ingress and other environmental stresses

- Guidelines for safe PV array installation

- Directions for regular system inspection and maintenance

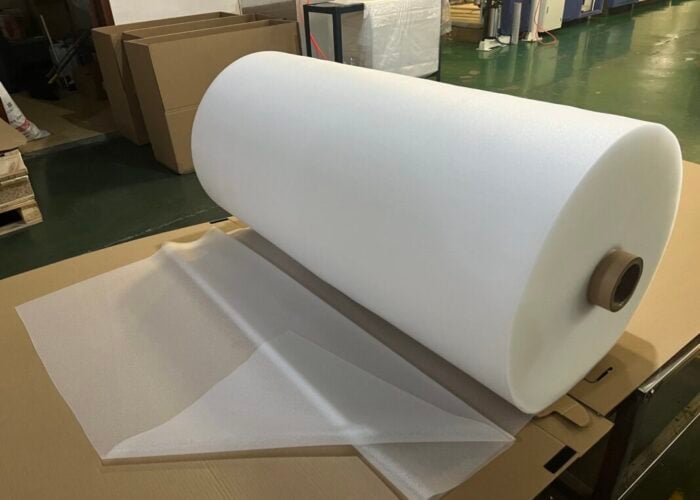

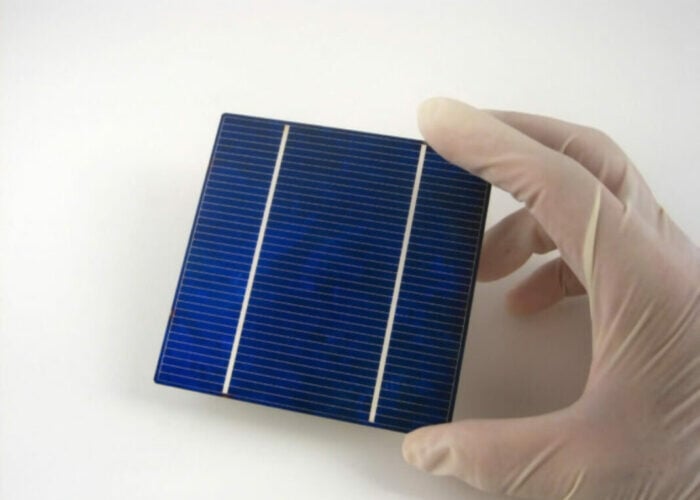

For more than 40 years, DuPont has been an industry leader in the research and manufacture of high-performance materials for photovoltaic panels. DuPont manufactures Tedlar PVF, a film for panel backsheets that has been proven in the field for 30+ years, and Solamet photovoltaic metallization paste materials, which optimize efficiency and yield for today’s solar cell designs.

To access this free resource, click here.

This article was written by DuPont and edited by PV Tech.