Selecting the appropriate Bill of Materials (BoM) is a key factor in ensuring the durability and reliability of solar panels. But relying solely on IEC certification and IEC extended test results is not enough because these accelerated lab testing protocols were not designed to predict long-term performance of panels in the field. Long-term outdoor exposure is the ultimate test for module components.

DuPont has conducted extensive field observations and laboratory testing to determine which solar panel materials withstand the test of time. Based on this information, DuPont has developed a list of BoM recommendations, which include:

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

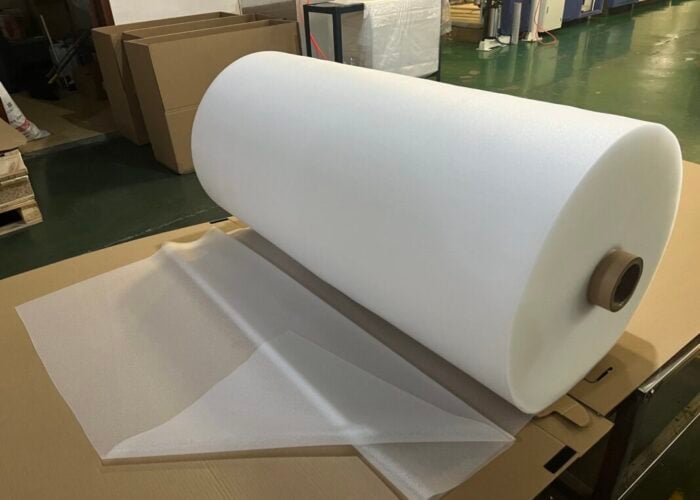

- The backsheet material should have 30+ years of proven field performance in all climatic conditions and should be made of polyvinyl fluoride (PVF) film.

- A PVF double-sided backsheet offers the best level of protection, followed by a PVF single-sided backsheet.

- A UV-resistant ethylene vinyl acetate (EVA) with a proven track record should be specified for the encapsulant.

- Silicone-based sealants that are field proven for 25+ years should be specified for sealing and fixing frames and junction boxes in photovoltaic panels.

For more than 40 years, DuPont has been an industry leader in the research and manufacture of high-performance materials for photovoltaic panels. DuPont manufactures Tedlar PVF, a film for panel backsheets that has been proven in the field for 30+ years, and Solamet photovoltaic metallization paste materials, which optimise efficiency and yield for today’s solar cell designs. Learn more here

This article was written by DuPont and edited by PV Tech.